Industrialized preparation method for 5 - formoxyl - 3 - ester thiohenic acid

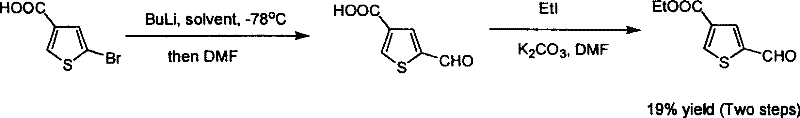

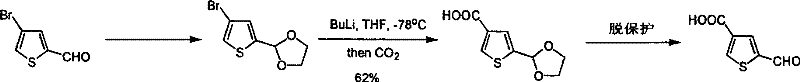

A technology of thiophene carboxylate and formyl, which is applied in the field of industrial preparation of 5-formyl-3-thiophene carboxylate, can solve the problems of harsh reaction conditions, low reaction yield, and difficult availability of raw materials, and avoid low temperature Simple reaction and synthetic route, avoiding the use of organometallic reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

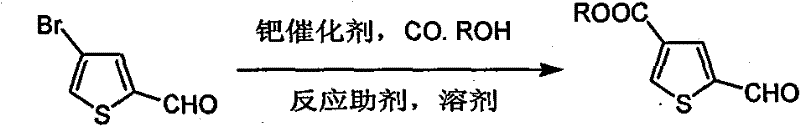

[0019] Synthesis of methyl 5-formyl-3-thiophenecarboxylate via palladium-catalyzed carbonylation of tetrakistriphenylphosphine

[0020]

[0021] Under nitrogen protection, a mixed solution of 4-bromo-2-thiophenecarbaldehyde (100g, 588moml), triethylamine (115g, 1138mml), tetrakistriphenylphosphopalladium (5g, 4.3mmol), methanol (660mL) was prepared at 80 -85°C, 5 atmospheres of carbon monoxide atmosphere, reacted for 14 hours, then cooled to room temperature, concentrated to dryness, added water (400mL) and ethyl acetate (900mL), stirred until completely dissolved, stood to separate the layers, and the organic layer was washed with 2N Hydrochloric acid (300mL), 5% sodium bicarbonate (300mL), and water (300mL) were washed once each; then concentrated, and the crude product was recrystallized with petroleum ether to obtain 78g of the product, with a yield of 88%.

[0022] 1 H NMR (CDCl 3 ): .3.81(s, 3H), 8.33(s, 1H), 8.79(s, 1H), 9.94(s, 1H); MS(m / z): 171

Embodiment 2

[0024] Synthesis of 5-formyl-3-thienylmethanol by palladium acetate+1,3-bis(diphenylphosphino)propane catalyzed carbonylation reaction methyl ester

[0025]

[0026] Palladium acetate (2.25g, 10mmol) and 1,3-bis(diphenylphosphino)propane (8.3g, 20mmol) were added to 4-bromo-2-thiophenecarbaldehyde (80.5g, 0.50mol) and triethylamine ( 242.2g, 2.22mol) of dimethylformamide (4L)-methanol (1L) solution. 70°C, under normal pressure, reacted under carbon monoxide atmosphere for two days. The catalyst was removed by filtration, concentrated and recrystallized by n-hexane to obtain 72 g (yield: 85%).

Embodiment 3

[0028] Synthesis of 5-formyl-3- Ethyl thiophenecarboxylate

[0029]

[0030] Palladium chloride (18.4g, 0.104mol) and 2,2'-bis(diphenylphosphino)-1,1'-binaphthyl (27.6g, 0.044mol) were added to 4-bromo-2-thiophenecarbaldehyde ( 80.5g, 0.50mol) and triethylamine (242.2g, 2.22mol) in methanol (4L)-acetonitrile (2L) solution. 100°C, under normal pressure, reacted under carbon monoxide atmosphere for two days. The catalyst was removed by filtration and the reactant was concentrated and then recrystallized from petroleum ether to obtain 75 g (yield: 82%).

[0031] 1 H NMR (CDCl 3 ): .1.21(t, 3H), 4.20(q, 2H), 8.31(s, 1H), 8.76(s, 1H), 9.96(s, 1H); MS(m / z): 185

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com