Glutin nano fabric film containing nano silver and preparation and application thereof

A nanofiber film and nanofiber technology, which is applied in fiber treatment, textiles and papermaking, medical science, etc., can solve the problems of easy agglomeration, large diameter of nanosilver particles, and difficulty in uniform dispersion, so as to reduce shedding and agglomeration, The effect of reducing the amount of silver added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

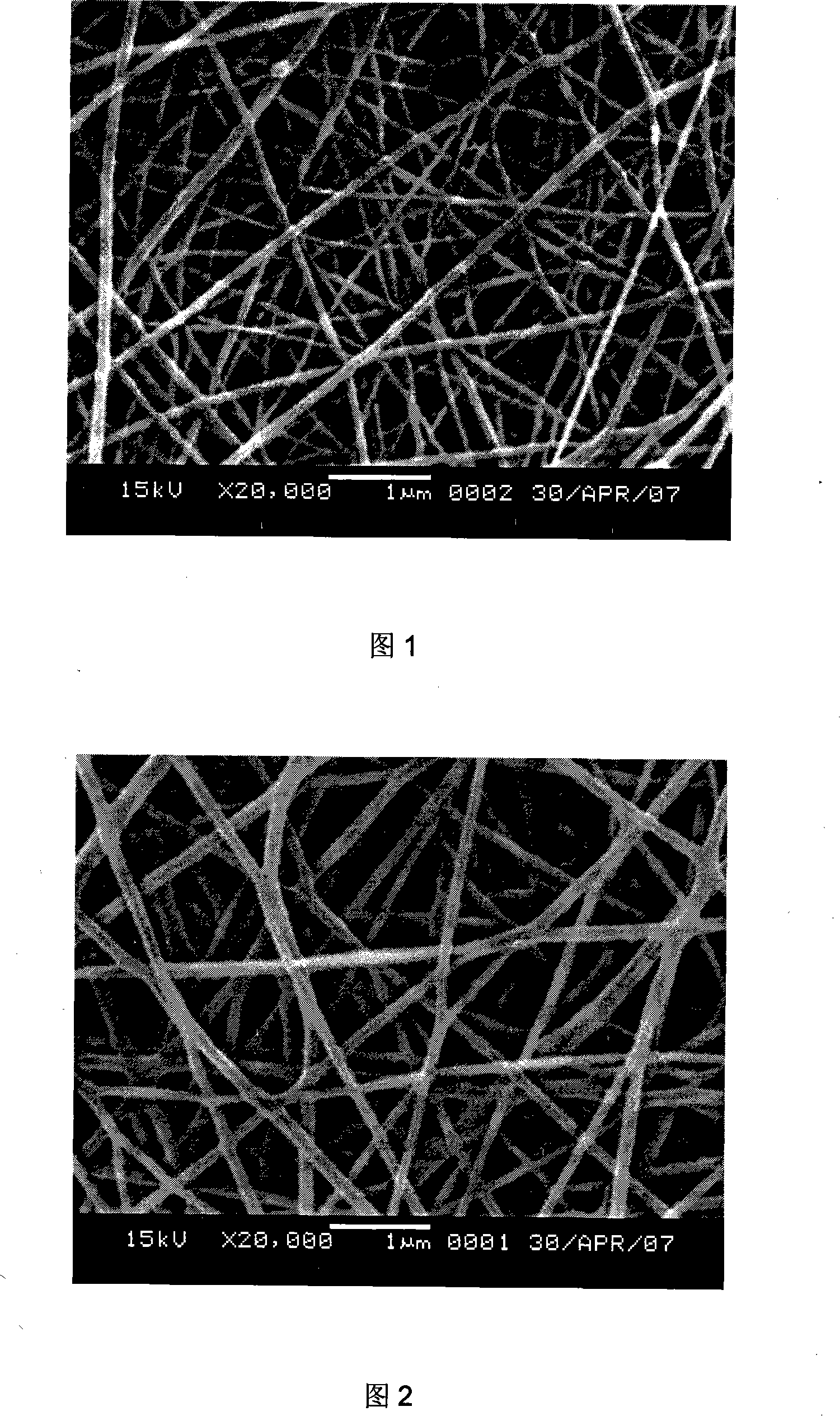

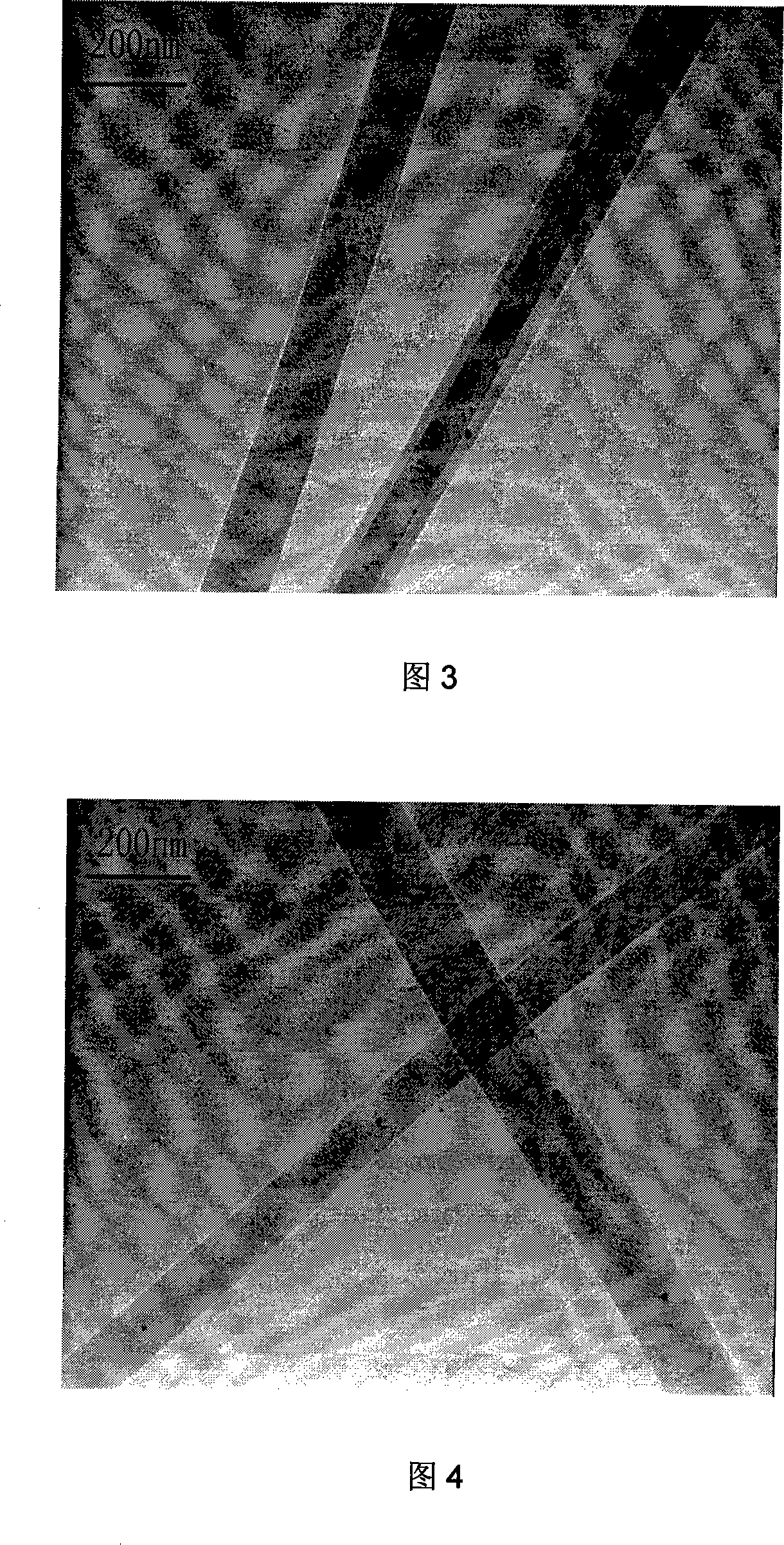

Embodiment 1

[0022] Accurately weigh 1.5 grams of medical grade gelatin and dissolve it in 10 milliliters of formic acid concentrated solution. The formic acid concentration is 88%. After sealing, stir magnetically at room temperature. After the gelatin is completely dissolved, add 0.0075 grams of silver nitrate powder. After sealing, continue to magnetically stir at room temperature. Stir until the silver nitrate is completely dissolved to form a bright yellow transparent liquid. After standing still for 15 minutes, transfer the spinning solution to a plastic syringe with a voltage of 22kV and a syringe pump with a speed of 0.4ml / h. Aluminum foil is used for receiving, and the receiving distance is 14cm, spinneret diameter is 0.7mm, electrospun gelatin / silver nanofiber membrane was obtained on aluminum foil, vacuum dried at 40°C for 24h, placed under ultraviolet light for 3h, and gelatin nanofiber membrane containing nanosilver was obtained. The average diameter of the obtained fibers was ...

Embodiment 2

[0024] Accurately weigh 1.5 grams of medical grade gelatin and dissolve it in 10 milliliters of formic acid concentrated solution. The formic acid concentration is 88%. After sealing, stir magnetically at room temperature. After the gelatin is completely dissolved, add 0.0150 grams of silver nitrate powder. After sealing, continue to magnetically stir at room temperature. Stir until the silver nitrate is completely dissolved to form a bright yellow transparent liquid. After standing still for 15 minutes, transfer the spinning solution to a plastic syringe with a voltage of 22kV and a syringe pump with a speed of 0.4ml / h. Aluminum foil is used for receiving, and the receiving distance is 14cm, spinneret diameter is 0.7mm, electrospun gelatin / silver nanofiber membrane was obtained on aluminum foil, vacuum dried at 40°C for 24h, placed under ultraviolet light for 3h, and gelatin nanofiber membrane containing nanosilver was obtained. The average diameter of the obtained fibers was ...

Embodiment 3

[0026] Accurately weigh 1.5 grams of medical grade gelatin and dissolve it in 10 milliliters of formic acid concentrated solution, the concentration of formic acid is 88%. After sealing, stir magnetically at room temperature. After the gelatin is completely dissolved, add 0.0300 grams of silver nitrate powder. After sealing, continue to magnetically stir at room temperature. Stir until the silver nitrate is completely dissolved to form a bright yellow transparent liquid. After standing still for 15 minutes, transfer the spinning solution to a plastic syringe with a voltage of 22kV and a syringe pump with a speed of 0.4ml / h. Aluminum foil is used for receiving, and the receiving distance is 14cm, spinneret diameter is 0.7mm, electrospun gelatin / silver nanofiber membrane was obtained on aluminum foil, vacuum dried at 40°C for 24h, placed under ultraviolet light for 3h, and gelatin nanofiber membrane containing nanosilver was obtained. The average diameter of the obtained fibers w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com