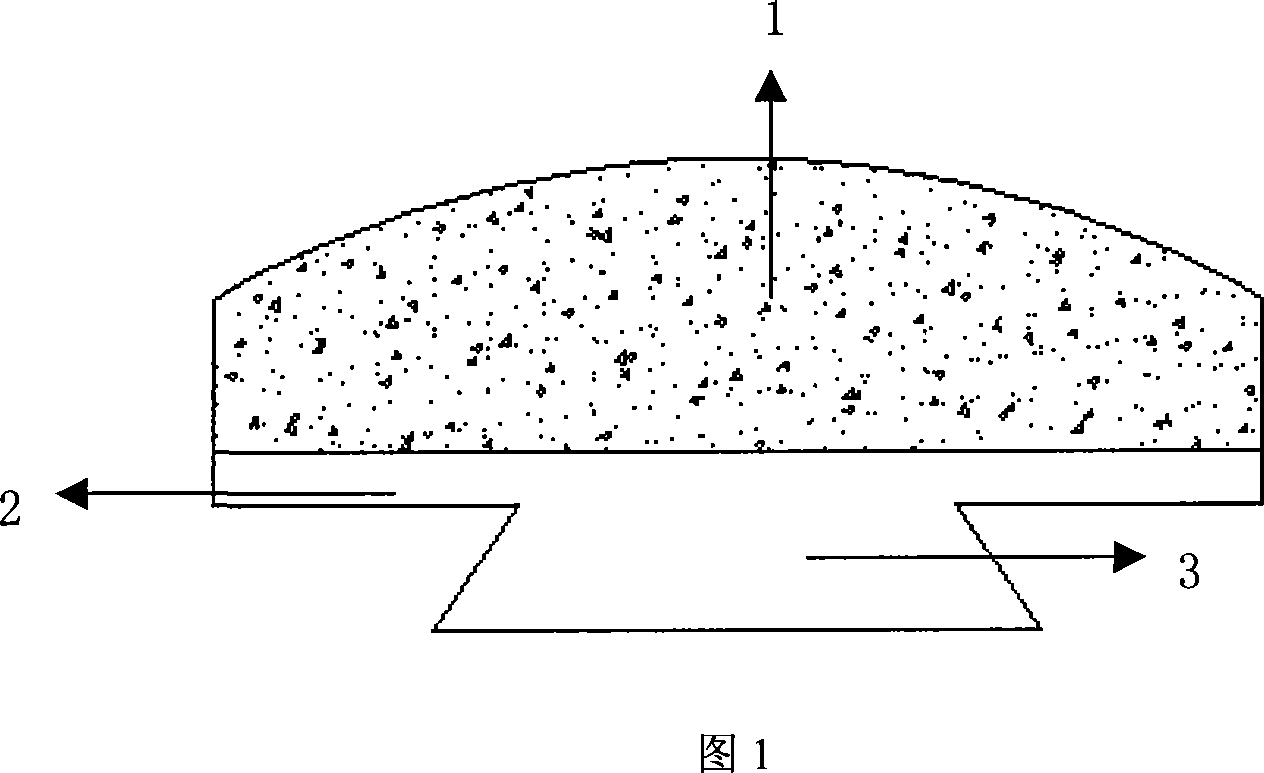

Polishing diamond block with metal binder and its making process

A metal bond, diamond technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of complex diamond polishing blocks, many wastes, long production cycle, etc., to achieve easy product quality assurance , The preparation process is simple and the effect of reducing the number of replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Binder composition: Al: 37% Cu: 21% Ag: 13%

[0025] Ti: 10% Zn: 10% Mg: 4%

[0026] Other materials 5%

[0027] Transition layer composition: Al: 80% Cu: 20%

[0028] Mounting part: Al: 80% Cu: 20%

[0029] Diamond: particle size 140 / 170, concentration 60%

[0030] Its preparation method is: according to the above-mentioned binder composition and diamond polishing block specifications, weigh the corresponding powder respectively, add the required concentration of diamond, add an appropriate amount of paraffin, fully mix it on the mixer for 24 hours, and set it aside; put the transition layer and the card Part of the powder is mixed evenly in proportion and set aside.

[0031] Put 1000g of uniformly mixed powder into the bottom layer of the mold and spread it; add 200g of transition layer powder and spread it; add 300g of powder for the clamping part and spread it; put it into an atmosphere-protected sintering furnace for hot pressing and...

Embodiment 2

[0034] Binder composition: Al: 30% Mg: 37% Ti: 10%

[0035] Zn: 10% Cu: 10%

[0036] 3% for other materials

[0037] Transition layer composition: Al: 80% Mg: 20%

[0038] Mounting part: Al: 80% Cu: 20%

[0039] Diamond: particle size 140 / 170, concentration 60%

[0040] Weigh the corresponding powder according to the above-mentioned binder composition and diamond polishing block specifications, add the required concentration of diamond, add an appropriate amount of paraffin, fully mix it on the mixer for 24 hours, and set it aside; Mix well and set aside.

[0041] Put 600g of uniformly mixed powder into the bottom layer of the mold and spread it; add 155g of transition layer powder and spread it; add 300g of powder for the clamping part and spread it; put it into a cold press to form under a pressure of 150MPa, demould, and sinter Pressureless sintering in the furnace, the sintering temperature is 650°C, and the temperature is kept for 60 minut...

Embodiment 3

[0043] Binder composition: Al: 50% Si: 17% Ti: 10%

[0044] Sn: 10% Cu: 10%

[0045] 3% for other materials

[0046] Transition layer composition: Al: 80% Mg: 20%

[0047] Mounting part: LY12 alloy

[0048] Diamond: particle size 100 / 120, concentration 35%

[0049] Weigh the corresponding powder according to the above-mentioned binder composition and diamond polishing block specifications, add the required concentration of diamond, add an appropriate amount of paraffin, fully mix on the mixer for 24 hours, and set aside; mix the transition layer powder in proportion, and set aside .

[0050] Put 600g of uniformly mixed powder into the bottom layer of the mold with raised ribs and spread it; add 155g of transition layer powder and spread it; add the processed LY12 alloy clamping part; put it into a press and press it under 15MPa pressure Sintering, the sintering temperature is 650°C, and the temperature is kept for 60 minutes. After the sintering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com