Domesticated and selectively bred autoflocculating yeast mutant plant and its application

A self-flocculation and Saccharomyces cerevisiae technology, applied in the field of biotechnology and microorganisms, can solve the problems of difficult control, affecting the service life of immobilized yeast, and low sugar alcohol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1 is selected from the device of flocculating yeast strain

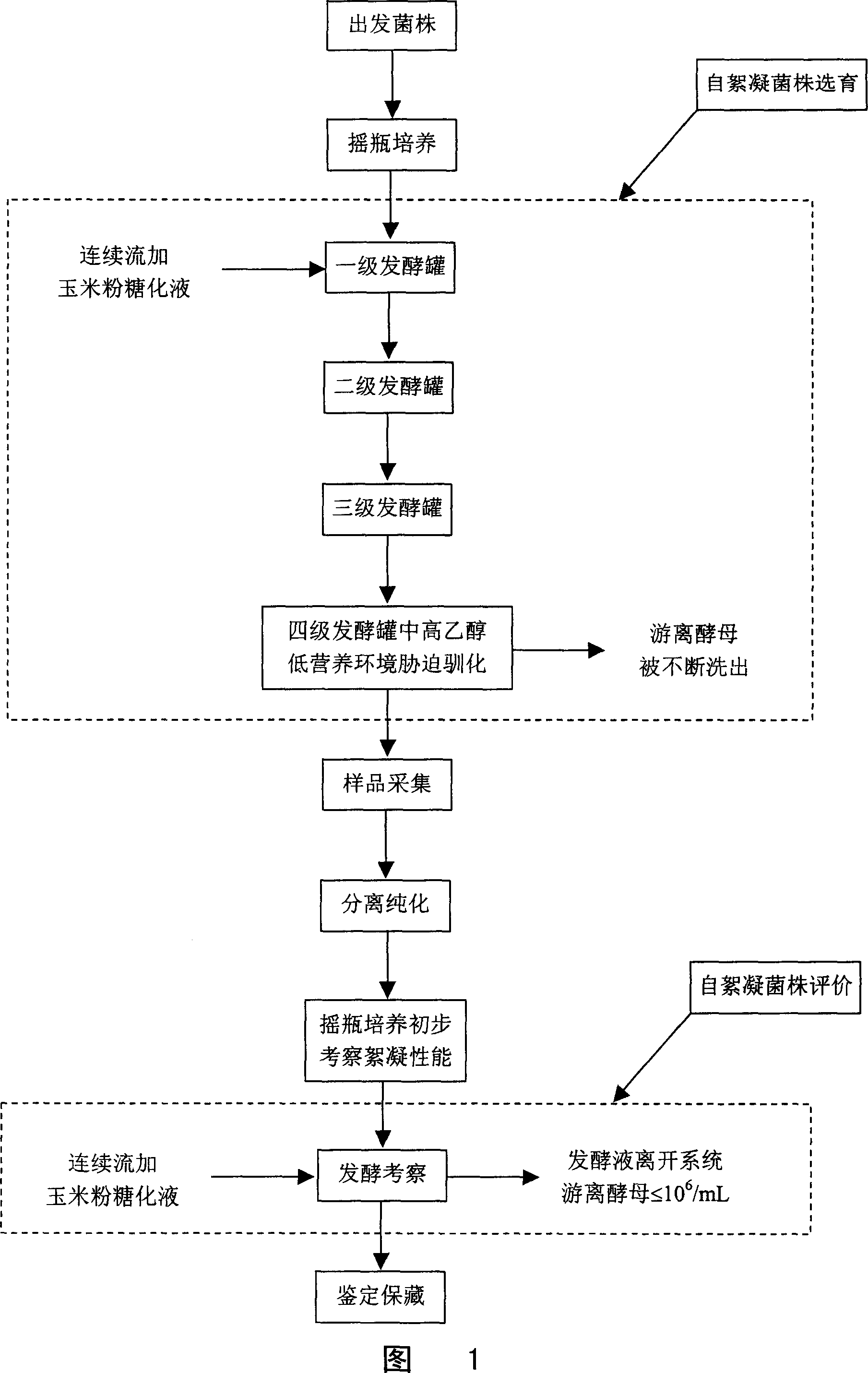

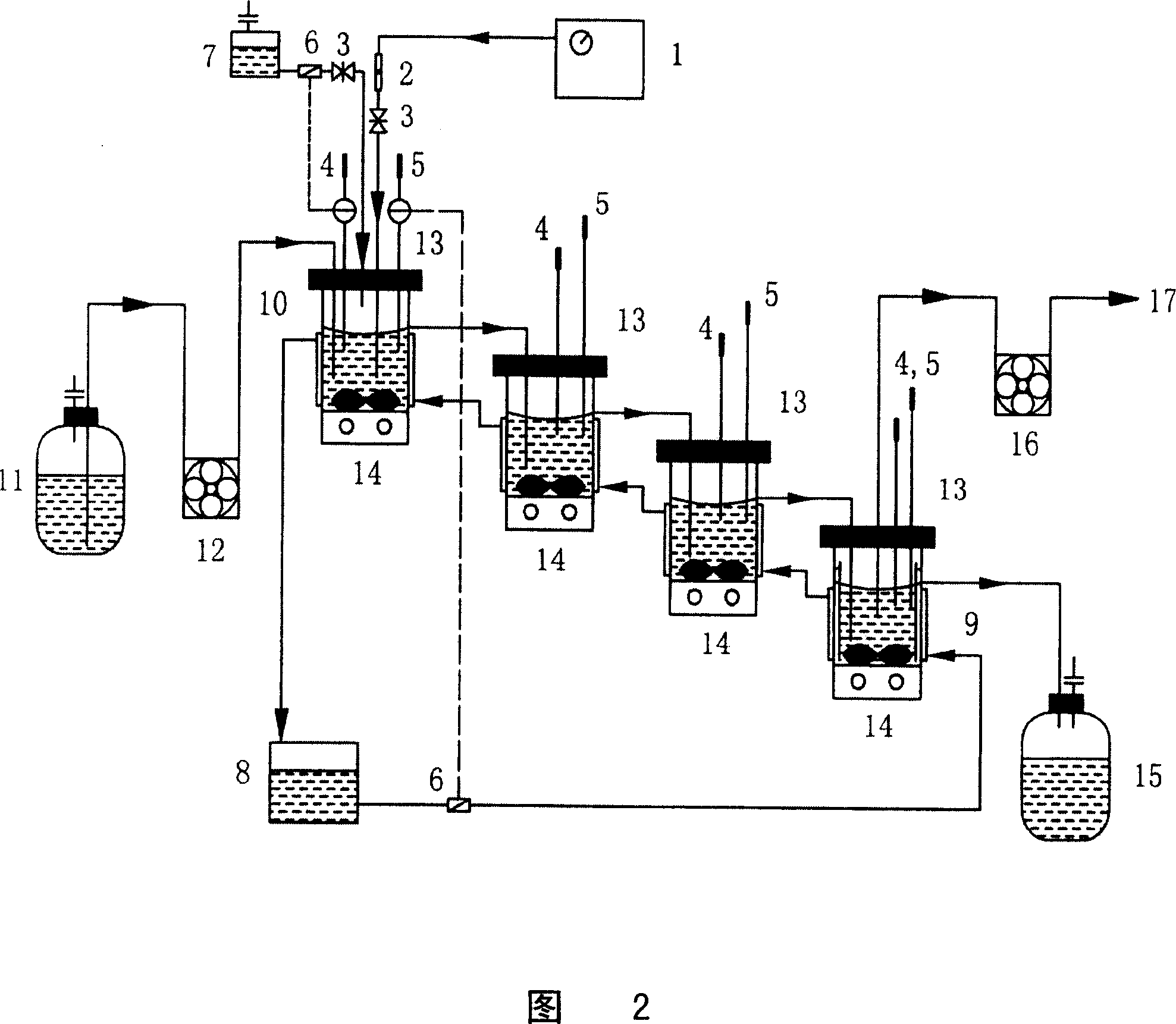

[0070] The device for breeding the self-flocculating yeast strain of the present invention is shown in Figure 2, and the device is a four-stage series fermenter system, which operates continuously.

[0071] In Fig. 2, the described device has: 1. WM-2A type oil-free air compressor; 2. Air rotameter (0-150mL / min); 3. Needle valve; 4. LP-3000pH indication and control System; 5. Temperature indication and control system 5; 6. Solenoid valve, whose specification is φ8mm; 7. Ammonia storage tank, whose specification is 250mL; 8. Constant temperature water tank; 9. Constant temperature water inlet; 10. Constant temperature water outlet; 11 1. Culture medium storage tank, which is a 2000mL triangular flask; 12. HL-2S type culture medium feeding peristaltic pump; 13. The total volume is about 1500mL (inner diameter φ110×height H150mm), and the working volume is about 1000mL (the bottom is 110mm upward. φ6m...

Embodiment 2

[0073] Breeding of embodiment 2 Saccharomyces cerevisiae mutant strain

[0074] 1. Preparation of starting strain and seed culture medium

[0075] One of the starting strains in this example is the Saccharomyces cerevisiae K2 strain commonly used in the ethanol fermentation industry. This strain has excellent ethanol fermentation performance (gifted by Dalian Distillery).

[0076] After the slant strains stored in the refrigerator at 4°C were activated at room temperature for 4 to 6 hours, they were inoculated into a 250mL Erlenmeyer flask containing 100mL of medium, and after shaking the flask at 30°C and 150rpm for 24 hours, they could grow as shown in Figure 2. Fermentation system inoculation.

[0077] The composition of shake flask culture medium is (g / L): glucose 10, yeast extract 5, peptone 3, prepared with ordinary tap water, and sterilized at 121° C. for 15 minutes.

[0078] The second starting strain of the present invention is SPSC01, and its cultivation method is ...

Embodiment 3

[0099] The preliminary detection of the flocculation performance of embodiment 3 bacterial strains

[0100] The self-flocculating yeast flo obtained in Example 1 was inoculated into the shake flask liquid medium, and cultured according to the same operation as the aforementioned yeast seed cultivation. After several hours, the shake flask was taken out, and the millimeter-sized self-flocculating granular yeast could be observed. After standing still for 2-3 minutes, the self-flocculating granule yeast almost all settled, and the culture medium was clear and transparent, which indicated that the yeast strain obtained by breeding had excellent flocculation performance. The self-flocculating yeast suspension cultured in shake flasks for 24 hours could be inoculated into the fermenter to investigate its Ethanol fermentation performance and flocculation stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com