'Piteguo' beverage and its preparation process

A beer special fruit and beverage technology, which is applied in the beer special fruit beverage product and its manufacturing field, can solve the problems of fresh fruit rot and waste, waste of resources, difficult long-term storage and long-distance transportation, etc., to achieve increased enzyme activity, long processing cycle, and retention The effect of natural flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

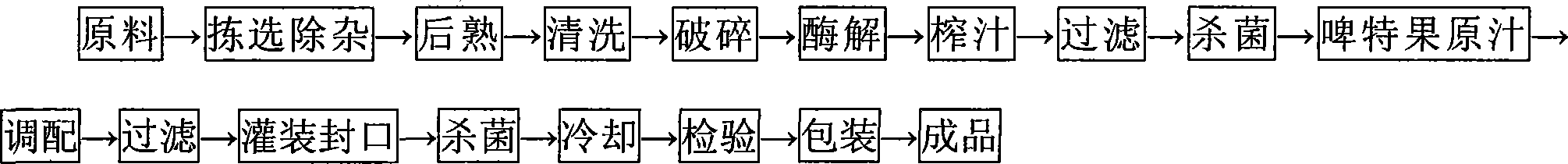

Image

Examples

Embodiment 1

[0040] The weight ratio of raw materials: 20% of beer special fruit juice, 8% of white sugar, 0.3% of citric acid, 0.15% of malic acid, 0.2% of honey, 0.05% of caramel pigment, 0.02% of sodium tripolyphosphate, sodium hexametaphosphate 0.03%, xanthan gum 0.03%, and the rest is purified water.

[0041] Manufacturing method of beer fruit beverage: ①Sorting and selecting the fresh picked beer fruit to remove moldy and rotten fruit, fruit damaged by diseases and insect pests, damaged fruit and other sundries; On the 20th day, the peel turns gray-black, the core and pulp become soft, the flesh is delicate, sweet and sour, juicy, rich in aroma, and produces the unique flavor of beet fruit; For the beer fruit, wash the soil, microorganisms, residual pesticides, etc. adhering to the surface of the fruit with pure water, and further remove unqualified raw materials while cleaning; The naturally after-ripened beer fruit is broken separately, and the crushing particle size is 3-4mm. At ...

Embodiment 2

[0043] The weight ratio of raw materials: 30% of beer special fruit juice, 6% of white sugar, 0.2% of citric acid, 0.2% of malic acid, 0.25% of honey, 0.05% of caramel pigment, 0.02% of sodium tripolyphosphate, sodium hexametaphosphate 0.04%, xanthan gum 0.04%, and the rest is purified water.

[0044] The manufacturing method of beer special fruit beverage is with embodiment 1. Among them, the color-protecting agent added when the beer fruit is broken is 0.08% vitamin C and 0.1% citric acid; After the mud is mixed at a ratio of 1:15, adjust the pH to 4.0 and the temperature at 35°C, add 0.02% pectinase and 0.008% glucoamylase for enzymolysis; add gelatin-silica gel-bentonite compound clarifier to clarify after squeezing the juice, and the dosage of gelatin is 0.8 %, the dosage of silica gel is 1.4%, and the dosage of bentonite is 0.8%; the sterilization temperature of beer teguo original juice is 130°C, and the time is 4s; after mixing and filling, it is sterilized at 90°C fo...

Embodiment 3

[0046] The weight ratio of raw materials: 15% of beer special fruit juice, 9% of white sugar, 0.4% of citric acid, 0.15% of malic acid, 0.5% of honey, 0.08% of caramel pigment, 0.04% of sodium tripolyphosphate, sodium hexametaphosphate 0.02%, xanthan gum 0.02%, and the rest is purified water.

[0047] The manufacturing method of beer special fruit beverage is with embodiment 1. Among them, the color-protecting agent added when the beer fruit is broken is 0.03% vitamin C and 0.5% citric acid; After the mud is mixed in a ratio of 1:5, adjust the pH to 3.5 and the temperature to 35°C, add 0.004% pectinase for enzymatic hydrolysis; add gelatin-silica gel-bentonite compound clarifier to clarify after squeezing the juice and centrifuging, the amount of gelatin is 1.2%, and the amount of silica gel is 1.0 %, the amount of bentonite is 0.8%; the sterilization temperature of the original beer teguo juice is 135°C, and the time is 3s; after mixing and filling, it is sterilized at 80°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com