Method for producing epsilon-poly-L-lysine by reflux technique

A technology for lysine and lysine fermentation, which is applied in the field of ε-poly-L-lysine production by reflux process, can solve problems such as environmental pollution, and achieve the effects of reducing environmental pollution, reducing losses and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and Embodiment 2

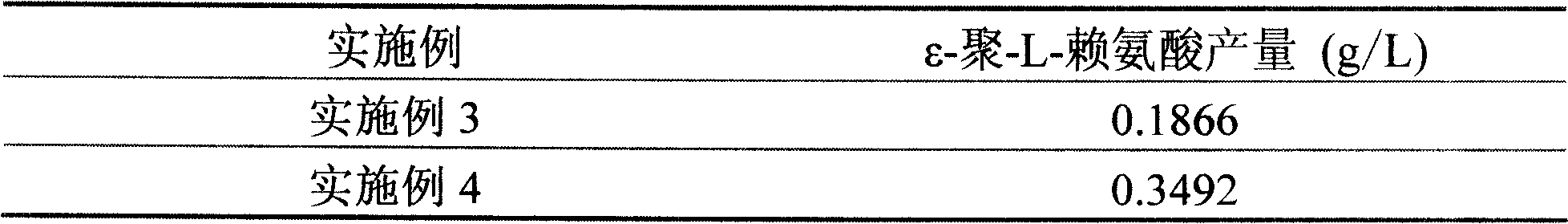

[0018] What embodiment 1 and embodiment 2 described basically is existing production technology;

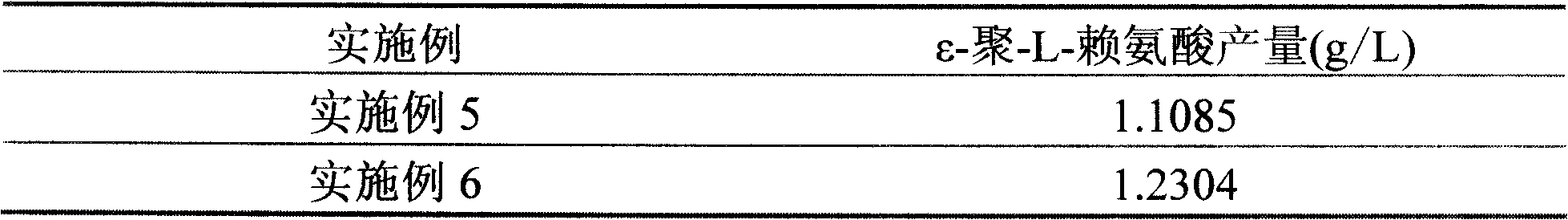

Embodiment 3 and Embodiment 5

[0019] What embodiment 3 and embodiment 5 described basically is existing circulation production process;

[0020] Embodiment 4 and Embodiment 6 are innovative processes compared with Embodiment 3 and Embodiment 5 respectively.

Embodiment 1

[0022] 5L fermenter, filled with 2.7L medium, inoculated with 300mL Streptomyces albicans seed culture solution, cultured at 30°C, when DO dropped to 30%, automatically controlled to 30%, aerobic culture for 96h, air flow rate 3L / min~7.5 L / min. When the pH drops to about 5.8, add ammonia water (25-28%) to maintain the pH at 5.8 until the residual sugar concentration in the fermentation broth drops to 10g / L by feeding the residual sugar concentration to maintain about 10g / L, and at the same time No longer controlling the pH let it drop to 4 naturally and keep it at 4. Feed: Glucose 800g / L, (NH 4 ) 2 SO 4 80g / L.

[0023] Cultivate for 96 hours, finish the fermentation, remove the bacteria and some solids by centrifugation, elute the supernatant with D152 type weakly acidic cation exchange resin, collect the eluate in the early stage, filter, concentrate in vacuum, and dry in a cyclone dryer to obtain ε- poly-L-lysine. The late eluent is reserved for later elution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com