Photon crystal formboard preparing method under dynamic physical limiting conditions

A limited condition, photonic crystal technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as difficulty, photonic crystal or photonic crystal template falling off, etc., achieve low cost, reduce defects, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The PS microspheres are evenly dispersed in a mixture of deionized water and absolute ethanol with a volume ratio of 2:3 until a milky white uniformly diluted suspension is formed, and placed in a bottle for later use.

[0019] Cut the ITO glass into 10×30mm, soak it in NaOH saturated ethanol solution, and ultrasonically clean it with deionized water and cleaning solution, then rinse it with deionized water, and put it in deionized water for use. The conductive surfaces of the two pieces of ITO glass are facing each other, and 8um polyethylene films are placed on the left and right edges, then bonded with glue, fixed with clips, and the simple device is placed at 30°. The ITO glass used in the experiment has good wettability with the water-based suspension of PS microspheres. With the help of capillary force, the diluted suspension fills the entire gap of the ITO glass, forming a three-dimensional mixture of ITO glass / diluted suspension / ITO glass. layer structure. Star...

Embodiment 2

[0021] The procedure is similar to Example 1, except that the dispersion volume ratio of deionized water to absolute ethanol is 1:4. The substrate used is a polished silicon wafer, and the polished surfaces of the two polished silicon wafers face each other, and the simple device is placed at an angle of 45°. The circulation speed of the advection pump was 1.0 cm / min. After 40 hours, the advection pump gradually and slowly decreased to 0, and the rest of the operations were the same as in Example 1.

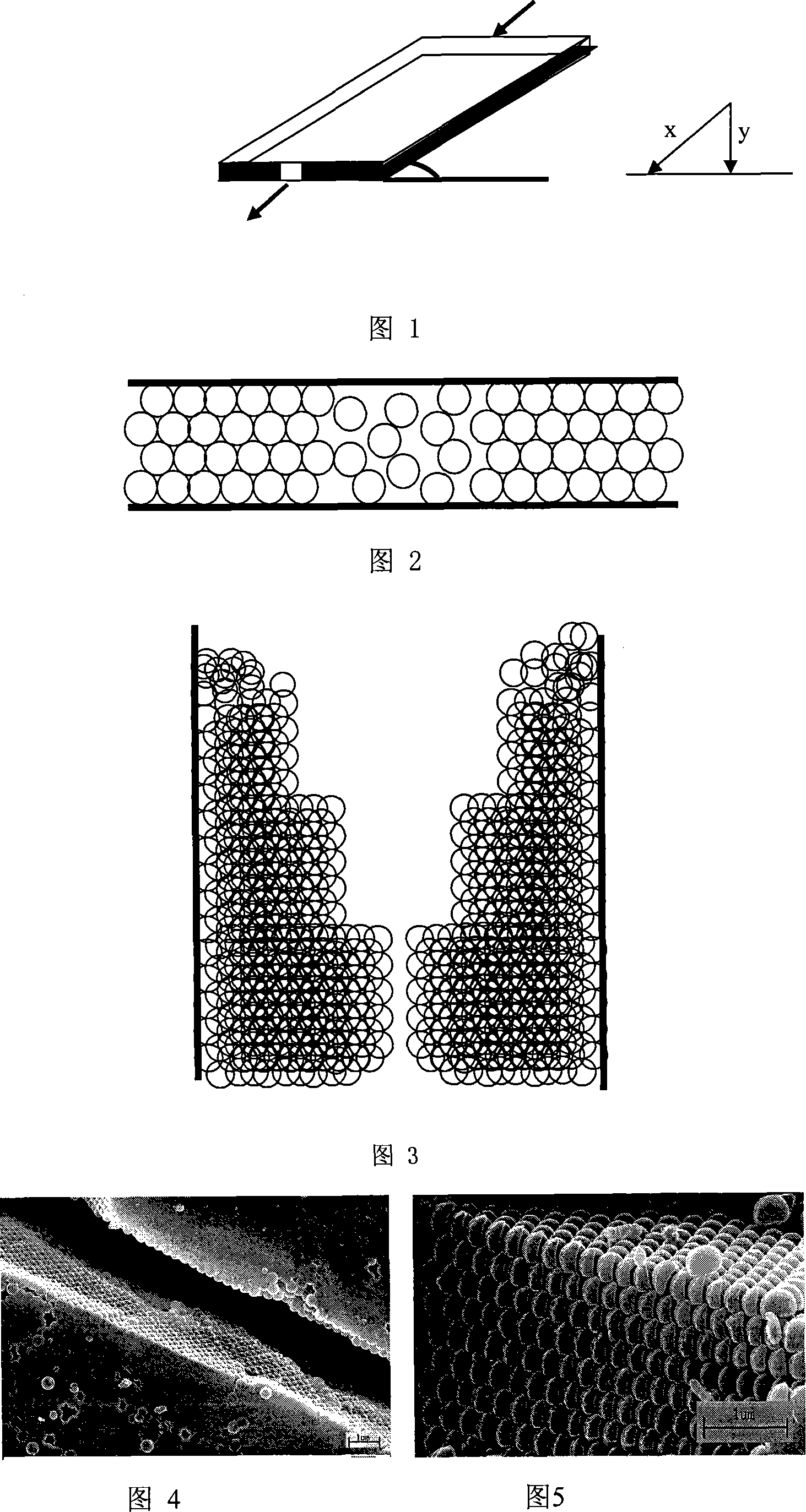

[0022] Figures 2 and 3 roughly represent the schematic diagrams of the cross-section and longitudinal section of the colloidal crystal between the two substrates, respectively. The photonic crystal grows relatively loosely in the central emulsion flow region, and grows densely and firmly on both sides of the substrate, and the obtained area is larger.

[0023] The morphology of the obtained photonic crystal was observed under a scanning electron microscope (ZEISS-SUPRA55, German...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com