Method of preparing sea crystal from byproduct salt of refining iminodiacetic acid

A technology of iminodiacetic acid and by-product salt, which is applied in the fields of alkali metal sulfite/sulfite, chemical instruments and methods, water/sewage treatment, etc., and can solve the problem of affecting the quality of fishery seedlings or cultivation, and the quality of products , environmental pollution and other issues, to achieve the effect of inhibiting the growth of water clouds and weeds, protecting the environment and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

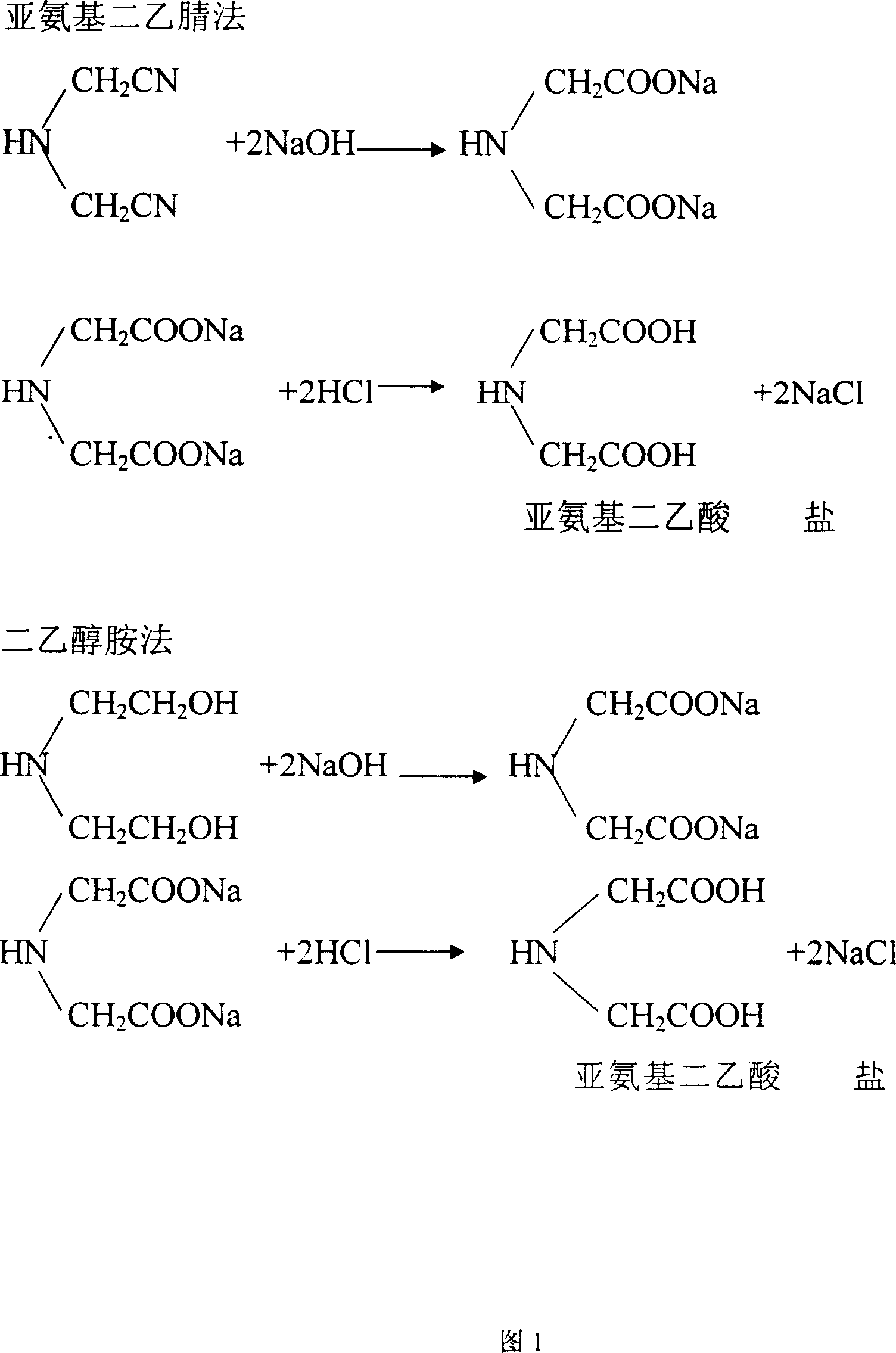

Method used

Image

Examples

Embodiment 1

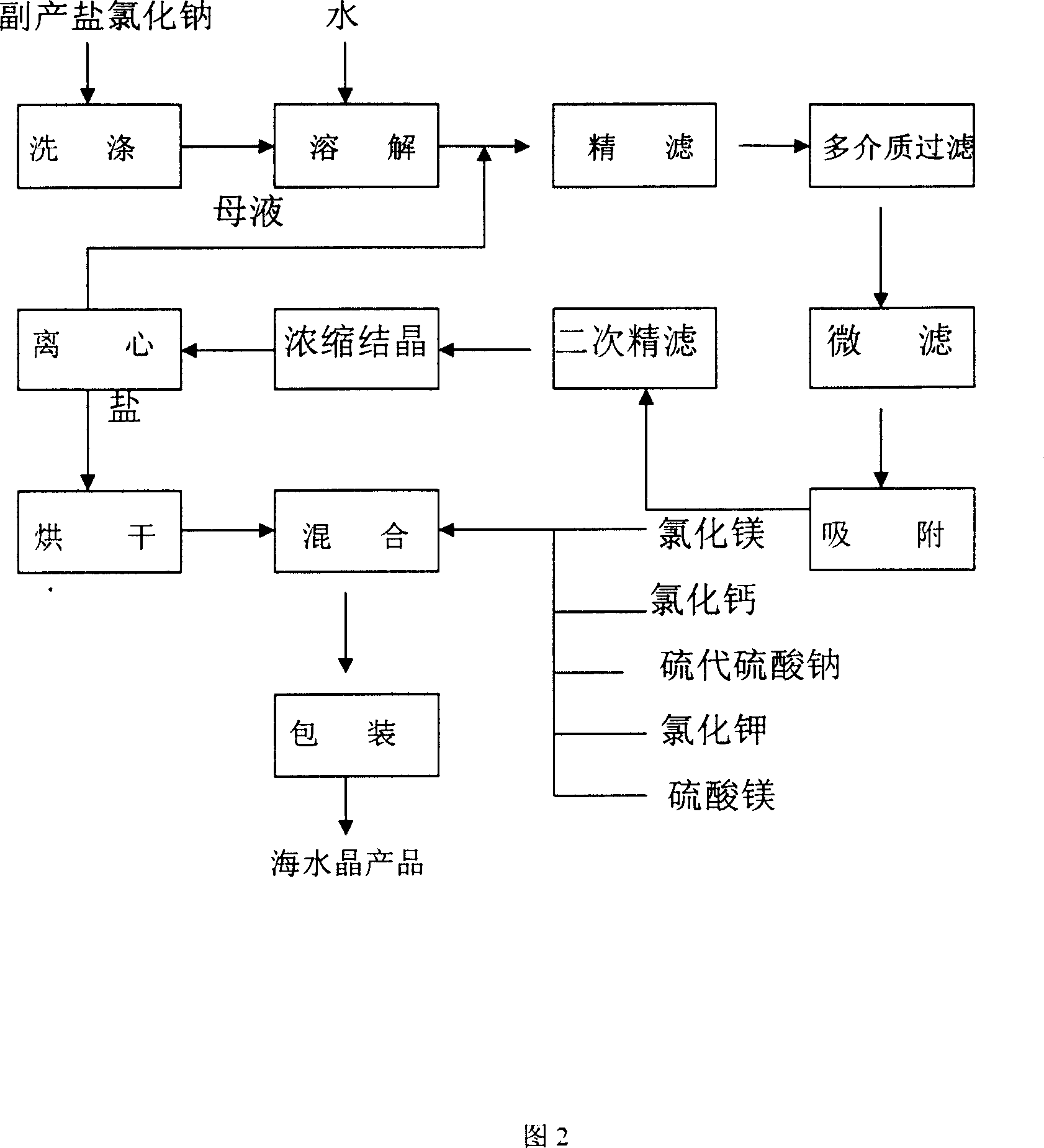

[0034] Embodiment 1: put into 1500kg of iminodiacetic acid sub-salts of the suction filter barrel, drain the mother liquor, add 300kg of water, soak for 30 minutes, and drain; add water 300kg, soak for 30 minutes and drain; the drained salt is dissolved in water, and the solution Continuously pass through a precision filter with a pore size of 20 μm, a multimedia filter with activated carbon, a microporous filter with a pore size of 0.1 μm, an adsorption tower equipped with CR20 polyamide chelating resin, a A precision filter with a pore size of 20 μm is used to remove solid impurities, viscous substances, macromolecular organic matter, heavy metal ions, and damaged resin; the refined solution is concentrated and crystallized, and the mother liquor A and salt obtained are separated, and the obtained salt is passed through Centrifuge, send into airflow dryer, control temperature 100 ℃ and dry continuously, obtain salt content and reach 99%, heavy metal ion content 0.5ppm. Take ...

Embodiment 2

[0035] Embodiment 2: put into 1500kg of iminodiacetic acid sub-salts in the suction filter tank, drain the mother liquor, add 300kg of water, soak for 30 minutes, and drain; add water 300kg, soak for 30 minutes and drain; the drained salt is dissolved in water, add The mother liquor A is mixed evenly, and the mixed solution passes continuously through a precision filter with a pore size of 50 μm, a multimedia filter with activated carbon, a microporous filter membrane with a pore size of 10 μm, and a chelating filter equipped with CR20 polyamide type Resin adsorption tower, a precision filter with a pore size of 50 μm to remove solid impurities, viscous substances, macromolecular organic matter, heavy metal ions and damaged resin; the refined solution is concentrated and crystallized, and the obtained mother liquor B and salt are separated , the obtained salt is centrifuged, placed in a hot air circulation oven, and dried at a controlled temperature of 105°C for 3 hours, the co...

Embodiment 3

[0037] Put 1500kg of iminodiacetic acid sub-salt into the suction filter tank, drain the mother liquor, add 300kg of water, soak for 30 minutes, and drain; add 300kg of water, soak for 30 minutes and drain; the drained salt is dissolved in water, add mother liquor B and mix well , the mixed solution continuously passes through a precision filter with a pore size of 30 μm, a multimedia filter with activated carbon, a microporous filter membrane with a pore size of 1 μm, and an adsorption tower equipped with CR20 polyamide chelating resin 1. A precision filter with a pore size of 25 μm to remove solid impurities, viscous substances, macromolecular organics, heavy metal ions and damaged resins; the refined solution is concentrated and crystallized, and the separated mother liquor set C can continue the refining process The obtained salt is centrifuged and sent to an airflow dryer, and the temperature is controlled at 130°C for continuous drying to obtain a salt content of 99% and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com