Production method of immobilized microorganism fermenting propionic acid

A technology for immobilizing microorganisms and production methods, applied in microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve the problems of being easily decomposed by microorganisms, affected by cell activity, poor mass transfer performance, etc., to reduce acetic acid. The effect of presence, reduction in usage, and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Bacterial species and medium used Table 1

[0030] serial number

Bacteria name (Chinese, Latin)

Incline medium

1

Propionibacterium freunderi

Propionibacteria

freudenreichii

IFFI.10019

Basic medium (g / L): peptone 10,

Sucrose 20, Yeast Extract 10, Ammonium Phosphate 5

(pH=7.2-7.4)

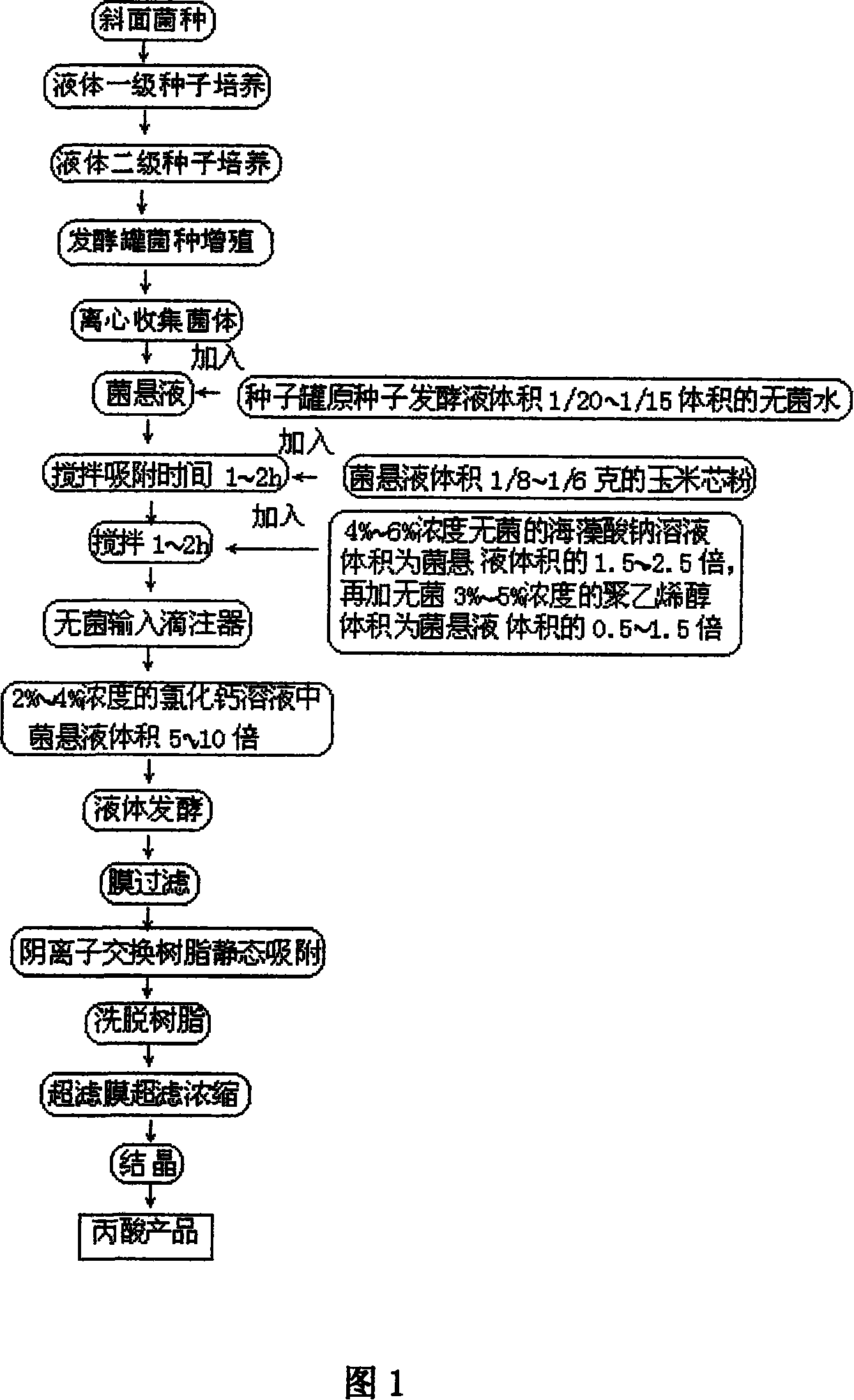

[0031] The method for producing propionic acid fermented by immobilized propionic acid bacteria comprises the following steps: (1) culture of bacteria (2) immobilized propionic acid bacteria frescheri (3) liquid submerged fermentation (4) extraction process of propionic acid:

[0032](1) Wherein the bacterial classification cultivation procedure: think that the production bacterial classification adopts Propionibacteria freudenreichii test tube slant bacterial classification, shakes the flask amplification cultivation, the seed tank enlargement cultivation method. Incline culture: basic medium (g / L)...

Embodiment 2

[0037] Bacterial species and medium used Table 1

[0038] serial number

Bacteria name (Chinese, Latin)

Incline medium

[0039] 1

Propionibacterium freunderi

Propionibacteria

freudenreichii

IFFI.10019

Basic medium (g / L): peptone 10,

Sucrose 20, Yeast Extract 10, Ammonium Phosphate 5

(pH=7.2-7.4)

[0040] (1) Strain cultivation process: adopt Propionibacteria freudenreichii test tube slant bacterial classification→shake flask amplification→seed tank expansion cultivation method for production strain. Cultivation of slant strains: use the corresponding culture medium and add 25g agar for the above strains, culture at 35°C for 48 hours, put them in a 4°C refrigerator for storage; the shake flask culture conditions: temperature 40°C, speed 180 rpm, Time 30h; seed tank cultivation conditions: temperature 40°C, ventilation 13m 3 / h, tank pressure 0.09MPa, time 60 hours.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com