Preparation method for polymer dispersion liquid crystal thin film

A technology for dispersing liquid crystals and polymers, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of insufficient mechanical strength of polymer networks, and the stability of electro-optic properties of PDLC films cannot meet the application requirements, and achieve low driving voltage, The effect of small shrinkage and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

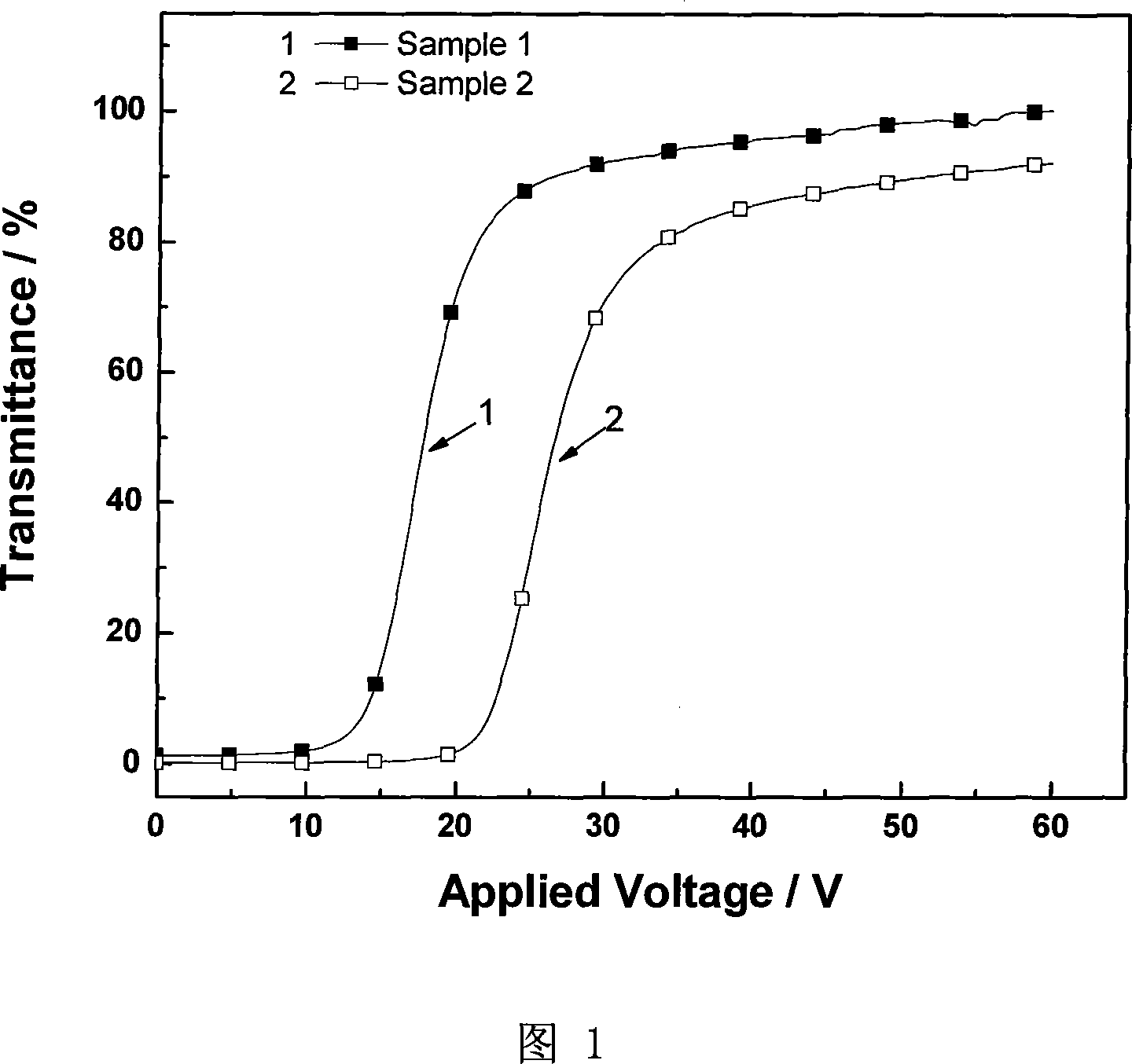

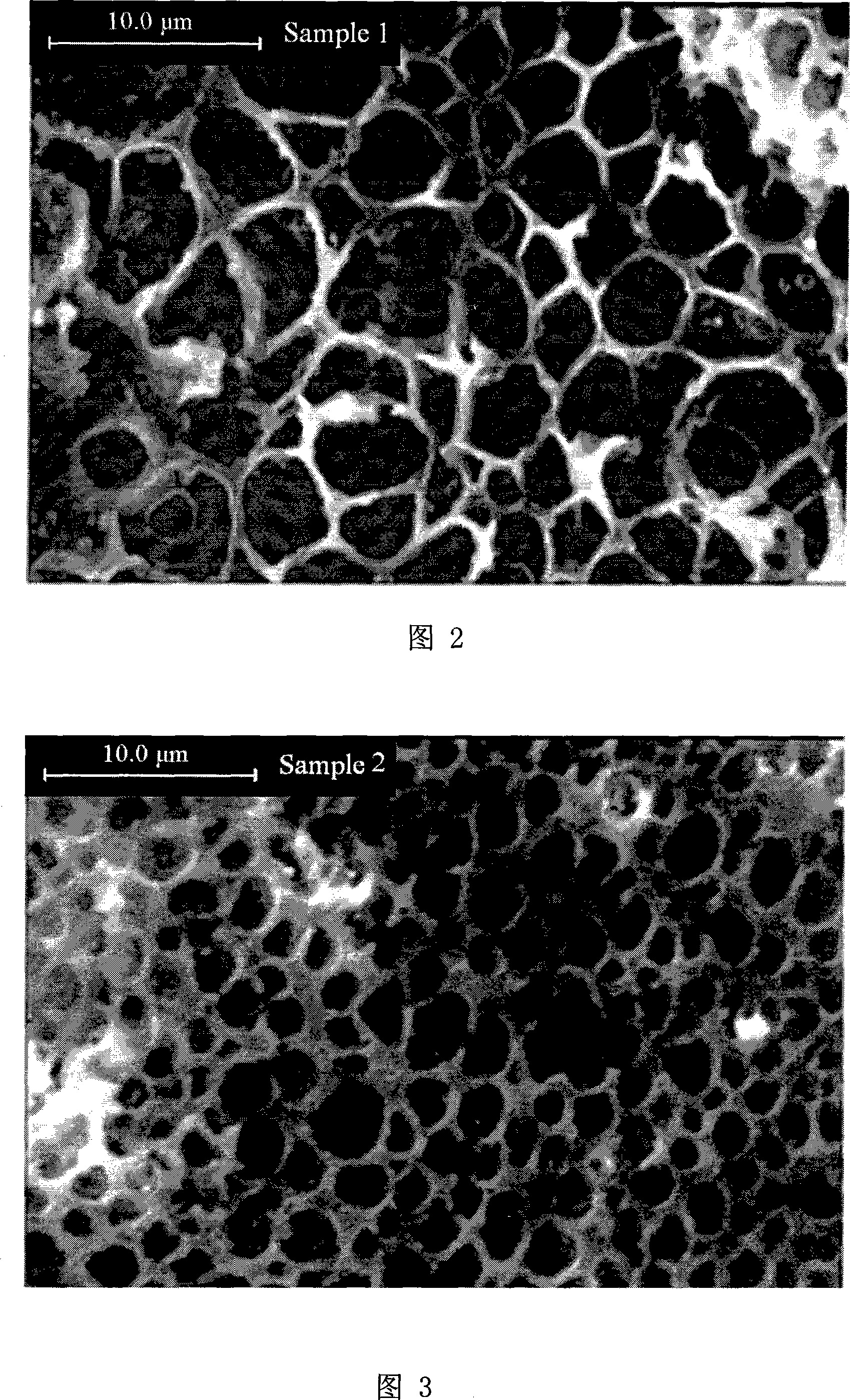

[0028] This embodiment is a method for preparing a low-driving voltage, high-contrast PDLC film, which is carried out in the following steps:

[0029] (1) Mix 1,2-di-n-butylene phenylacetylene compound, rigid bifunctional acrylate polymerizable monomer, and methyl methacrylate in a mass ratio of 8:2:3, and use the mixed system as polymerized monomers. The chemical structure of 1,2-di-n-butylphenylacetylene is:

[0030]

[0031] The chemical structure of the rigid difunctional acrylate polymerizable monomer is:

[0032]

[0033] (2) Mix the polymerized monomers of nematic liquid crystal and polymer-dispersed liquid crystal at a mass ratio of 2:8 to form an isotropic liquid at room temperature (-0.5°C). The nematic liquid crystal selected is SLC7011-100 (Shijiazhuang Yongsheng Huaqing LCD Co., Ltd.).

[0034] (3) Evenly mix the photoinitiator, glass microspheres and isotropic liquid, sandwich them between two pieces of transparent indium tin oxide conductive glass or tr...

Embodiment 2

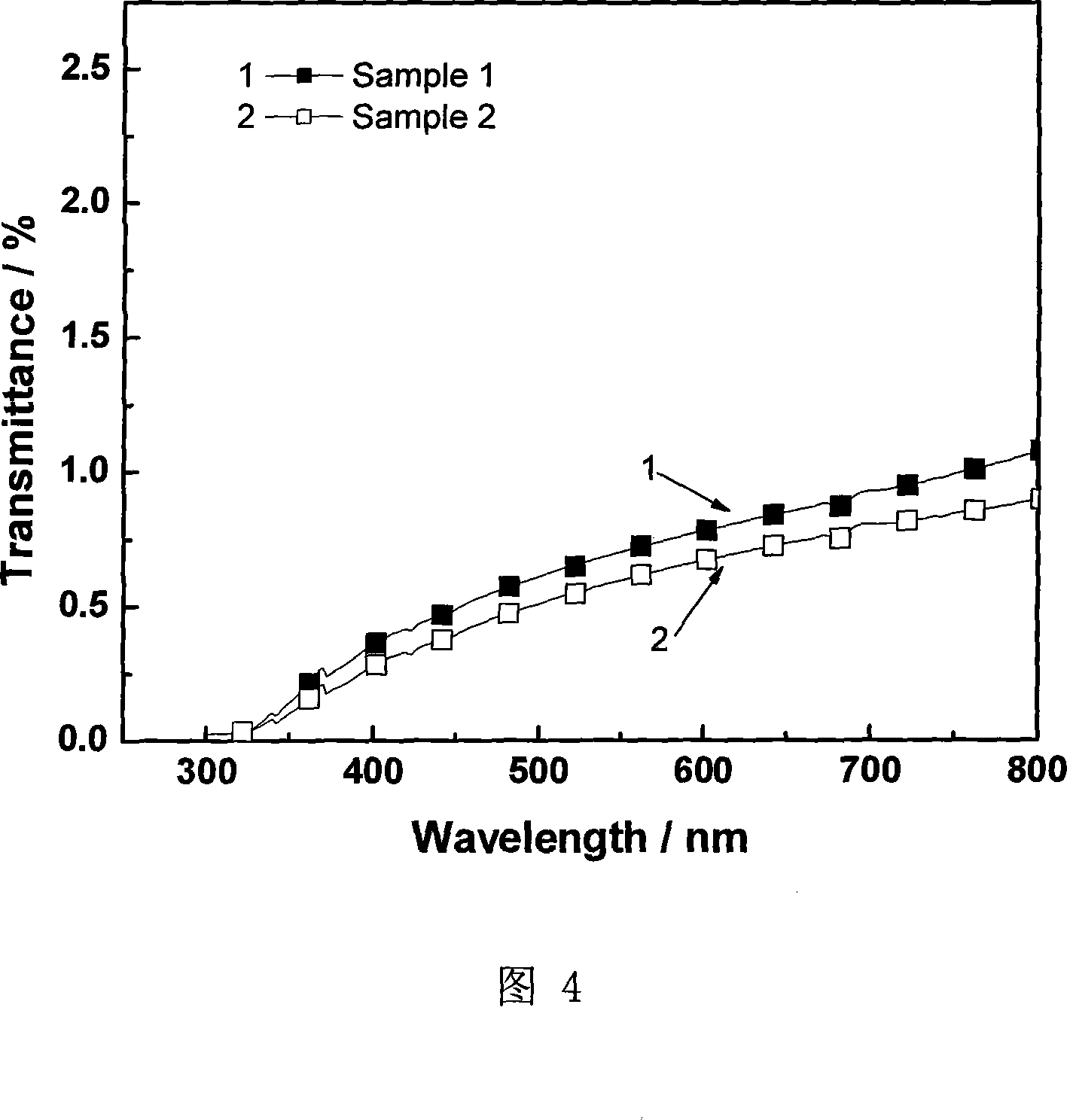

[0037] This embodiment is a method for preparing a low-driving voltage, high-contrast PDLC film, which is carried out in the following steps:

[0038] (1) Mix 1,2-di-n-butylphenylacetylene compound, rigid bifunctional acrylate polymerizable monomer, and methyl methacrylate in a mass ratio of 8:3:2, and use the mixed system as polymerized monomers.

[0039] (2) Mix the polymerized monomers of nematic liquid crystal and polymer-dispersed liquid crystal at a mass ratio of 6:4 to form an isotropic liquid at room temperature (-0.5°C). The nematic liquid crystal selected is SLC7011-100 (Shijiazhuang Yongsheng Huaqing LCD Co., Ltd.).

[0040] (3) Evenly mix the photoinitiator, glass microspheres and isotropic liquid, sandwich them between two pieces of transparent indium tin oxide conductive glass or transparent indium tin oxide conductive plastic film, and press evenly to form a film layer with a thickness of 18 μm . The photoinitiator is Irgacure 651 (Tokyo Chemical Company), an...

Embodiment 3

[0043] This embodiment is a method for preparing a low-driving voltage, high-contrast PDLC film, which is carried out in the following steps:

[0044] (1) Mix 1,2-di-n-butylphenylacetylene compound, rigid bifunctional acrylate polymerizable monomer, and methyl methacrylate in a mass ratio of 8:3:2, and use the mixed system as polymerized monomer.

[0045] (2) Mix the polymerized monomers of nematic liquid crystal and polymer-dispersed liquid crystal at a mass ratio of 8:2 to form an isotropic liquid at room temperature (-0.5°C). The nematic liquid crystal selected is SLC7011-100 (Shijiazhuang Yongsheng Huaqing LCD Co., Ltd.).

[0046] (3) Evenly mix the photoinitiator, glass microspheres and isotropic liquid, sandwich them between two pieces of transparent indium tin oxide conductive glass or transparent indium tin oxide conductive plastic film, and press evenly to form a film layer with a thickness of 20 μm . The photoinitiator is Irgacure 651 (Tokyo Chemical Company), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com