Process for regenerating of in-situ electricity of adsorption resin

An adsorption resin and electric regeneration technology, applied in electric regeneration, filter regeneration, petroleum industry, etc., can solve the problems of high cost, high cost, and no comprehensive utilization value of high-concentration waste liquid, so as to reduce regeneration cost and simplify regeneration The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

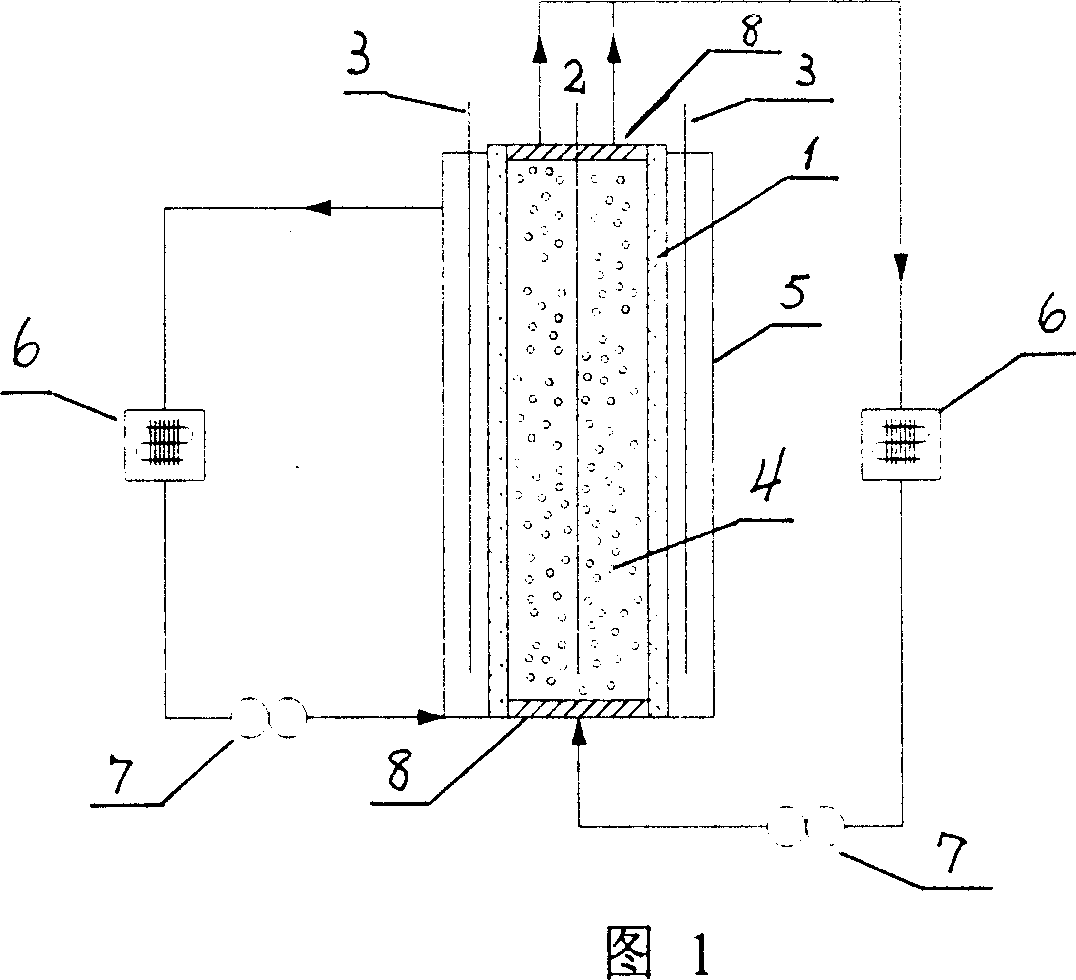

[0017] The cation exchange membrane adopts polyethylene heterogeneous cation exchange membrane (3361BW type produced by Shanghai Shanghua Water Treatment Material Co., Ltd.) to roll into a column with a diameter d of 30mm and a height h of 250mm, and is filled with NKA-2 macroporous adsorption resin ( Tianjin Nankai University chemical plant) 0.14kg. A thorny anode is installed in the resin bed, and the material is titanium base coated with ruthenium (produced by Henan Xinxiang Future Water Chemical Co., Ltd.), and the cationic exchange membrane is covered with a cathode, and the material is a titanium plate.

[0018] The adsorption resin is used to treat phenol-containing wastewater, the phenol concentration is 430 mg / l, and the chromaticity is 200 times. Resin treated wastewater 20BV, the average concentration of phenol in the effluent is 1.6mg / l, and the adsorption removal rate is 99.63%. Then in situ electrical regeneration is performed.

[0019] The anode regeneration s...

Embodiment B

[0022] The anion exchange membrane is made of polyethylene homogeneous anion exchange membrane (3362BW type produced by Shanghai Shanghua Water Treatment Material Co., Ltd.) rolled into a column with a diameter d of 50mm and a height h of 400mm, and is filled with non-polar macroporous adsorption resin (Tianjin Nankai University Chemical Factory produces H103 type) 0.6kg. A thorn-like anode is installed in the resin bed, and the material is titanium-based coating iridium (produced by Henan Xinxiang Future Water Chemical Co., Ltd.), and the anion exchange membrane is covered with a cathode, and the material is stainless steel.

[0023] The adsorption resin is used to treat aniline-containing wastewater, the aniline concentration is 360 mg / l, and the chromaticity is 140 times. Resin treated wastewater 20BV, average effluent aniline concentration 9mg / l, adsorption removal rate 97.5%. Then in situ electrical regeneration is performed.

[0024] The anode regeneration solution is ...

Embodiment C

[0027] The cation exchange membrane adopts polyethylene heterogeneous cation exchange membrane (3361BW type produced by Shanghai Shanghua Water Treatment Material Co., Ltd.) to roll into a column with a diameter d of 50mm and a height h of 400mm, and is filled with non-polar macroporous adsorption resin ( Tianjin Nankai University chemical plant) 0.6kg. A thorn-like anode is installed in the resin bed, and the material is titanium-based coating iridium (produced by Henan Xinxiang Future Water Chemical Co., Ltd.), and the cationic exchange membrane is covered with a cathode, and the material is stainless steel.

[0028] Using this adsorption resin to treat tricyclazole process wastewater, the COD is 19542 mg / l. Resin treated wastewater 12BV, average effluent COD2610mg / l, adsorption removal rate 86.64%. Then in situ electrical regeneration is performed.

[0029] The anode regeneration solution is 10% sodium chloride solution, neutral, temperature 60°C, flow rate 1BV / h, DC elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com