Method for preparing pyroceram fibre

A technology of high temperature resistant ceramics and fibers, applied in the field of preparation of high temperature resistant ceramic fibers, can solve problems such as high cost, unfavorable promotion and application, complicated preparation methods, etc., and achieve reliable sources, good processability and physical properties, and simple processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

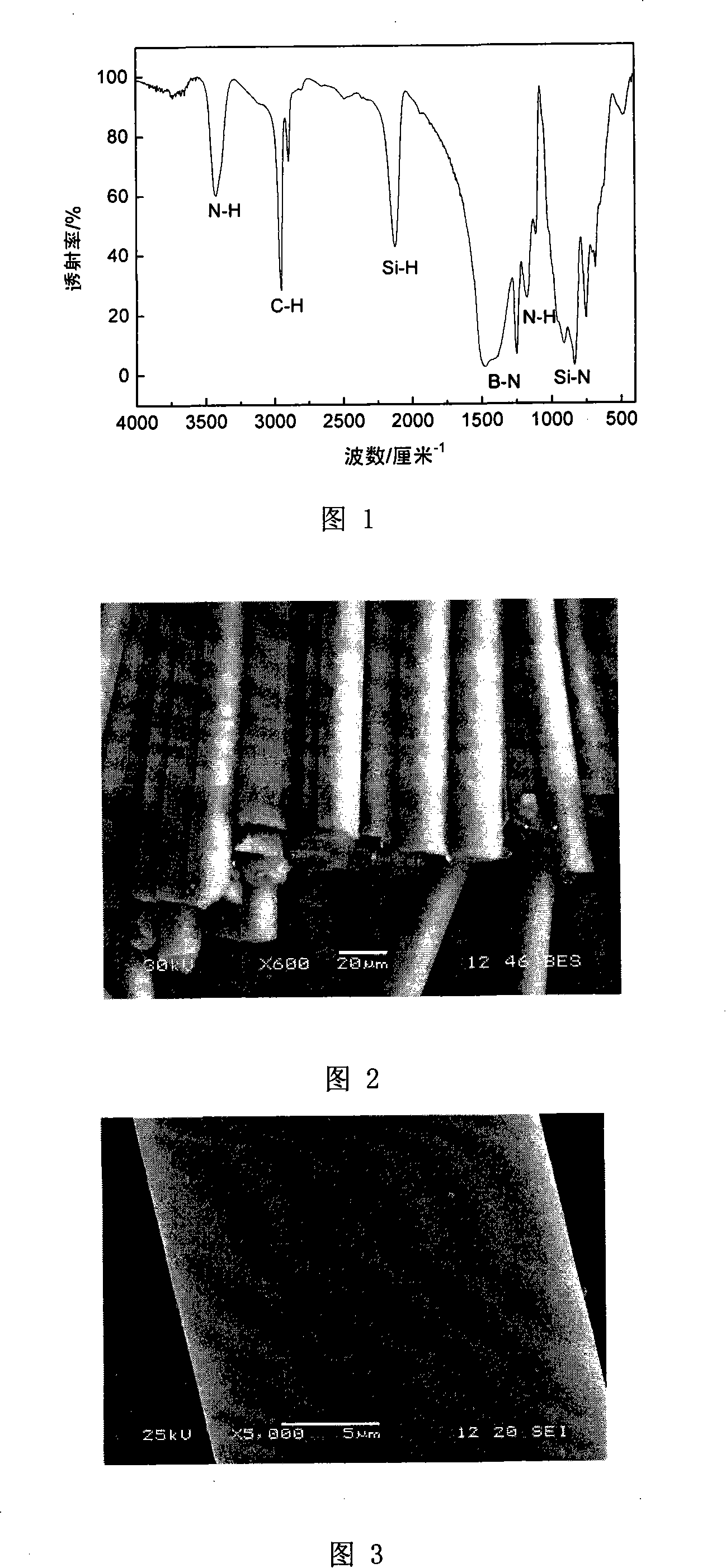

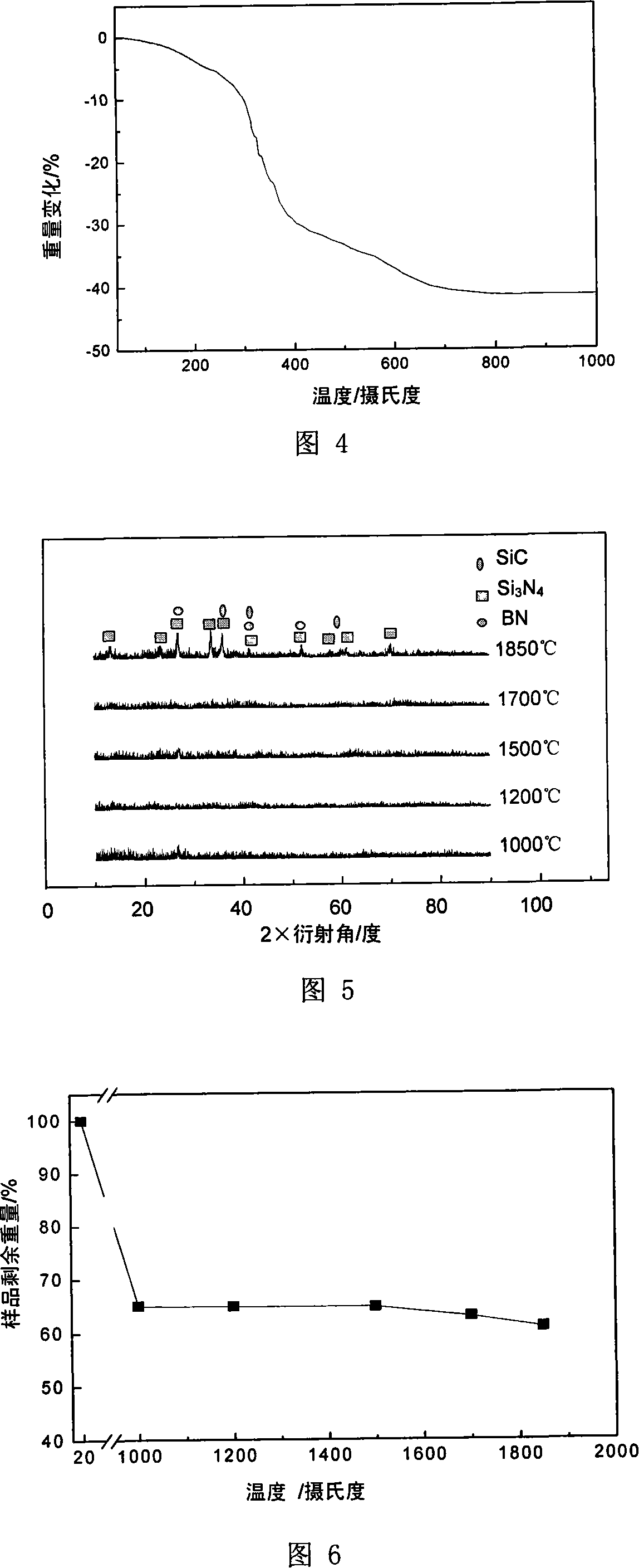

Embodiment 1

[0039](1) Repeatedly vacuumize the 250ml three-neck flask with electric stirring device in the reactor, and fill it with dry nitrogen at least three times to get rid of the air and moisture therein, and then pre-cool the reactor to minus 10 degrees; Hydrogen dichlorosilane 0.3mol (34.5g) and boron trichloride 0.15mol (17.6g) were successively injected into a three-necked flask protected by dry nitrogen, and methylamine with a purity of 99.999% was introduced into the reaction system while stirring, System heats up rapidly, and produces a large amount of precipitation, when temperature no longer raises, stops the feeding of methylamine; (3) when the temperature of the system is down to room temperature, the product obtained in step (2) is under the protection of dry nitrogen, Filter in the glove box; (4) take the filtrate in step (3) and carry out polymerization under the protection of dry nitrogen, the reactor temperature is 320 ° C, the cracking column temperature is 450 ° C, ...

Embodiment 2

[0044] (1) Same as Example 1; (2) Get 0.3mol (30.3g) of dichlorosilane and 0.1mol (11.7g) of boron trichloride into a three-necked flask protected by dry nitrogen successively with a syringe, and pass through while stirring Inject ammonia gas with a purity of 99.999% into the reaction system, the system heats up rapidly and produces a large amount of precipitation, when the temperature no longer rises, stop the introduction of ammonia gas; (3) when the temperature of the system drops to room temperature, the (2) The product obtained in step (2) is filtered in a nitrogen bag under the protection of dry nitrogen; (4) the filtrate in step (3) is polymerized under the protection of dry nitrogen, and the reactor temperature is 280 ° C. The column temperature is 410°C, keep it warm for 2 hours; (5) Reduce the system temperature to 200°C, distill under reduced pressure for 2 hours, remove the solvent and small molecules, and then cool down to room temperature to obtain a colorless and...

Embodiment 3

[0046] (1) Same as Example 1; (2) Get 0.3mol (38.7g) of dimethyl dichlorosilane with a syringe, and inject 0.2mol (16.5g) of dichloroborohydroane into a three-necked flask protected by dry nitrogen, While stirring, feed methylamine with a purity of 99.999% into the reaction system, the system heats up rapidly and produces a large amount of precipitation, when the temperature no longer rises, stop the feed of methylamine; (3) until the temperature of the system drops to At room temperature, the system product is filtered in a nitrogen bag; (4) the filtrate obtained in step (3) is placed in a reactor with a condenser tube, a cracking column, and a reflux device, and slowly heated under the protection of dry nitrogen Thermal polycondensation, the temperature of the reactor is 270°C, the temperature of the cracking column is 440°C, and the temperature is kept for 2 hours; (5) The temperature of the system is reduced to 300°C, and the vacuum distillation is carried out for 30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com