Steel air-ethanol ionic oxynitrocarburizing process

A technology of nitrogen, carbon, oxygen, and ion nitriding, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of glow extinguishing, low surface hardness, non-renewable gasoline, etc., and achieve the simplification of the device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

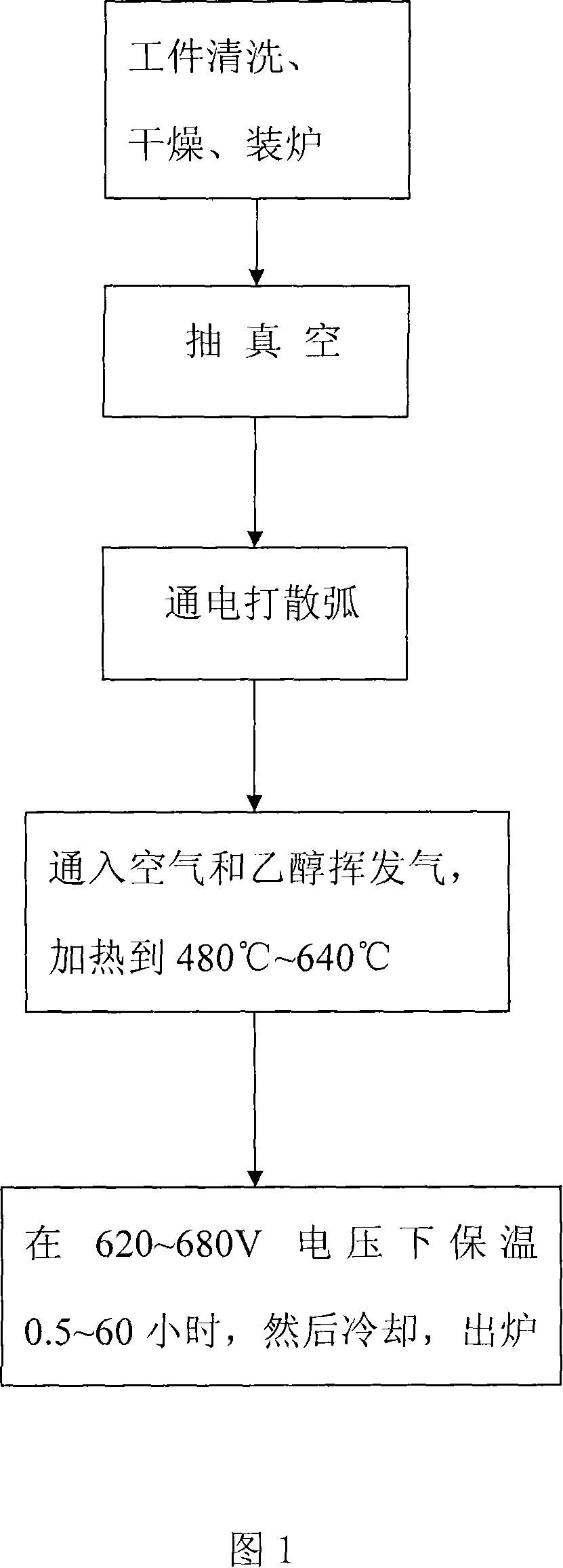

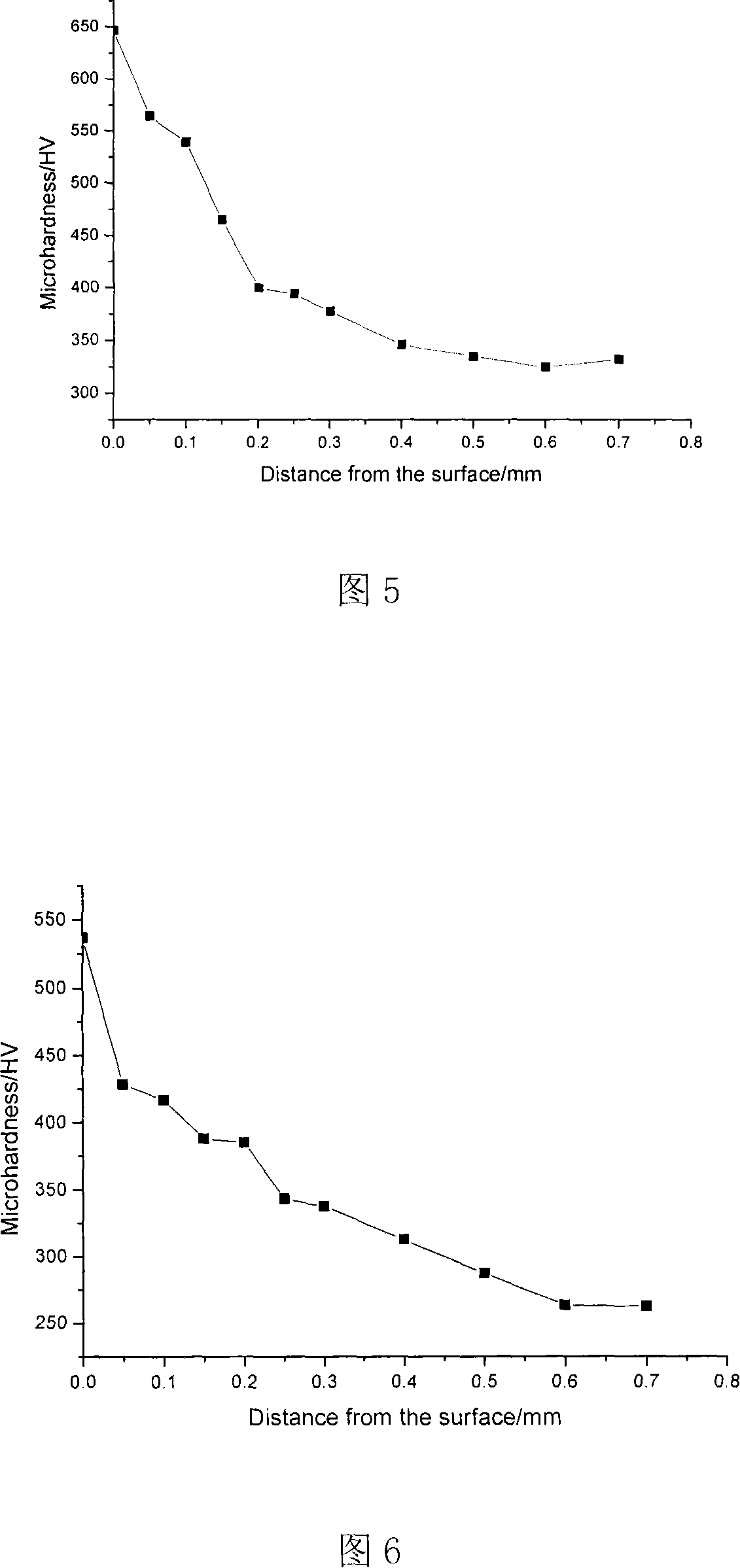

[0025] Example 1: Air-ethanol ion nitrocarburizing process of 40Cr steel

[0026] (1) Clean and dry the workpiece after quenching and tempering, and place it on the cathode disc in the ion nitriding furnace;

[0027] (2) Close the furnace body, and use a mechanical pump to evacuate the ion nitriding furnace to 100Pa;

[0028] (3) Turn on the power switch, input an adjustable DC voltage of 900V to the cathode and anode to break up the arc in the furnace, and then adjust the DC voltage until the arc is not broken up;

[0029] (4) Into the ion nitriding furnace, air and ethanol volatile gas with a flow ratio of 25:3 are simultaneously introduced, and the workpiece is heated to 480°C at a heating rate of 100°C / hour;

[0030] (5) After 5 hours of heat preservation at 680V, turn off the gas source and power supply, and cool down to 100°C with the cooling rate of 100°C / hour to stop the furnace. After the workpiece is cooled to room temperature, turn on the furnace and take out the...

Embodiment 2

[0031] Embodiment 2: Air-ethanol ion nitrogen carbon oxygen co-infiltration process of 40Cr steel

[0032] (1) (2) (3) step is identical with embodiment 1 (1) (2) (3) step;

[0033] (4) Air and ethanol volatile gas with a flow ratio of 25:3 are simultaneously introduced into the ion nitriding furnace, and the workpiece is heated to 500°C at a heating rate of 150°C / hour;

[0034] (5) After 5 hours of heat preservation at 640V, turn off the gas source and power supply, and cool down to 100°C with the cooling rate of 100°C / hour to stop the furnace. After the workpiece is cooled to room temperature, turn on the furnace and take out the workpiece.

Embodiment 3

[0035] Embodiment 3: Air-ethanol ion nitrocarburizing process of 40Cr steel

[0036] (1) (2) (3) step is identical with embodiment 1 (1) (2) (3) step;

[0037] (4) Into the ion nitriding furnace, air and ethanol volatile gas with a flow ratio of 25:6 are simultaneously introduced, and the workpiece is heated to 520°C at a heating rate of 120°C / hour;

[0038] (5) After 5 hours of heat preservation at 680V, turn off the gas source and power supply, and cool down to 100°C with the cooling rate of 100°C / hour to stop the furnace. After the workpiece is cooled to room temperature, turn on the furnace and take out the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com