Method for preparing oxalic acid decarboxylase by fungus

A technology of oxalate decarboxylase and fungi, applied in the direction of lyase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of acid solution

[0028] The liquid acid can be made into a concentrated solution by pipetting the corresponding amount, and the solid acid can be made into a corresponding concentrated solution by weighing a certain amount of powder with deionized water. The concentration is generally about 1mol / L to 2mol / L. The oxalic acid solution was prepared with an ion concentration of 0.5M. The prepared acid solution was sterilized at 121°C for 20 minutes or sterilized by filtration before use.

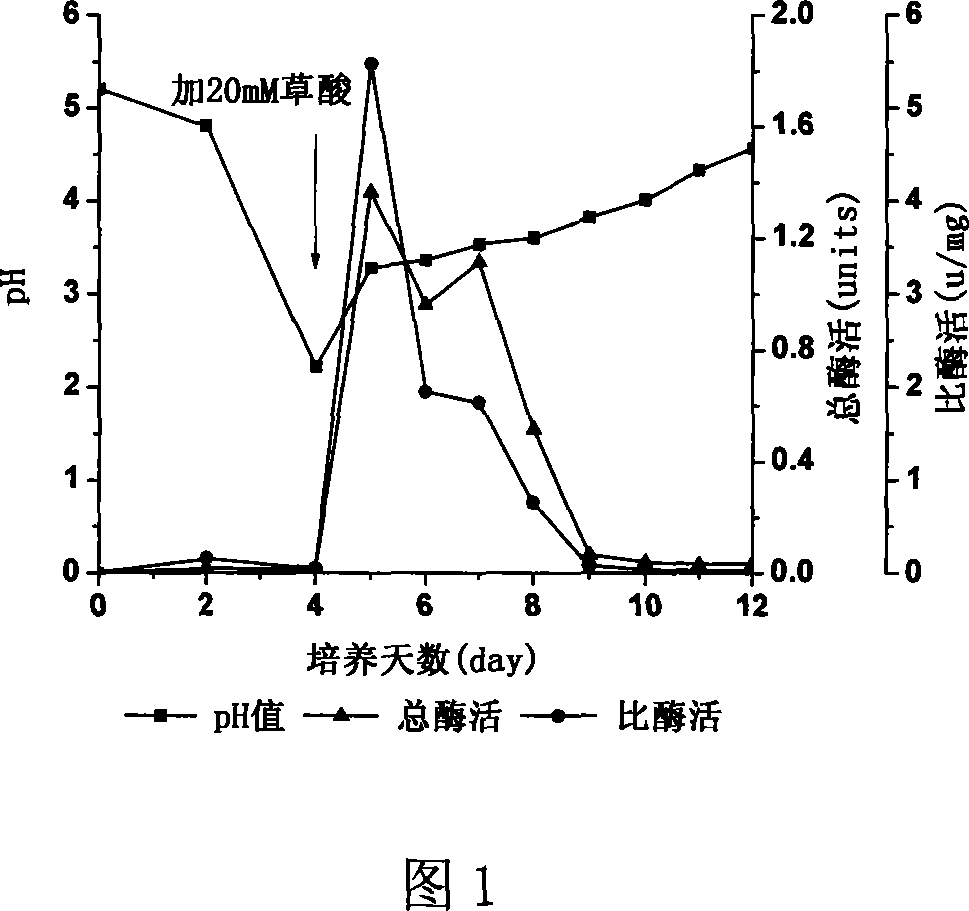

[0029] 2. The amount and timing of acid addition

[0030] On the third or fourth day of bacterial growth, that is, when the growth is about to enter the logarithmic growth phase, the inducer is added. The amount of oxalic acid or oxalate added is such that the final oxalate ion concentration in the medium is 3-40 mmol / L. Other acids were added in such amounts that the pH of the culture medium dropped below 3.0.

[0031] 3. Trametes versicolor PRL 572 produces oxalate ...

Embodiment 2

[0047] 1. Preparation of acid solution

[0048] The liquid acid can be made into a concentrated solution by pipetting the corresponding amount, and the solid acid can be made into a corresponding concentrated solution by weighing a certain amount of powder with deionized water. The concentration is generally about 1mol / L to 2mol / L. The oxalic acid solution was prepared with an ion concentration of 0.5M. The prepared acid solution was sterilized at 121°C for 20 minutes or sterilized by filtration before use.

[0049] 2. The amount and timing of acid addition

[0050] On the third or fourth day of bacterial growth, that is, when the growth is about to enter the logarithmic growth phase, the inducer is added. The amount of oxalic acid added is such that the final concentration of oxalate ions in the medium is 5-40 mmol / L. Other acids were added in such amounts that the pH of the culture medium dropped below 3.0.

[0051] 3. Aspergillus niger (Aspergillus niger) ATCC 46890 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com