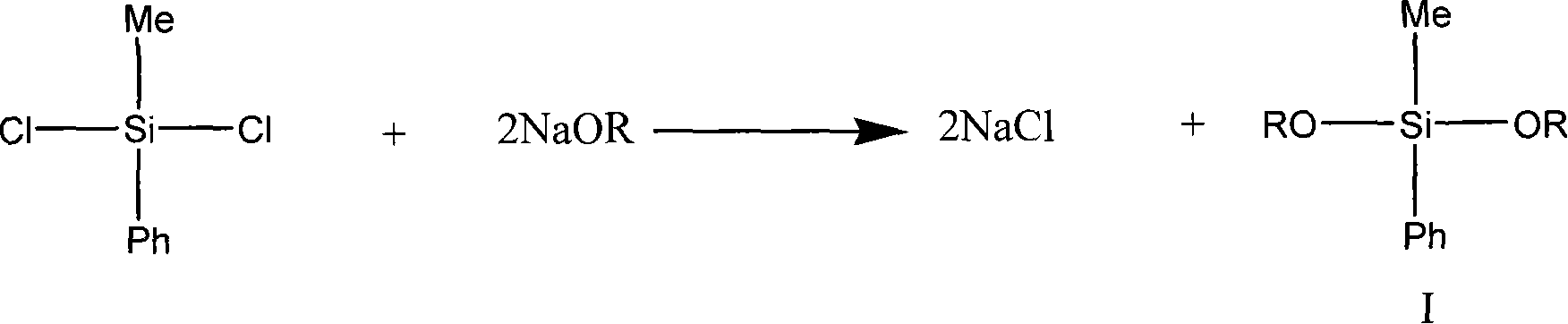

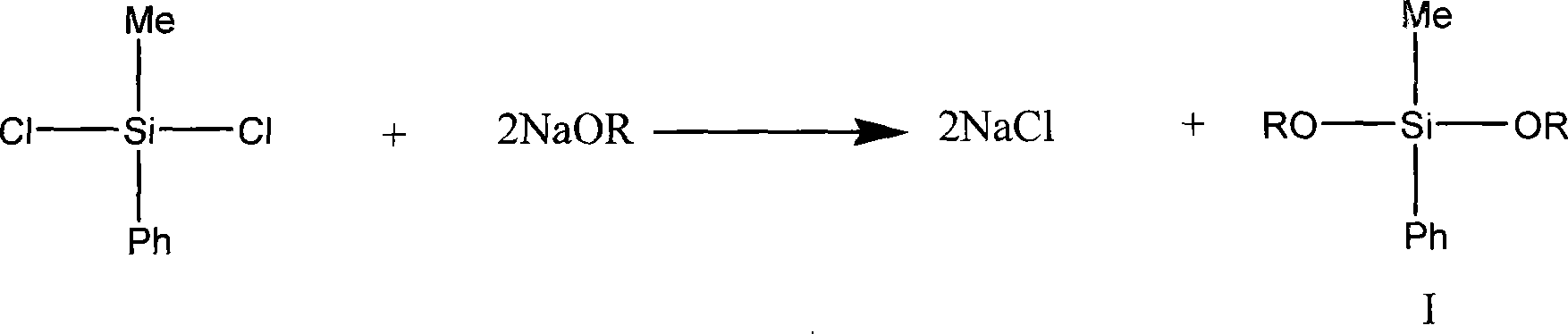

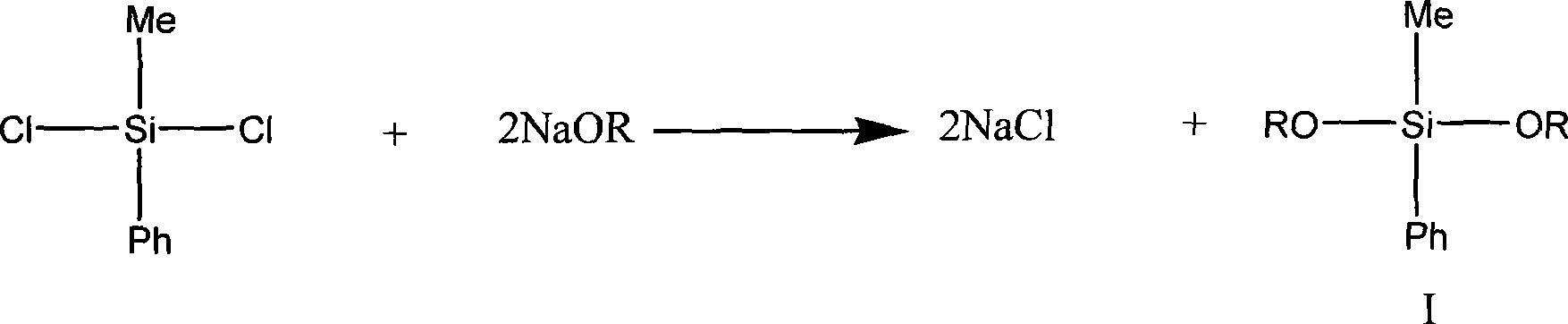

Safe separation method for increasing yield of methyl phenyl dialkoxy silicane

A technology of methylphenyldialkoxysilane and methylphenyldichlorosilane, which is applied in the field of organosilicon chemistry, can solve the problems of heavy separation load, high separation cost, and difficult separation and purification, so as to increase yield, The effect of high yield, safe and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The 1000mL three-necked flask equipped with a constant-pressure pressurized funnel, a stirrer and a pH meter was placed in a cold water bath with a temperature of 10.4° C. Under nitrogen protection, the solid content of 564.5g of sodium condensation synthesis was added to the three-necked flask and was 30 %, the methylphenylethoxysilane conversion material with a methylphenyldiethoxysilane content of 13.54%, start stirring, and pass 103.2g of methylphenyldichlorosilane with a concentration of 98.2% within 0.5h. The constant pressure feeding funnel was slowly added dropwise into the three-necked flask. After the dropwise addition of methylphenyldichlorosilane, the temperature of the mixed solution in the three-necked flask was 17.1°C, and the pH value of the mixed solution was 6.9. The mixture obtained by titration was filtered under reduced pressure to obtain 383.9 g of clear filtrate. After GC analysis, its mass composition was 40.92% of toluene, 2.78% of chlorobenzene,...

Embodiment 2

[0031]A 1000mL three-necked flask equipped with a constant-pressure pressurized funnel, a stirrer and a pH meter is placed in a cold water bath with a temperature of 8.6°C, and under a dry air atmosphere, the solid content of adding 560.6g of sodium condensation to the three-necked flask is: 30% methylphenylethoxysilane conversion material with a methylphenyldiethoxysilane content of 13.54%, start stirring, and pass 101.9 g of methylphenyldichlorosilane with a concentration of 90.7% through it within 1 hour. The constant pressure feeding funnel was slowly added dropwise into the three-necked flask. After the dropwise addition of methylphenyldichlorosilane was completed, the temperature of the mixed solution in the three-necked flask was 18.7°C, and the pH value of the mixed solution was 6.6. The mixture obtained by titration was filtered under reduced pressure to obtain 289.7g of clear filtrate. After GC analysis, its mass composition was toluene 41.66%, chlorobenzene 2.84%, me...

Embodiment 3

[0034] The 1000mL three-necked flask equipped with a constant-pressure pressurized funnel, a stirrer and a pH meter was placed in a cold water bath with a temperature of 6.4° C. Under a nitrogen atmosphere, the solid content of adding 570.2g of sodium condensation to the three-necked flask was 32. %, methylphenyldimethoxysilane conversion material with a methylphenyldimethoxysilane content of 17.3%, start stirring, and pass 108.0 g of methylphenyldichlorosilane with a concentration of 95.3% through it within 1.5h. The constant pressure feeding funnel was slowly added dropwise into the three-necked flask. After the dropwise addition of methylphenyldichlorosilane, the temperature of the mixed solution in the three-necked flask was 18.9°C, and the pH value of the mixed solution was 7.0. The mixture obtained by titration was filtered under reduced pressure to obtain 303.5 g of clear filtrate. After GC analysis, its mass composition was 40.32% of toluene, 2.76% of chlorobenzene, 39....

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com