Method for preparing theanine

A technology of theanine and catechin, applied in the field of biochemistry, can solve the problems of unsuitable industrial production and the like, and achieve the effects of easy industrial production, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

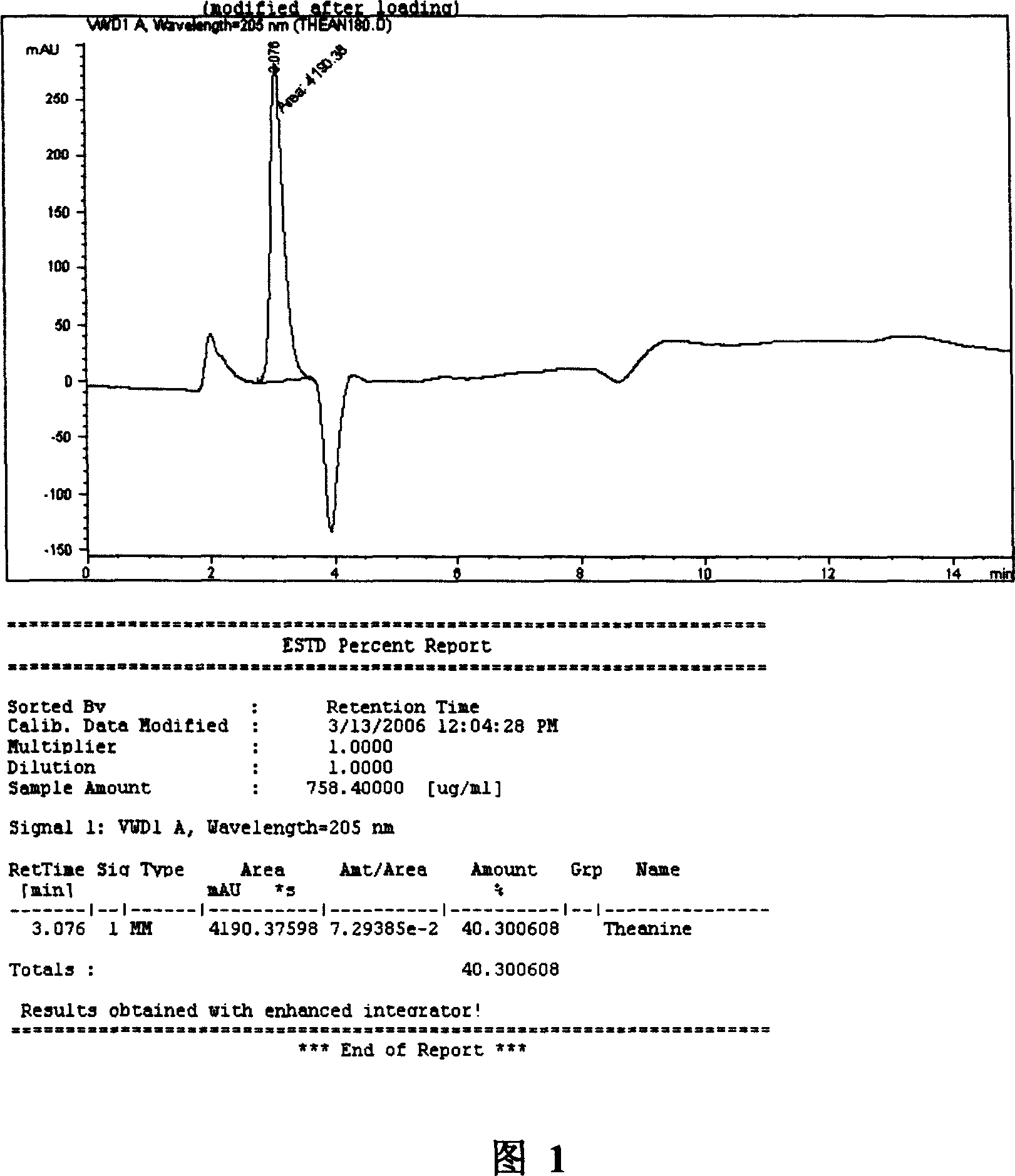

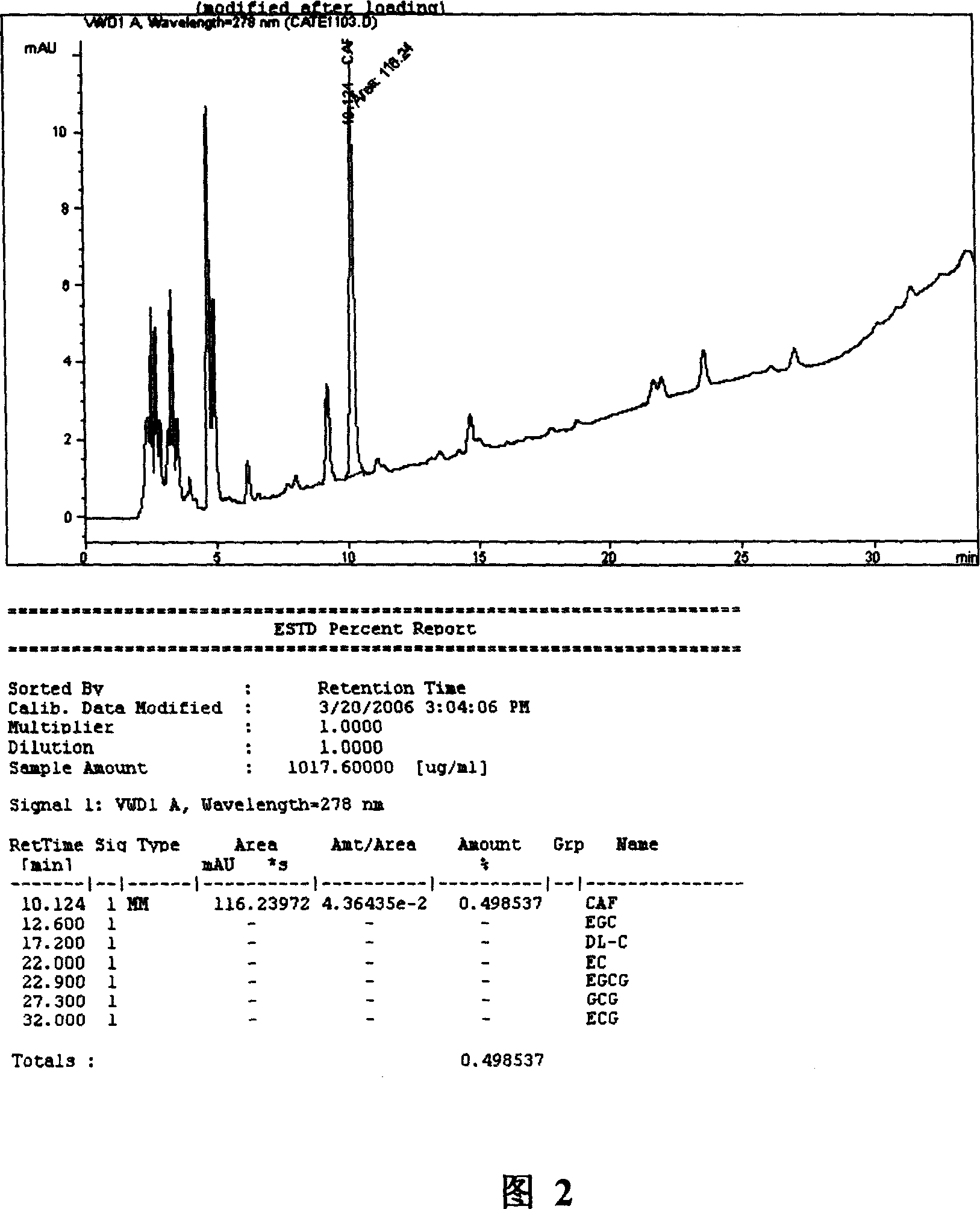

Embodiment 1

[0018] Weigh 30kg of tea raw materials, the content of theanine in the tea leaves is 1.5%, add 5 times the amount of pure water (150 liters), heat to 70°C, extract for 0.5 hours, then extract twice under the same conditions, and combine the extracts to 351.7kg , through disc centrifugation and tube centrifugation, and then use 1000D ultrafiltration membrane to remove polyphenols, polysaccharides, colloids, pigments and other substances to obtain 400 kg of processed feed liquid, which is adjusted to pH=1 with 36% hydrochloric acid and passed through For the column equipped with ZB-1 strong cation exchange fiber, control the flow rate of the passing liquid to 2BV / h. After the column is loaded, use 60 liters of pure water to drive out the residual liquid in the column, and then use 3% sodium carbonate solution Analyze, collect the analytical solution containing theanine, concentrate to 2 liters and add 95% ethanol for precipitation, filter the filtrate to concentrate in vacuo and ...

example 2

[0020] Weigh 30kg of tea raw material, the content of theanine in the tea leaves is 1.5%, add 8 times the amount of pure water (240 liters) for the first time, heat to 80°C, extract for 0.5 hours, add 7 times the amount (140 liters) for the second time Extract 0.5 / h with pure water at 80°C, combine 359.5kg of extracts, first filter with 0.1μ microfiltration membrane, and then use 10000D ultrafiltration and 500D nanofiltration to remove polyphenols, polysaccharides, colloids, pigments and other substances , 415 kg of the processed feed liquid was obtained, and the feed liquid was carefully adjusted to pH 3 with 36% hydrochloric acid, and the column with ZB-1 strong cation exchange fiber was installed on it, and the flow rate of the liquid passed through was controlled to be 2BV / h. Purified water was used to drive out the column residual liquid in the column, and then analyzed with 2% sodium hydroxide solution, and the analytical solution containing theanine was collected, and th...

example 3

[0022] Weigh 30kg of tea raw materials, the content of theanine in the tea leaves is 1.5%, add 10 times the amount of pure water (300 liters) for the first time, heat to 90 °C, extract for 0.5 hours, add 8 times the amount (240 liters) for the second time 90□Pure water extraction 0.5 / h, combined extract 451.9kg, first use 200-mesh nylon cloth to remove leaf residue, then use 0.2μ microfiltration membrane for primary filtration, and then use 20000D ultrafiltration membrane to remove polyphenols, polysaccharides and colloids , pigments and other substances, to obtain 489.5kg of the processed feed liquid, the feed liquid was carefully adjusted to pH=3 with 36% hydrochloric acid, and the column equipped with ZB-1 cation exchange fiber was installed, and the flow rate of the liquid passed through was controlled to be 2BV / h. , use 90 liters of 50% ethanol to drive out the column residue in the column, then analyze with 1% ammonia solution, collect the analysis solution with theanine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com