Actinic energy ray curable resion composition and use thereof

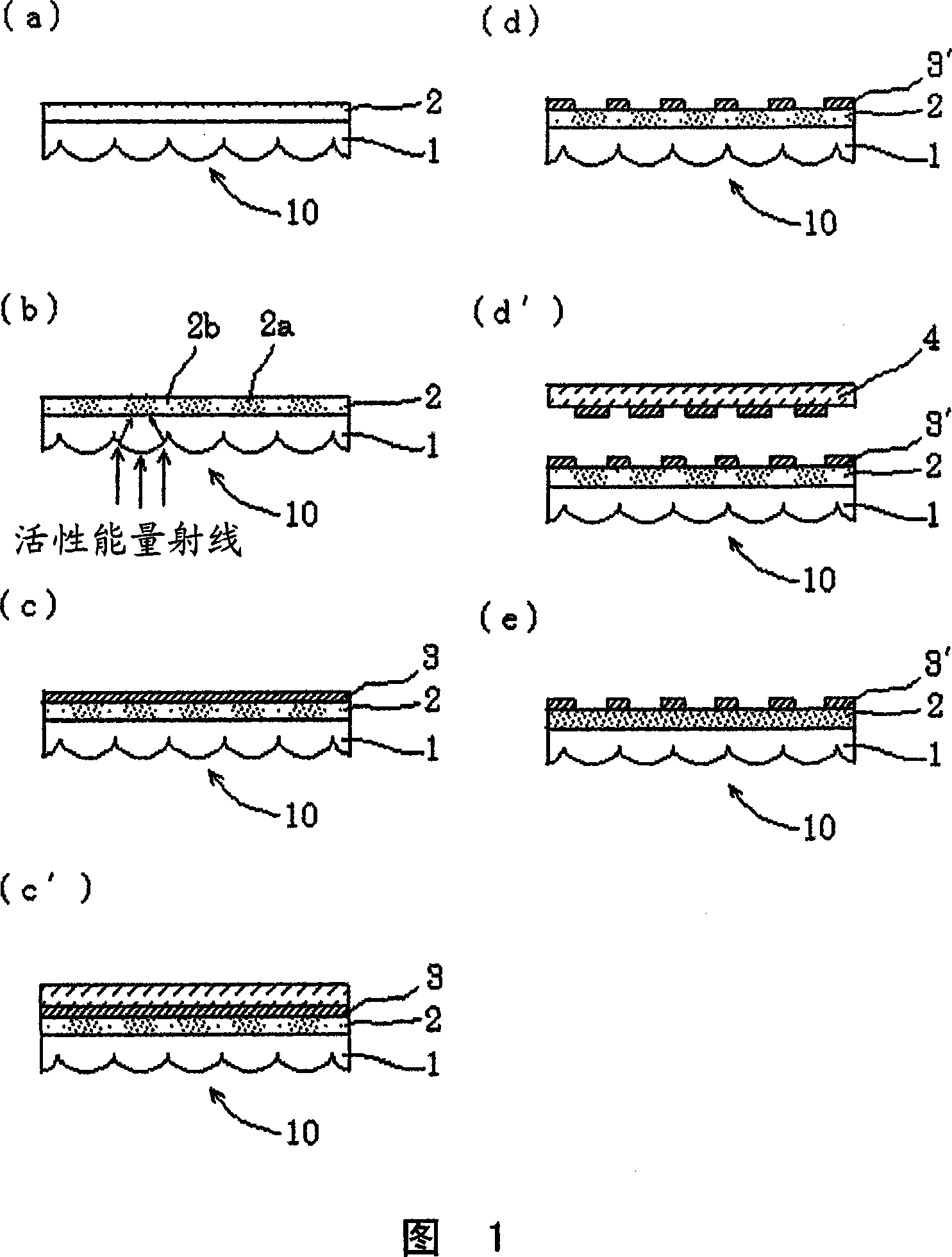

A technology of active energy rays and curable resins, which is applied in the direction of synthetic resin layered products, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve problems such as poor adhesion, poor shape, and difficult to balance, and achieve curing time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0179] Hereinafter, the present invention will be specifically described based on examples, but the present invention is not limited by these examples. In the examples and comparative examples of the present invention, regarding "weight average molecular weight (Mw)", "molecular weight distribution (Mw / Mn)", "glass transition temperature (Tg)", "viscosity", "requirement (A)~ Sufficiency of (C) and (E), "Usability", "Formability", "Pencil Hardness", "Scratch Resistance", "Adhesion", "Storage Stability", "Surface Resistivity" , "Haze value", "Total Light Transmittance", "Minimum Reflectance", and "Oil Streak" are measured or evaluated according to the following descriptions.

[0180] "Weight average molecular weight (Mw)" and "Molecular weight distribution (Mw / Mn)"

[0181] The weight average molecular weight (Mw) and molecular weight distribution (Mw / Mn) of the uncured curable resin composition were measured using the GPC (gel permeation chromatography) apparatus (8020 series,...

Synthetic example

[0211] In a 100ml three-necked flask, add methyl isobutyl ketone (36g), the polymerizable monomer (24g) of the composition shown in Table 1, then carry out nitrogen replacement, then add azobisisobutyronitrile (40mg), at 80 ℃ The mixture was stirred for 6 hours to obtain a polymerization solution.

[0212] Polymerization solution

P-1

P-2

P-3

P-4

P-5

P-6

P-7

parts by weight

20

35

80

30

0

50

0

2-Ethylhexyl Acrylate

parts by weight

0

0

0

5

0

0

0

parts by weight

0

0

0

0

50

0

0

MPTMS *1

parts by weight

80

65

20

65

50

0

0

MPTES *2

parts by weight

0

0

0

0

0

50

100

Mw(×10 3 ) *3

...

Embodiment 1~7

[0217] Examples 1 to 7, Comparative Examples 1 to 6 (Manufacture of Resin Composition, Molding Laminate, and Cured Laminate Molded Article)

[0218] The resin composition shown in Table 2 was prepared, and the resin composition was coated on an acrylic resin plate (trade name: Comoglass Co., Ltd. Kuraray) with a length of 30 cm, a width of 21 cm, and a thickness of 2 mm, so that the thickness of the coating film reached 10 μm, ( Comparative Example 5 was not coated), and dried at 80° C. for 30 seconds to obtain a laminate for molding. After heating the obtained laminated body for molding at 190° C. for 3 minutes, vacuum molding was performed to obtain a box shape with a length of 20 cm, a width of 10 cm, and a height of 10 cm (maximum surface stretching ratio of 25 times), and then by UV irradiation (irradiation amount 2J, HTE-3000B, manufactured by HI-TECH Corporation) to obtain a cured laminated molded body. Table 2 shows the measurement and evaluation results of the resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com