Method for preparing hollow fiber multiporous biological titanium material

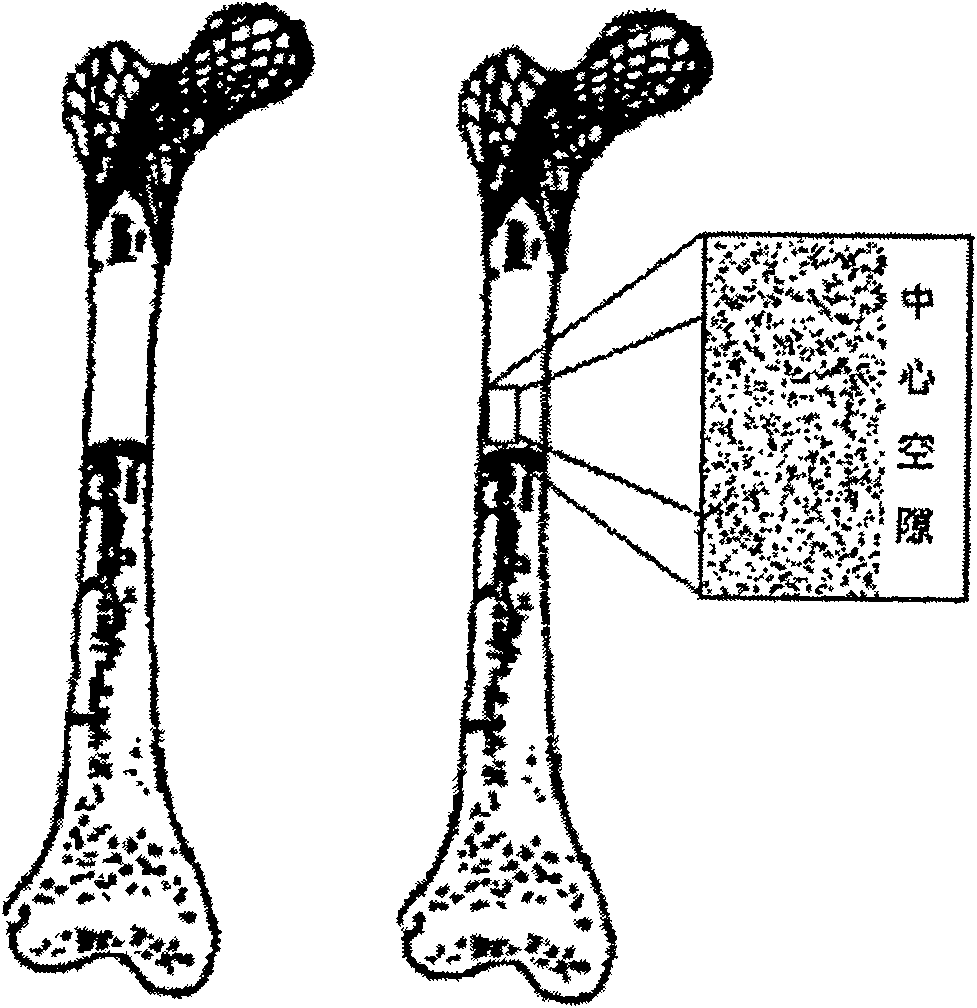

A bio-titanium and fiber technology, applied in the field of bioengineering, can solve the problems of difficult precise control of pore density and uniformity, complex process, high manufacturing cost, etc., to achieve the advantages of osteoblast adhesion, uniform fiber distribution, and lighten the The effect of stress shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

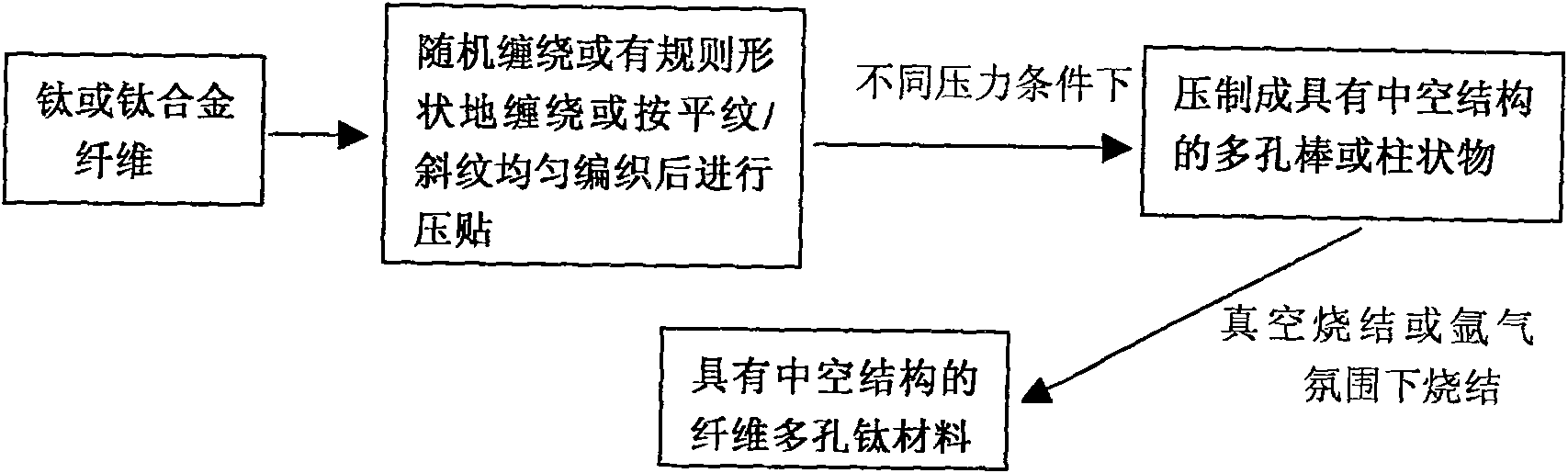

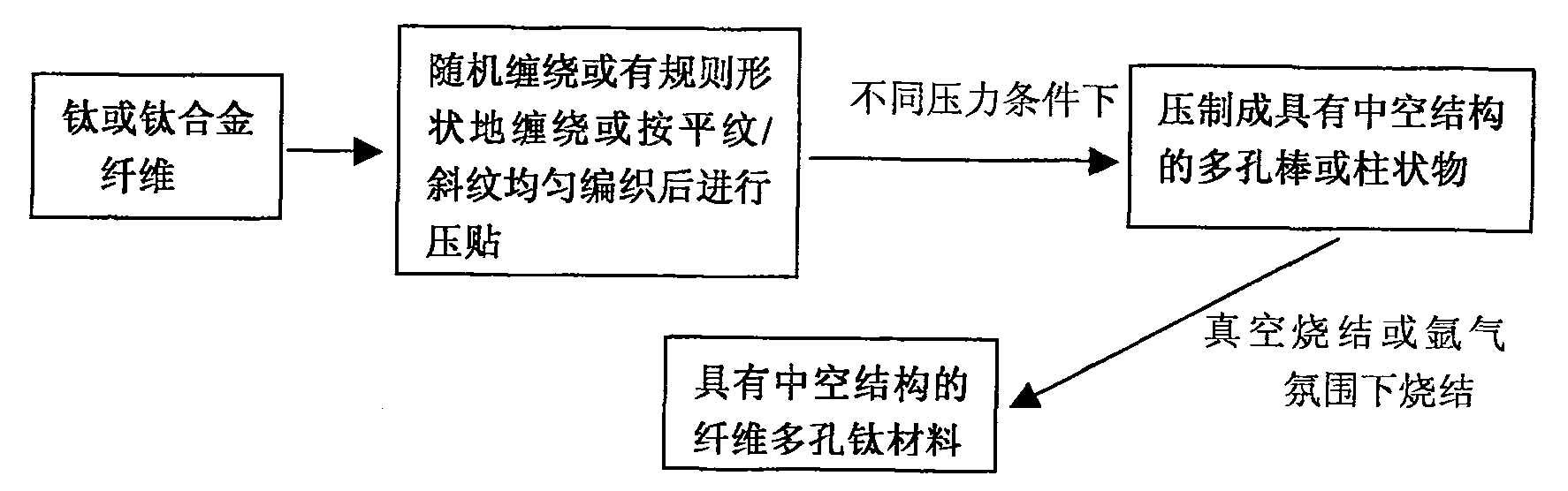

Method used

Image

Examples

Embodiment 1

[0025] The TA9 titanium alloy fiber with a specification of φ0.08mm is randomly wound on a dense mandrel with a diameter of about 8.0mm, and shaped. Put the mandrel with 20g of titanium alloy fiber wound on the surface into a steel mold with an inner diameter of 20mm, compact it with a hollow pressure head with an inner diameter equal to the diameter of the compact mandrel at a pressure of 0.3T, hold the load for 10 seconds, remove the mold and Mandrel, the porous titanium rod or column compacted into green body is sintered under vacuum (vacuum degree is 2×10 -3 Pa), sintering temperature range: 1200°C, sintering time: 6 hours. After sintering, the hollow fiber porous bio-titanium material is obtained, the porosity is 76.6%, and the connectivity of the pore phase is good.

Embodiment 2

[0027] The TA9 titanium alloy fiber with a specification of φ0.08mm is randomly wound on a dense mandrel with a diameter of about 8.0mm, and shaped. Put the mandrel with 20g of titanium alloy fiber wound on the surface into a steel mold with an inner diameter of 20mm, use a hollow indenter with an inner diameter equal to the diameter of the compact mandrel to compact it at a pressure of 0.6T, hold the load for 15 seconds, remove the mold and Mandrel, the porous titanium rod or column compacted into green body is sintered under vacuum (vacuum degree is 2×10 -3 Pa), sintering temperature range: 1250°C, sintering time: 3 hours. After sintering, a hollow fiber porous bio-titanium material is obtained, with a porosity of 47.3%.

Embodiment 3

[0029] The TA0 pure titanium fiber with a specification of φ0.15mm is randomly wound on a dense mandrel with a diameter of about 8.0mm, and shaped. Put the mandrel with 25g of pure titanium fiber wound on the surface into a steel mold with an inner diameter of 20mm, compact it with a hollow pressure head with an inner diameter equal to the diameter of the compact mandrel at a pressure of 0.6T, hold the load for 10 seconds, remove the mold and Mandrel, the porous titanium rod or column compacted into green body is sintered under vacuum (vacuum degree is 2×10 -3Pa), sintering temperature range: 1200°C, sintering time: 2 hours. After sintering, a hollow fiber porous bio-titanium material is obtained, with a porosity of 52.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com