Photo-sensitive resin composition containing inorganic particle, photo-sensitive film, and process of forming inorganic pattern

A resin composition, inorganic particle technology, applied in photosensitive materials for optomechanical equipment, microlithography exposure equipment, optics, etc., can solve the problem of poor thermal decomposition of photosensitive compositions, large shrinkage, screen printing Incompatibility and other problems, to achieve the effect of excellent thermal decomposition and less shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0205] Hereinafter, although this invention is demonstrated more concretely based on an Example, this invention is not limited at all by these Examples.

[0206] First, the measurement methods of the weight average molecular weight (Mw), the measurement method of the glass transition temperature, the weight loss analysis, the evaluation of the pattern after development, and the evaluation of the pattern after firing will be described. In addition, the density|concentration (%) in an Example and a comparative example is "weight%" unless otherwise indicated, and "part" means a "weight part".

[0207] (Measurement method of weight average molecular weight (Mw))

[0208] Mw is the polystyrene-equivalent weight average molecular weight measured by gel permeation chromatography (GPC) ("HLC-8220GPC" by Tosoh Corporation). In addition, the GPC measurement was carried out using "TSK guardcolumn SuperHZM-M" manufactured by Tosoh Corporation as a GPC column, using THF (tetrahydrofuran) ...

Synthetic example 1

[0218] Methyl methacrylate (MMA), benzyl methacrylate (BzMA), 2-hydroxyethyl methacrylate (HEMA), methacrylic acid (MAA), azobisisobutyronitrile (AIBN) as The weight ratios shown in Table 1 were metered and mixed, and the resulting solution was put into an autoclave equipped with a stirrer, and stirred in 150 parts of propylene glycol monomethyl ether (PGME) until uniform under a nitrogen atmosphere. Then, after superposition|polymerization was carried out at 80 degreeC for 4 hours, and further 1 hour of polymerization reaction was continued at 100 degreeC, it cooled to room temperature, and alkali-soluble resin (A1) was obtained. Table 2 shows the yield, weight average molecular weight, glass transition temperature, temperature of 10% weight loss rate and weight loss rate of 450° C. of the alkali-soluble resin (A1).

Synthetic example 2

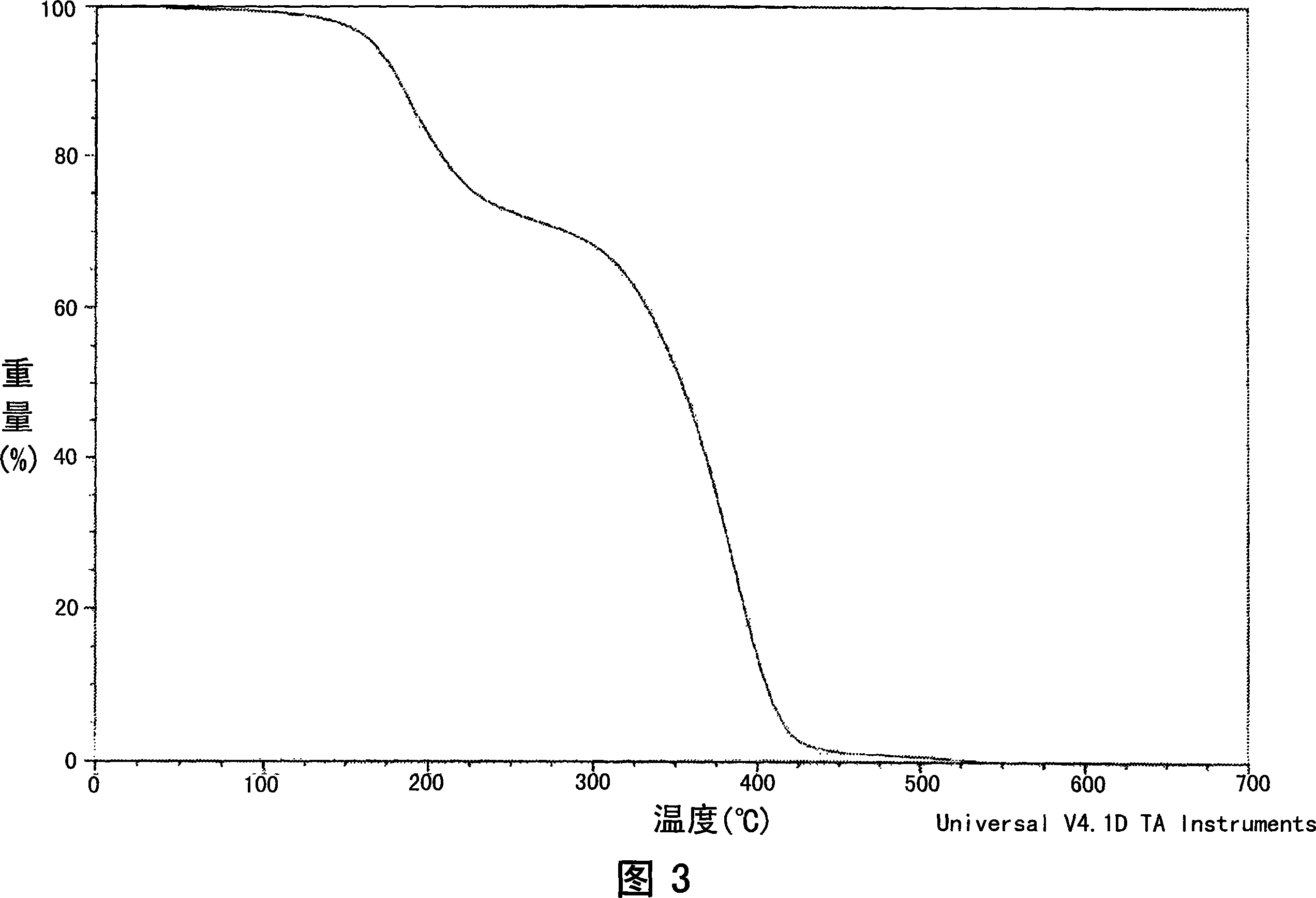

[0220] Except having changed the ratio of an acrylic monomer as shown in Table 1, it reacted similarly to the synthesis example 1, and obtained alkali-soluble resin (A2). Table 2 shows the yield, weight-average molecular weight, glass transition temperature, temperature of 10% weight loss rate and weight loss rate of 450° C. of the obtained alkali-soluble resin (A2). In addition, the weight loss analysis graph of the alkali-soluble resin (A2) is shown in FIG. 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com