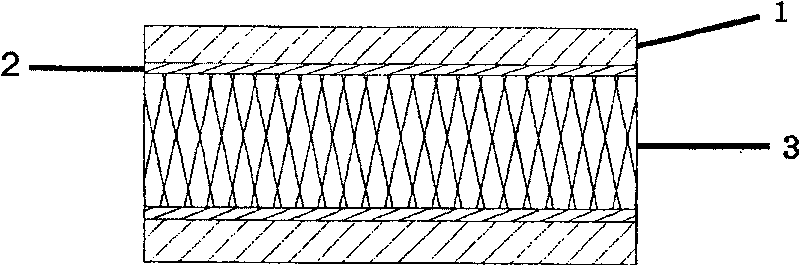

Resin composite copper foil, printed wiring board, and production process thereof

A printed circuit board, resin composite technology, applied in the manufacture of printed circuit boards, the field of printed circuit boards, can solve problems such as heat resistance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

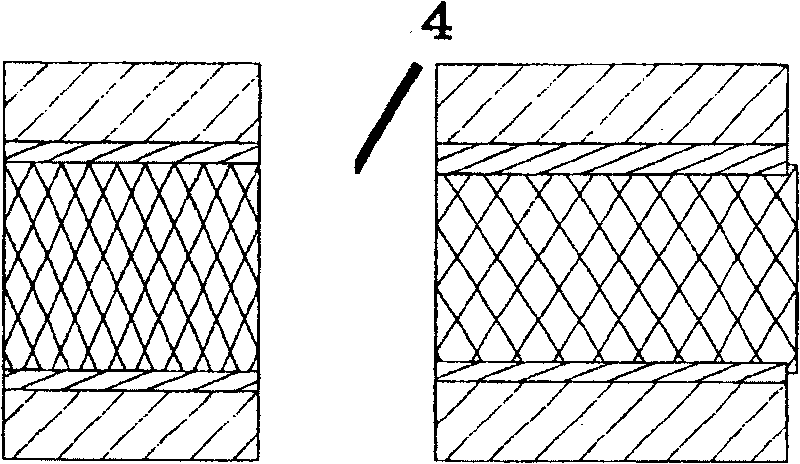

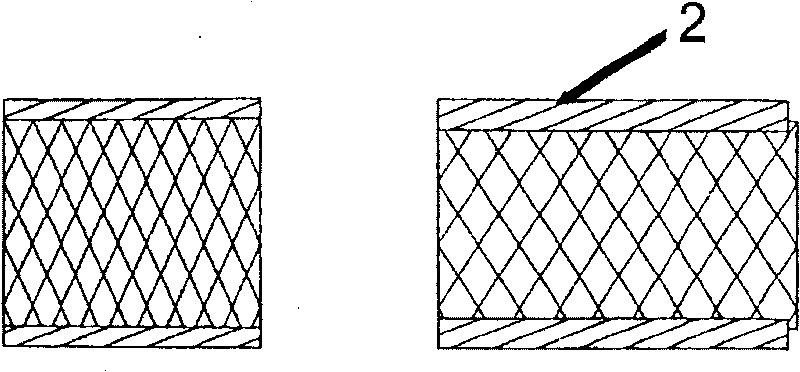

Method used

Image

Examples

Embodiment

[0055] The present invention is specifically explained below with reference to Synthesis Examples, Comparative Synthesis Examples, Examples and Comparative Examples.

Synthetic example

[0057] In a 2-liter three-necked flask with an anchor-type stirring rod made of stainless steel, a trap equipped with a nitrogen introduction tube and a stopcock, and a reflux condenser with a cooling tube with a ball mounted on the trap, add 117.68 g (400 mmol) 3,4,3',4'-biphenyltetracarboxylic dianhydride, 87.7 g (300 mmol) 1,3-bis(3-aminophenoxy)benzene, 4.0 g (40 mmol) γ-valerolactone, 4.8 g (60 mmol) pyridine, 300 g N-methyl-2-pyrrolidone (hereinafter referred to as "NMP"), and 20 g toluene. The mixture was heated at 180°C for 1 hour, then cooled to about room temperature. Add 29.42 g (100 mmol) of 3,4,3',4'-biphenyltetracarboxylic dianhydride, 82.12 g (200 mmol) of 2,2-bis{4-(4-aminophenoxy) Phenyl}propane, 200 g of NMP and 40 g of toluene, and these components were mixed at room temperature for 1 hour, and then heated at 180° C. for 3 hours to obtain a block copolymer polyimide with a solid content of 38%. The block copolymer polyimide had a formula (1): formula (2) r...

Embodiment 1-4

[0061] The block copolymer polyimide solution obtained in the synthesis example was further diluted with NMP to prepare a block copolymer polyimide solution with a solid content of 10%. According to the solid content ratio shown in Table 1, this block copolymer polyimide solution and bis(4-maleimidophenyl) methane (BMI-H, provided by K I KASEI KK) at 60 ° C They were melted and mixed for 20 minutes, whereby resin solutions were respectively prepared. The thus-prepared resin solutions were respectively coated on the matte surface of an electrolytic copper foil having a thickness of 12 µm (F0-WS foil, Rz=1.5 µm, supplied by Furukawa circuit foil Co., Ltd.) with a reverse roll coater. ), and then dried at 120° C. for 3 minutes and 160° C. for 3 minutes under a nitrogen atmosphere, and finally heat-treated at 300° C. for 2 minutes, thereby preparing resin composite copper foils respectively. On the other hand, 400 g of 2,2-bis(4-cyanooxyphenyl)propane was melted at 150°C and allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com