Method of preparing anode catalysis electrode for preparing hydrogen by electrolyzing coal slurry

A catalytic electrode and anode technology, applied in the field of electrochemical deposition technology, can solve the problems of low electrocatalytic activity, reduce the service life of electrodes, corrosion of titanium substrate, etc., and achieve the effect of increasing specific surface area, improving catalytic activity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

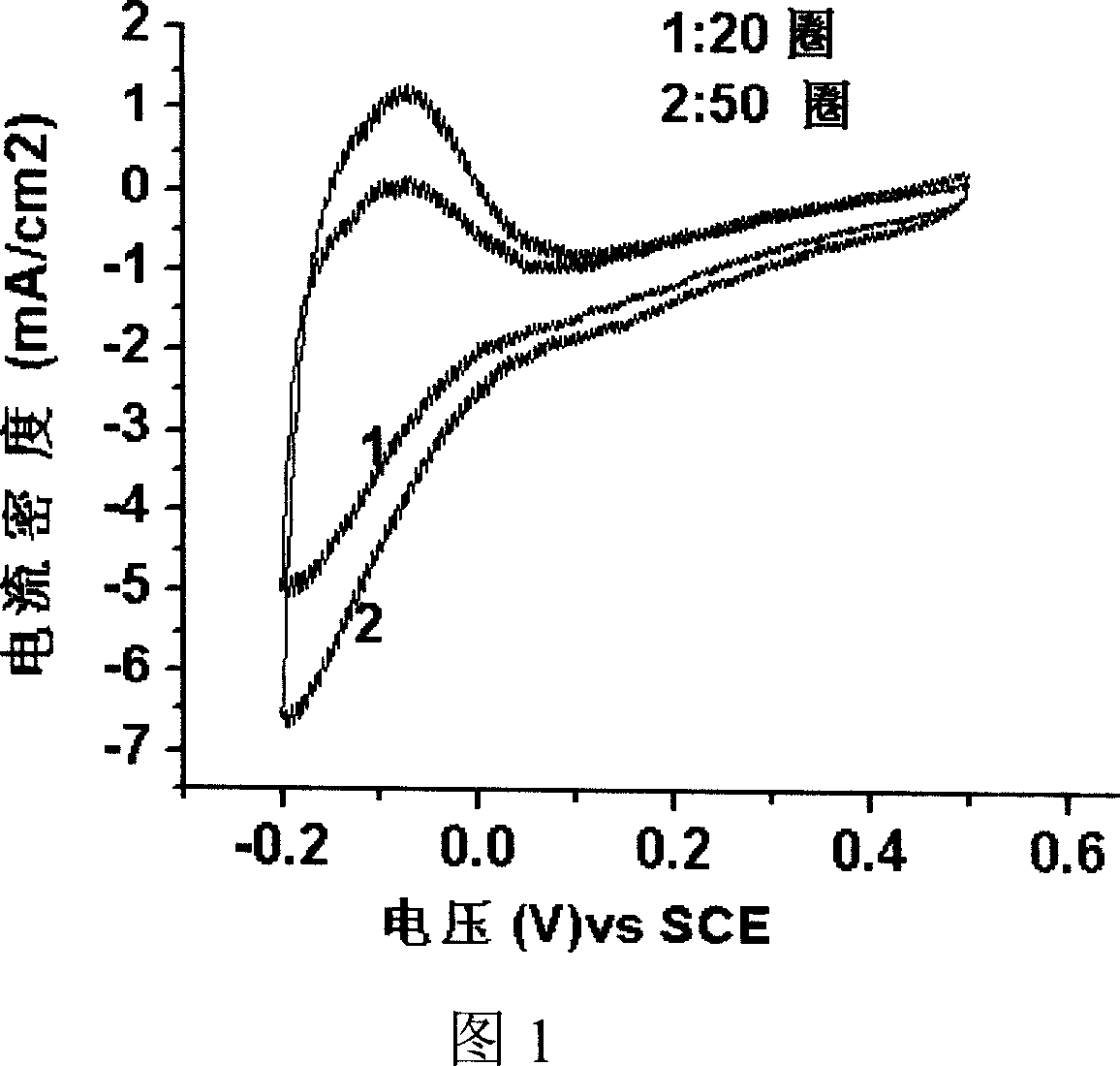

[0025] This example is Ti / TiO 2 - Preparation of Pt anode catalytic electrode. Its preparation steps are as follows:

[0026] (1) Pretreatment of the metal titanium substrate: firstly, the metal titanium substrate is polished and polished, then placed in acetone for ultrasonic degreasing for 5 minutes, then ultrasonically cleaned with twice distilled water, and then treated with a certain concentration of hydrofluoric acid for 1 minute , then rinsed with hot double distilled water, and dried for later use.

[0027] (2) Layered porous TiO on titanium-based surface 2 Preparation of thin film: put the above pretreated titanium substrate in an electrolytic cell, oxidize it in a sulfuric acid electrolyte with a concentration of 1mol / L for 5 minutes, control a certain potential, that is, a DC voltage of 120V, and finally obtain a layered porous TiO 2 Film, this is the prepared state oxide film;

[0028] (3) Treat the above prepared oxide film with low concentration (5%) HF for 1...

Embodiment 2

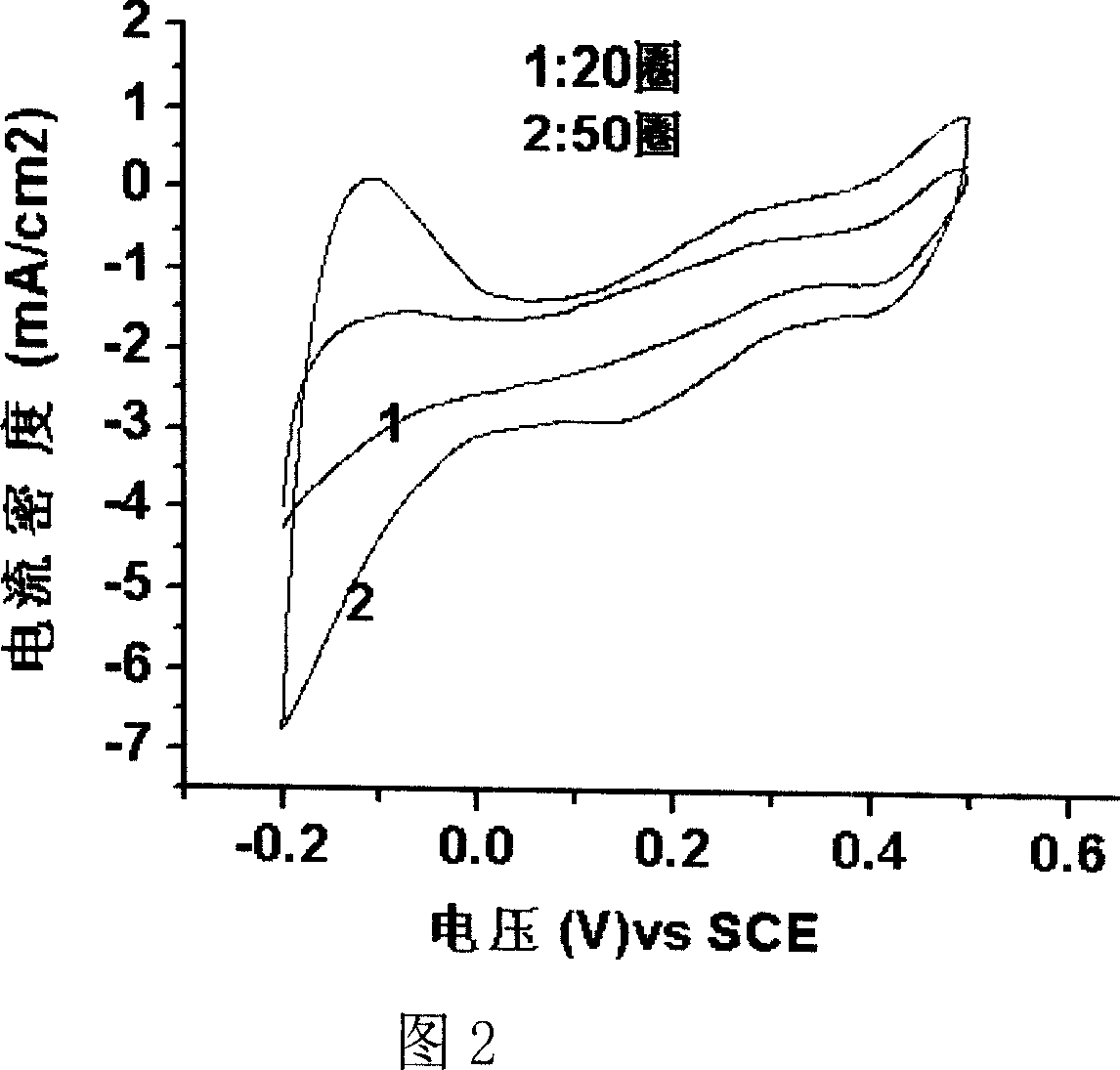

[0032] This example is Ti / TiO 2 -Preparation of the Pt-Ru anode catalytic electrode, wherein the molar ratio of Pt and Ru in the plating solution is 1:2, and the preparation steps are the same as before.

[0033] The preparation steps of this embodiment are exactly the same as those of the above-mentioned embodiment 1. The difference is in (4) step: before plating, the catalyst solution is a concentration of 5 × 10 -3 mol / L of H 2 PtCl 6 6H 2 O and 1×10 -2 mol / L RuCl 3 mixture.

[0034] TiO in this example 2 The cyclic voltammetry curve of surface deposited Pt-Ru (molar ratio Pt:Ru=1:2) is shown in Figure 2

Embodiment 3

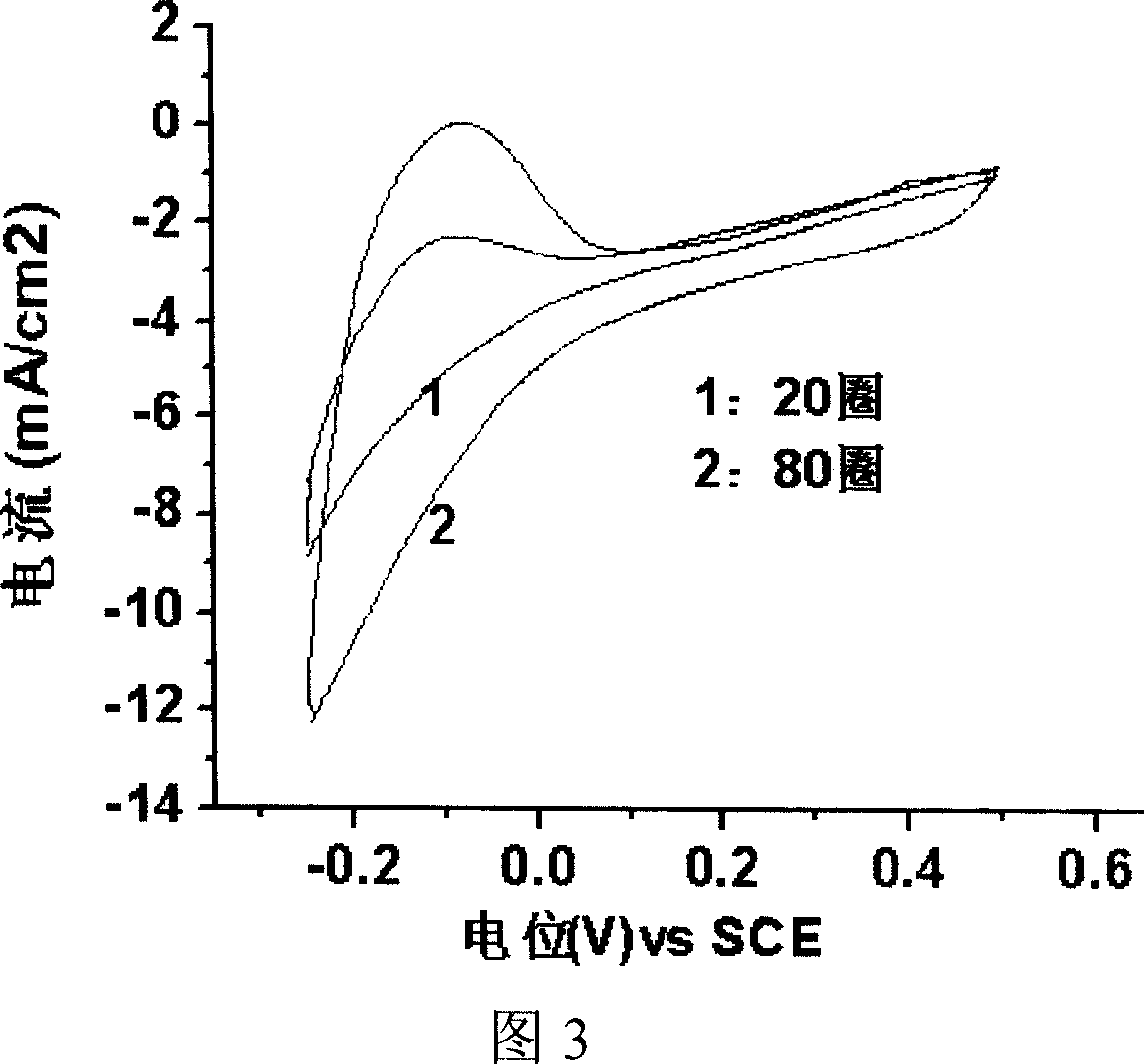

[0036] This example is Ti / TiO 2 -Preparation of the Pt-Ir anode catalytic electrode, wherein the molar ratio of Pt and Ir in the plating solution is 1:2, and the preparation steps are the same as before.

[0037] The preparation steps of this embodiment are exactly the same as those of the above-mentioned embodiment 1. The difference is in (4) step: before plating, the catalyst solution is a concentration of 5 × 10 -3 mol / L of H 2 PtCl 6 6H 2 O and 1×10 -2 mol / L of IrCl 3 mixture.

[0038] TiO in this example 2 The cyclic voltammetry curve of surface deposited Pt-Ir (molar ratio Pt:Ir=1:2) is shown in Figure 3

[0039] A comparative test between the anode catalytic electrode prepared in the embodiment of the present invention and other different electrodes; test the I-V curves of different electrodes in the process of electrolyzing coal slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com