Method of producing three fundamental quantum dot CdSeTe

A ternary quantum dot and quantum dot technology, which is applied in the field of nanotechnology preparation, can solve the problems of high synthesis temperature, limited scale preparation, and high price, and achieve the effect of simple operation and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

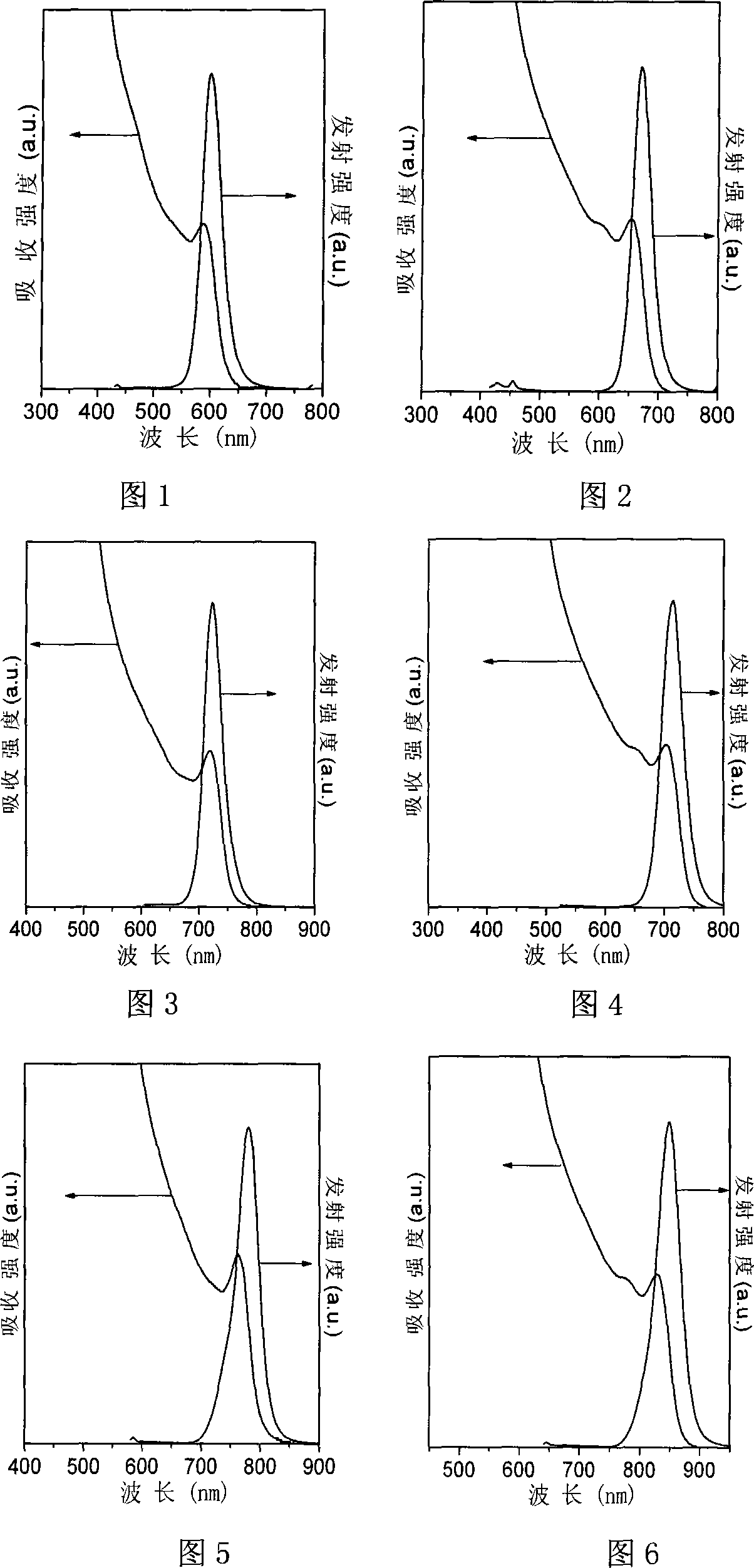

Image

Examples

Embodiment 1

[0022] (a) Measure 0.65mL oleic acid and 9.35mL liquid paraffin and mix them in a three-neck bottle A, heat to 150°C, add 0.13g CdO powder, make the molar ratio of Cd to oleic acid 1:2, and wait for the CdO powder After complete dissolution, a Cd precursor solution is obtained;

[0023] (b) Measure 9.87mL of liquid paraffin and 0.13mL of TOP and mix them in the three-necked bottle B, add 0.004g of Se powder to make the molar ratio of Se to TOP 1:5, make Se under the condition of nitrogen protection and rapid mechanical stirring. Powder dissolves completely, obtains TOPSe solution;

[0024] (c) Measure 9.67mL of liquid paraffin and 0.33mL of TOP and mix them in a three-neck flask C, add 0.019g of Te powder to make the molar ratio of Te to TOP 1:5, make Te under the condition of nitrogen protection and rapid mechanical stirring. The powder was completely dissolved to obtain a TOPTe solution.

[0025] (d) Mix the TOPSe solution and the TOPTe solution so that the molar ratio of ...

Embodiment 2

[0030] (a) Measure 1.3mL of oleic acid and 8.7mL of liquid paraffin and mix them in a three-neck flask A, heat to 150°C, add 0.26g of CdO powder, make the molar ratio of Cd to oleic acid 1:2, and wait for the CdO powder After complete dissolution, a Cd precursor solution is obtained;

[0031] (b) Measure 9.5mL of liquid paraffin and 0.5mL of TOP and mix them in the three-necked bottle B, add 0.008g of Se powder to make the molar ratio of Se to TOP 1:10, make Se under the condition of nitrogen protection and rapid mechanical stirring. Powder dissolves completely, obtains TOPSe solution;

[0032](c) Measure 8.5mL of liquid paraffin and 1.5mL of TOP and mix them in a three-neck flask C, add 0.038g of Te powder to make the molar ratio of Te to TOP 1:10, and make Te under the conditions of nitrogen protection and rapid mechanical stirring. The powder was completely dissolved to obtain a TOPTe solution.

[0033] (d) Mix the TOPSe solution and the TOPTe solution so that the molar r...

Embodiment 3

[0038] (a) Measure 1.3mL of oleic acid and 8.7mL of liquid paraffin and mix them in a three-neck flask A, heat to 150°C, add 0.26g of CdO powder, make the molar ratio of Cd to oleic acid 1:2, and wait for the CdO powder After complete dissolution, a Cd precursor solution is obtained;

[0039] (b) Measure 9mL of liquid paraffin and 1mL of TOP and mix them in the three-necked bottle B, add 0.016g of Se powder to make the molar ratio of Se to TOP 1:10, make the Se powder completely under the condition of nitrogen protection and rapid mechanical stirring Dissolving, obtains TOPSe solution;

[0040] (c) Measure 9 mL of liquid paraffin and 1 mL of TOP and mix them in a three-neck flask C, add 0.026 g of Te powder to make the molar ratio of Te to TOP 1:10, and make the Te powder completely under nitrogen protection and rapid mechanical stirring. Dissolved to obtain TOPTe solution.

[0041] (d) Mix the TOPSe solution and the TOPTe solution so that the molar ratio of Se to Te is 1:1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com