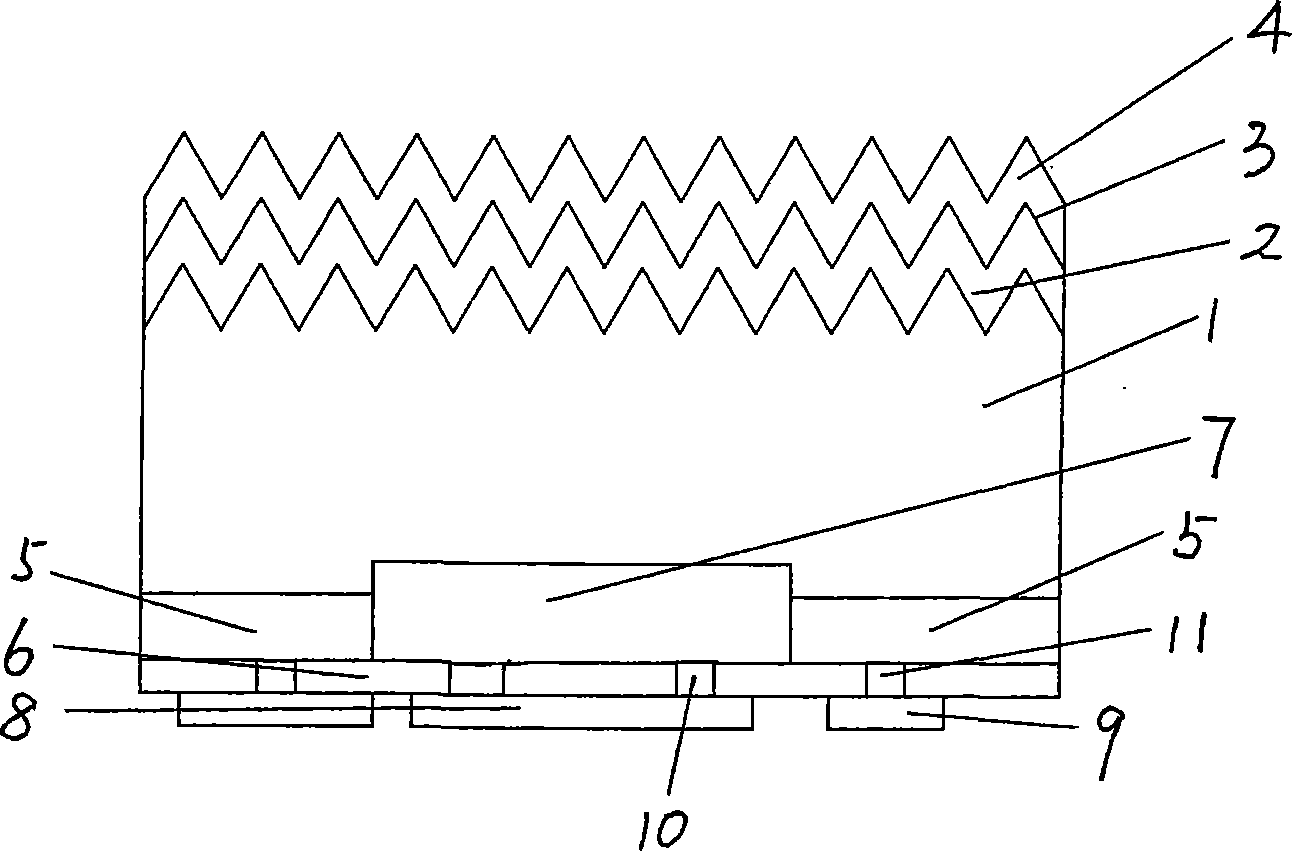

N-type underlay single-side extraction electrode crystal silicon cell and its making method

A technology for crystalline silicon cells and lead-out electrodes, which is applied in final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of complex process and high cost, and achieve the effects of high efficiency, simple manufacturing method and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A method for manufacturing a crystalline silicon battery with electrodes drawn from one side of an N-type substrate, comprising the following steps in sequence:

[0033] (1) Select an N-type single crystal silicon wafer with a resistance of 0.5-6Ω·cm (for example, 0.5Ω·cm, 3Ω·cm, 6Ω·cm), and use a temperature of 50-85°C (for example, 50°C, 70°C, 85°C ℃) of 10-20% (eg 10%, 15%, 20%) concentration of sodium hydroxide solution to remove the damaged layer on each side; then use 1.5-2 % (Example 1.5%, 1.8%, 2%) concentration of sodium hydroxide solution and 1 ~ 3% (Example 1%, 2%, 3%) concentration of isopropanol and 1 ~ 3% (Example 1%, 2%, 3%) concentration corrosion inhibitor sodium silicate is corroded, and corrosion time is 20~40 minutes (example 20 minutes, 30 minutes, 40 minutes), neutralizes and cleans then, forms suede structure;

[0034] (2)N + Layer diffusion: the silicon wafer treated in step (1) is heated with POCl 3 As a diffusion source, phosphorus is diffus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com