Preparation process of nanometer RE oxide particle

A technology of rare earth fluorides and nanoparticles, applied in the fields of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

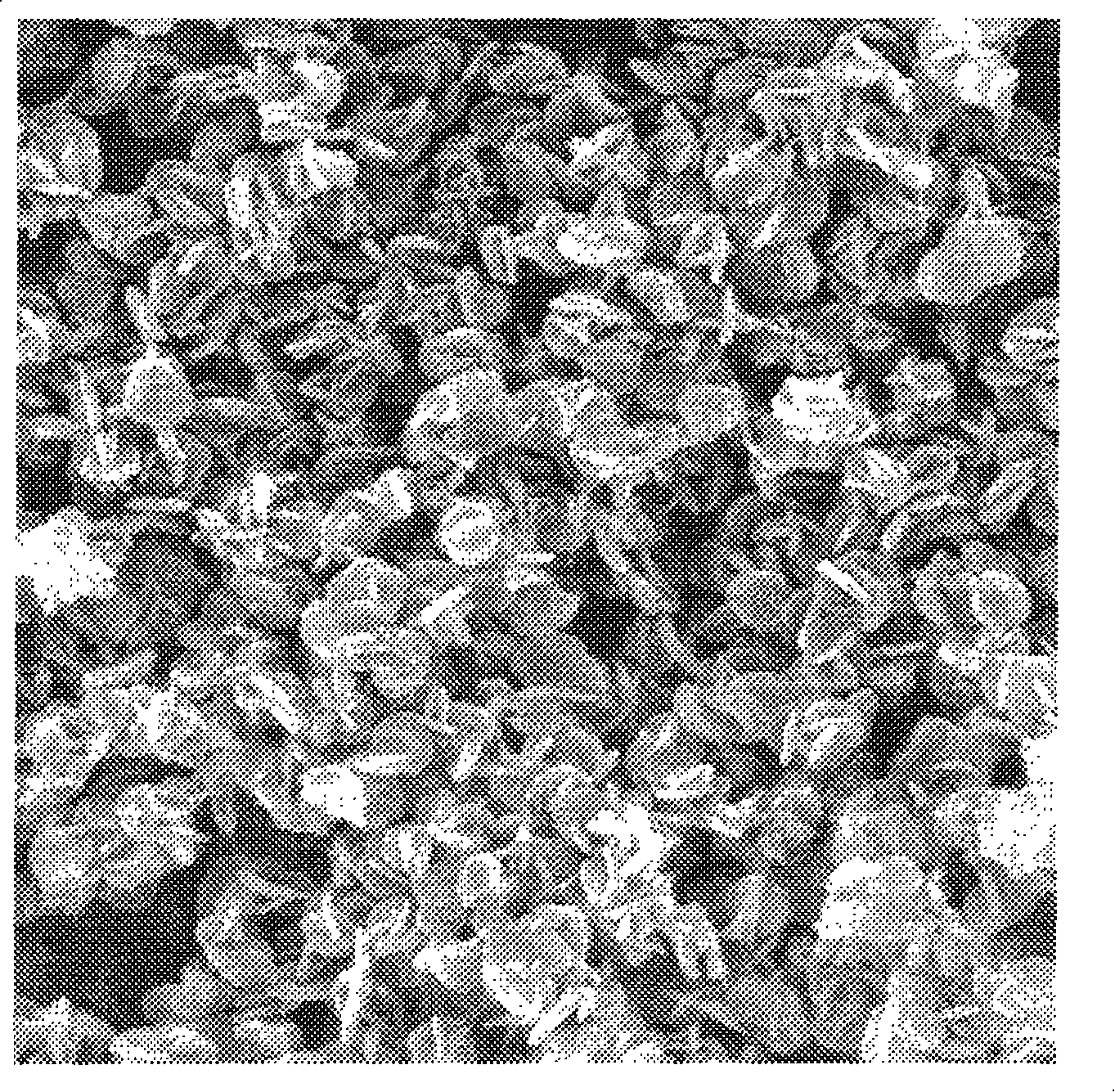

[0024] Take 1mL of 0.3g / mL cerium nitrate ethanol solution, add it to 10mL 1-octyl-3-methyl-hexafluorophosphate, stir the mixture evenly, then add it into a 18mL stainless steel pressure-resistant reactor, After reacting at ℃ for 10 hours, the reaction solution was diluted with 3 times the volume of the reaction solution in absolute ethanol, the product was centrifuged, washed with absolute ethanol, and dried to obtain a rare earth fluoride nanoparticle. The XRD pattern confirms the product

[0025] For cerium trifluoride. The product obtained by SEM observation is disc-like nanoparticles with uniform size, about 200 nanometers in diameter and about 20 nanometers in thickness.

Embodiment 2

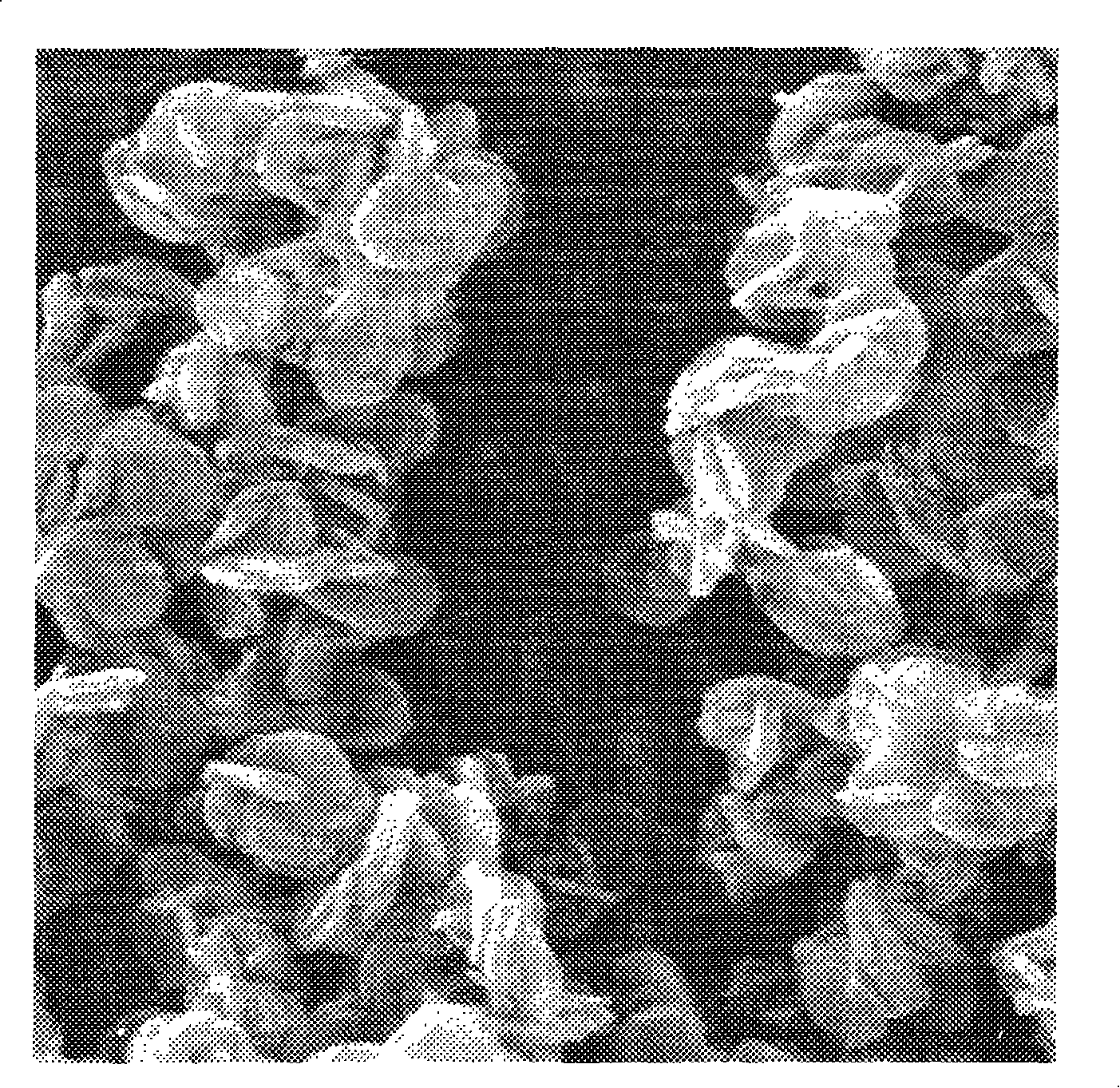

[0027] Take 3mL of 0.02g / mL ethanol solution of lanthanum nitrate, add it to 15mL 1-hexyl-3-methyl-hexafluorophosphate, stir the mixture evenly, then add it to a 18mL stainless steel pressure-resistant reaction kettle, After reacting for 12 hours, dilute the reaction solution with 3 times the volume of the reaction solution in absolute ethanol, centrifuge to separate the product, wash with absolute ethanol, and dry to obtain a rare earth fluoride nanoparticle. The XRD pattern confirmed that the product was lanthanum trifluoride. The product observed by SEM is a disk-shaped particle with a diameter of about 50-100 nanometers and a thickness of about 10 nanometers.

Embodiment 3

[0029] Take 2mL of 0.1g / mL praseodymium nitrate ethanol solution, add it to 10mL 1-butyl-3-methyl-hexafluorophosphate, stir the mixture evenly, then add it into a 18mL stainless steel pressure-resistant reaction kettle, at 50 After reacting at ℃ for 10 hours, the reaction solution was diluted with 3 times the volume of the reaction solution in absolute ethanol, the product was centrifuged, washed with absolute ethanol, and dried to obtain a rare earth fluoride nanoparticle. The XRD spectrum confirmed that the product was praseodymium trifluoride. The product observed by SEM is a disc-shaped particle with a diameter of about 150 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com