Process of treating heavy metal containing sewage

A treatment method and technology for heavy metals, which are applied in water/sewage treatment, adsorbed water/sewage treatment, neutralized water/sewage treatment, etc., and can solve the problems of backward heavy metal sewage treatment methods, high cost, and difficulty in reaching discharge standards for sewage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

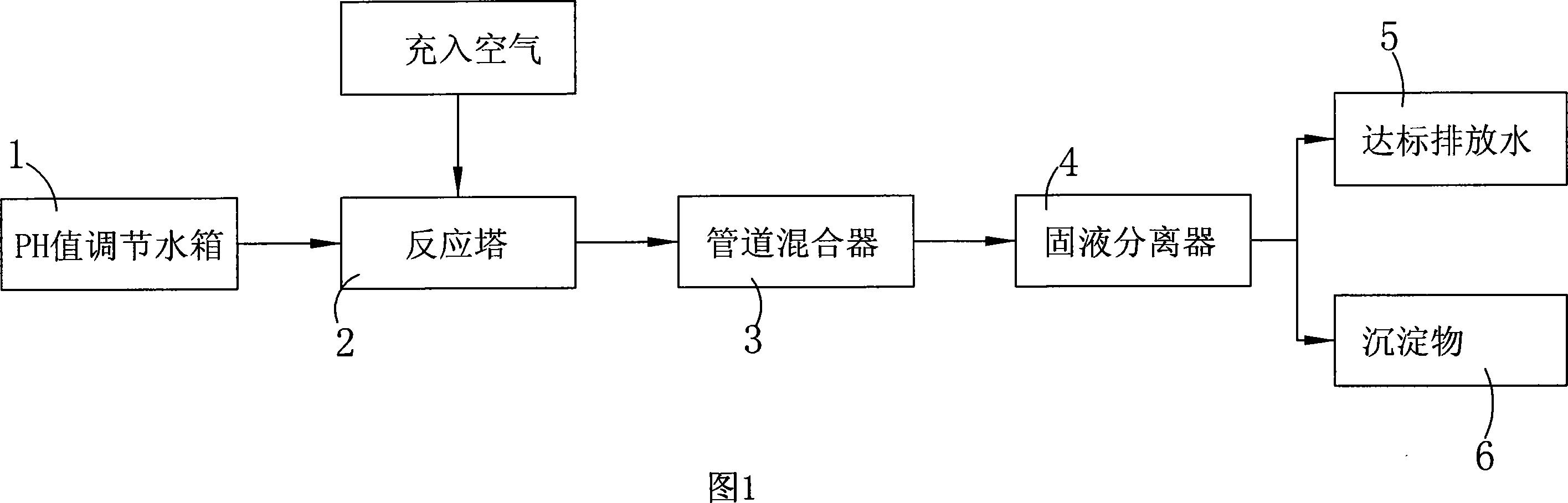

[0016] See Fig. 1, the heavy metal sewage treatment method that the present invention adopts is as follows:

[0017] Firstly, put the sewage into the PH value adjusting water tank 1 to adjust the PH value of the sewage to neutral; the PH value adjusting water tank 1 adjusts the PH value of the sewage by adding sodium hydroxide and water. The pH of sewage is raised by adding sodium hydroxide and lowered by adding water. Add a pH value test induction device on the water tank 1, and the test induction device controls two valves for controlling the outflow and closing of the sodium hydroxide solution and water. In this way, the automatic adjustment of the pH value of the sewage can be realized.

[0018] After the pH value of the sewage is adjusted to neutral, the sewage is introduced into the reaction tower 2 through a water pump. Fillers are placed in the reaction tower 2 as catalysts to cause oxidation-reduction reactions on sewage. Usually, the catalysts added in the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com