Method for preparing composite microspheres with surface functional group and controllable function

A technology of surface functional groups and composite microspheres, which is applied in the field of nanotechnology preparation, can solve the problem that the fluorescence intensity of fluorescent microspheres cannot be designed according to actual application needs, the intensity of fluorescent microspheres cannot be well controlled, and multiple responses cannot be obtained. Functional microspheres and other problems, to achieve the effect of low cost, wide application range, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

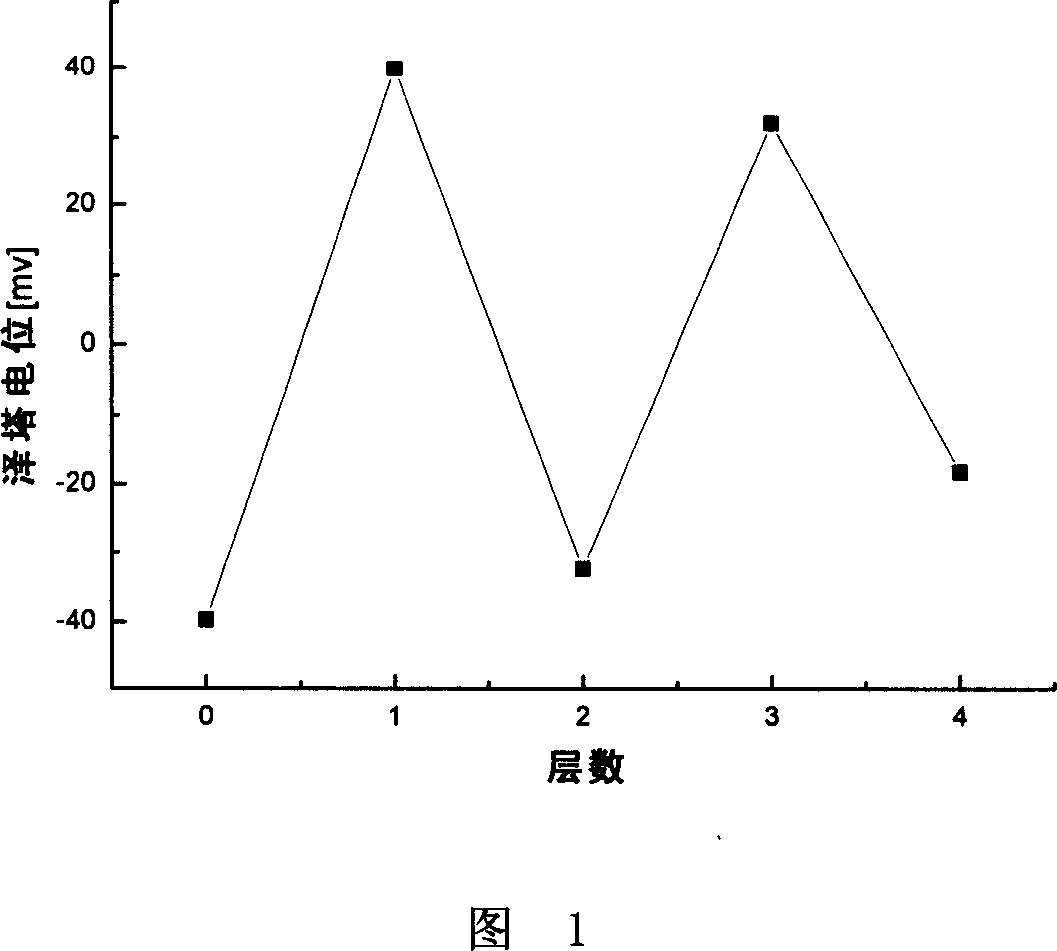

[0021] Take sulfonated polystyrene microsphere aqueous solution, polyallylamine hydrochloride aqueous solution (containing 0.1M NaCl), polystyrene sodium sulfonate aqueous solution (containing 0.1M NaCl) with a concentration of 1.0mg / ml; take 1ml of the above Sulfonated polystyrene microsphere solution, add 5ml of the above-mentioned polyallylamine hydrochloride solution, precipitate and absorb for 10min, centrifuge, then wash the precipitate after centrifugation with pure water for 10 times, and disperse the precipitate in 1ml Form a solution in water, add 5ml of the above-mentioned sodium polystyrene sulfonate solution to the solution, centrifuge after adsorption for 10min, and then wash the precipitate after centrifugation with pure water for 3 times; then add 5ml of polyallylamine The hydrochloride solution is treated according to the above process, so that the surface of the microspheres is sequentially adsorbed with three layers of polyelectrolytes, that is, the outer str...

Embodiment 2

[0023]Prepare sulfonated polymethyl methacrylate microsphere aqueous solution, polydiallyldimethylammonium chloride aqueous solution (containing 0.5M NaCl), polystyrene sodium sulfonate solution (containing 0.5 M NaCl); Take 1ml of the above-mentioned sulfonated polymethyl methacrylate microsphere solution, add 0.5ml of the above-mentioned polydiallyldimethylammonium chloride solution, after precipitation and adsorption for 60min, centrifuge, and then use pure water The solution is cleaned 6 times, and the supernatant is discarded, and the microsphere solution of one deck polyelectrolyte (polydiallyldimethylammonium chloride) is obtained on the surface; then add the above-mentioned sodium polystyrene sulfonate solution of 0.5ml, Centrifuge after 60 minutes of adsorption, wash 6 times, and disperse it in 1ml of water to form two layers of polyelectrolyte (microsphere outer layer structure: polydiallyldimethylammonium chloride / polyphenylene Sodium ethylene sulfonate) microsphere...

Embodiment 3

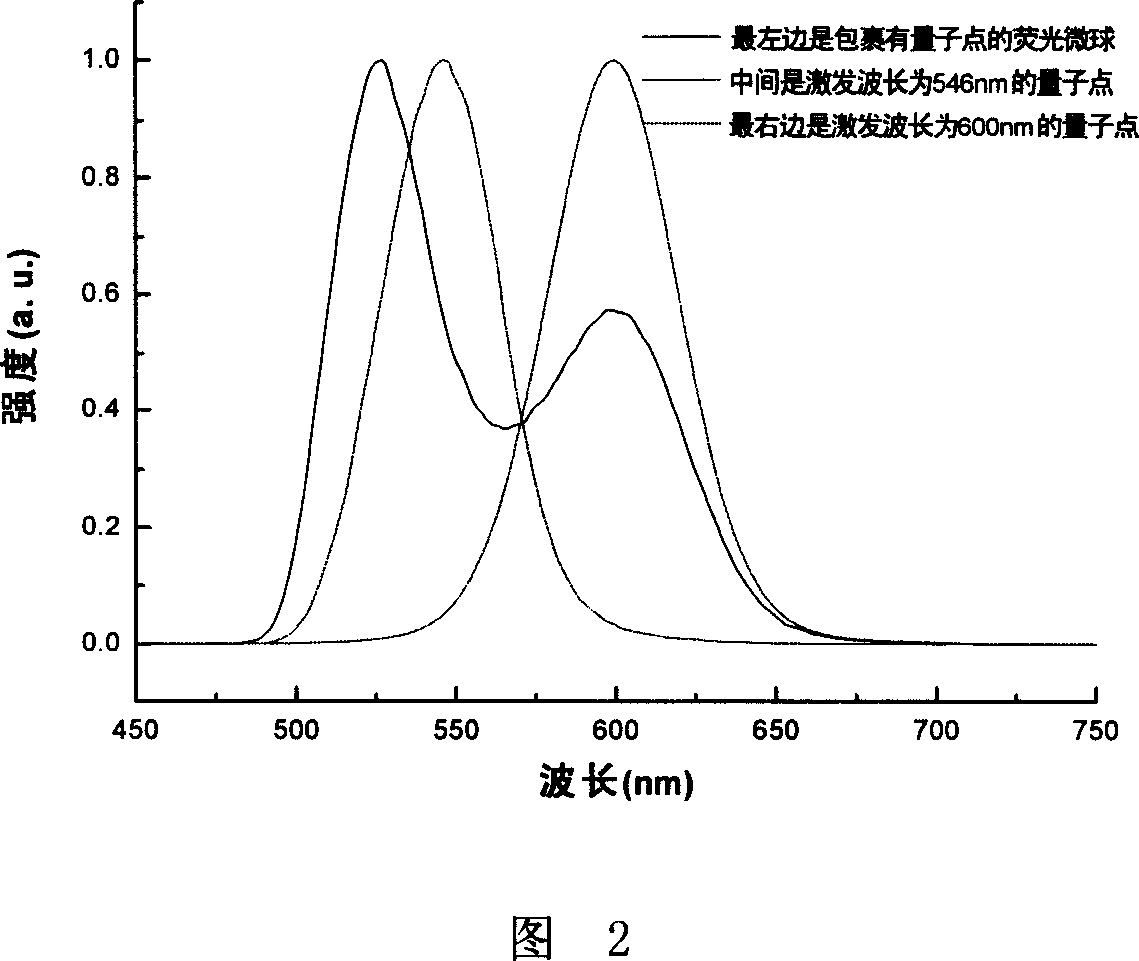

[0025] Take 2.5mg / ml aqueous solution of sulfonated polymethyl methacrylate microspheres, polyallylamine hydrochloride aqueous solution (2.0M NaCl), polystyrene sodium sulfonate solution (2.0M KCl); take 1ml Add 0.5 ml of the above-mentioned polyallylamine hydrochloride solution to the sulfonated polymethyl methacrylate microsphere solution, absorb for 60 minutes, centrifuge, wash the precipitate with pure water for 6 times, and discard the supernatant; Add 100ml of the above-mentioned sodium polystyrene sulfonate solution, centrifuge after adsorption for 60min, wash the precipitate 6 times, and then disperse the precipitate in 1ml of water to obtain two layers of polyelectrolyte (polyallylamine hydrochloric acid) sequentially adsorbed on the surface. Salt / sodium polystyrene sulfonate) sulfonated polymethyl methacrylate microsphere solution; get concentration is 2mmol / L, the surface has the CdTe quantum dot solution 6ml of mercaptoethylamine, add to above-mentioned surface sequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com