Edible meat improving agent and method for producing edible meat processed food using the edible meat improving agent

A technology of edible meat and manufacturing method, applied in food preparation, application, food science, etc., can solve the problems of hard taste, lack of fiber feeling, discharge, etc., achieve the effect of less taste and maintain output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

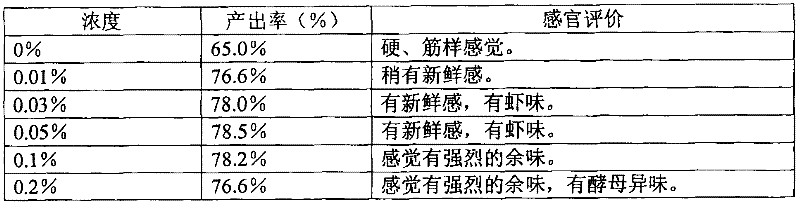

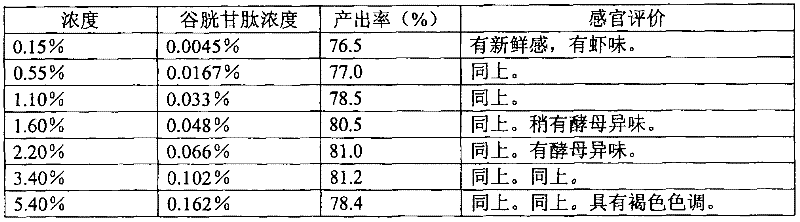

[0042] (Experimental Example 1) Effect of Glutathione in the present invention

[0043] 1000 grams of raw shrimps (25-30 grams / piece) with shells and heads removed were immersed in (1) reduced glutathione (reagent), (2) Torula torulopisis (Torula torulopisis) extract (Xing People's Co., Ltd. product, containing 3% glutathione) as glutathione is dissolved or dispersed in 1000 grams of tap water and is prepared in the solution, the amount of glutathione is 0.01~0.2% relative to the raw shrimp, After that, immerse at 8-10 degreeC for 15 hours. Then, the water liquid was removed, wrapped with a coat, and fried at 170° C. for 4 minutes, and the obtained shrimp tempeh was put into an airtight storage container, and stored in a refrigerator for 24 hours. Peel off the coat, and perform sensory evaluation on its output rate and taste with raw shrimp. The results are shown in Table 1-1 and Table 1-2. As can be seen from Table 1-1 and Table 1-2, the glutathione concentration is about ...

experiment example 2

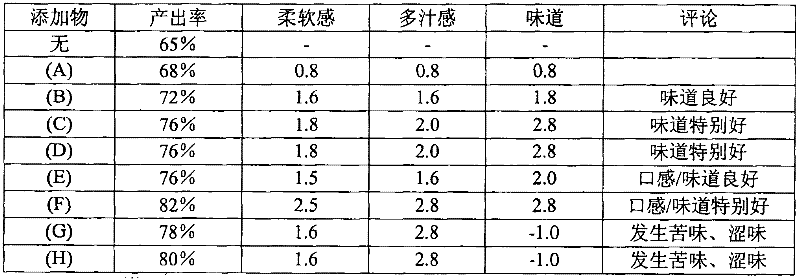

[0049] (Experimental example 2) Addition effect of baking salt and glutathione in the present invention

[0050] Immerse 1000 g of raw shrimp (25-30 g / tail) with the shell and head removed in a solution prepared by dissolving or dispersing 30 g (A)-(F) in 1000 g of tap water respectively. Dipping for 15 hours at ~10°C, wherein (A) is sodium chloride, (B) is a mixture containing 98.5 grams of sodium chloride and 1.5 grams of magnesium chloride hexahydrate (containing 0.18% magnesium), and (C) is the mixture of (B) ) in an electric oven at 450°C for 2 hours (containing 0.21% magnesium), (D) "Seto ほ ん じ お焼き硩" (pure Seto roasted salt) manufactured by Ajinomoto Co., Ltd. ) (containing 0.18% magnesium), (E) is an equal mixture of (A) and yeast extract with high content of glutathione (Torula yeast extract, product of Xingren Co., Ltd., containing 3% glutathione) (containing 0.03% glutathione), (F) is an equal mixture of (D) and yeast extract with high glutathione content. Then, re...

Embodiment 1

[0055] (Example 1) Example of the edible meat improving agent of the present invention

[0056] As the roasted salt, "Seto ほ ん じ お焼き硩" (pure Seto roasted salt) (containing 0.18% magnesium) produced by Ajinomoto Co., Ltd. was used. The Torula yeast extract (containing 3% glutathione) produced by the company uses "Amarutei MR" (maltitol) produced by Towa Chemical Industry Co., Ltd. as the sugar alcohol and Nitten "SG オリゴ" (SG oligomerization) produced by Chemical Co., Ltd., as an esterified starch derivative, used "Emalstar 30A" (Emulstar 30A) produced by Matsutani Chemical Co., Ltd., prepared as shown in Table 3. Edible meat improvers A to D (hereinafter referred to as improvers). At the same time, sugar alcohols and starch derivatives were removed from improver D, and this part was supplemented with dextrin to prepare reference products E, F, and G. Also, for ease of operation and comparative evaluation, the baking salt concentration is unified to 10%.

[0057] table 3

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com