Epitaxy growth method for gallium antimonide on gallium arsenide substrate

A technology of epitaxial growth and gallium arsenide, applied in the field of epitaxial growth of gallium antimonide crystal, can solve the problems of rough surface, poor crystal quality and high dislocation density of GaSb material, and achieve the improvement of crystal quality, surface flatness, and smooth surface. The effect of increasing the degree of dislocation and decreasing the dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

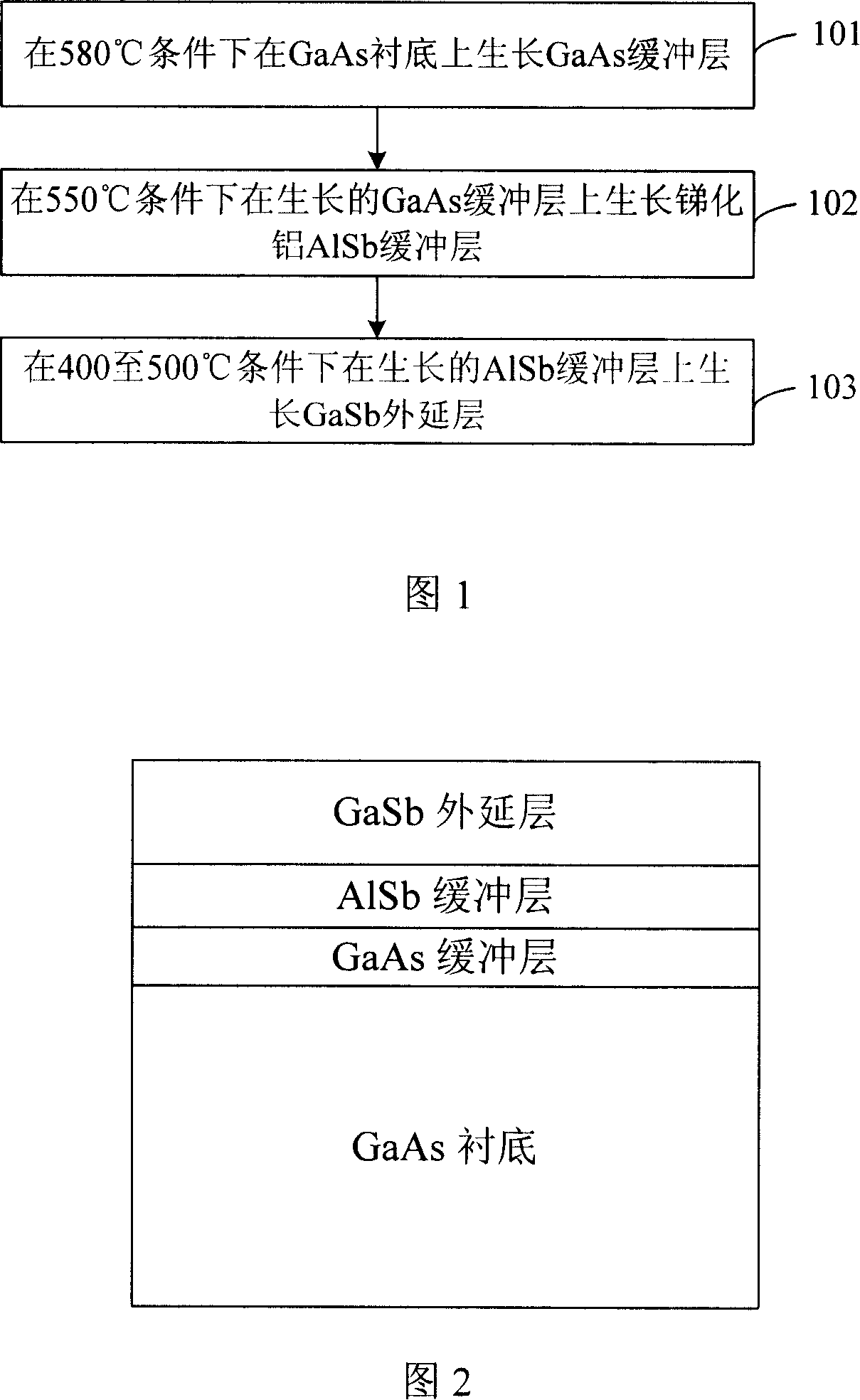

[0055] After high-temperature deoxidation and degassing of the cleaned GaAs substrate, the temperature of the GaAs substrate is lowered to 580°C, the Ga source furnace shutter is opened, the Ga source temperature is 1150°C, and the GaAs high-temperature buffer layer is crystallized on the GaAs substrate grow. The growth time of the GaAs buffer layer is 30 minutes, and the thickness is 0.5 μm.

[0056] Then close the Ga source furnace shutter, lower the substrate temperature to about 550°C, close the As source furnace shutter, open the Sb source furnace shutter, open the Al source furnace shutter, the Al source temperature is 1180°C, and grow a low-temperature AlSb buffer on the GaAs buffer layer. layer, the growth time is 12 minutes, and the thickness is about 100nm.

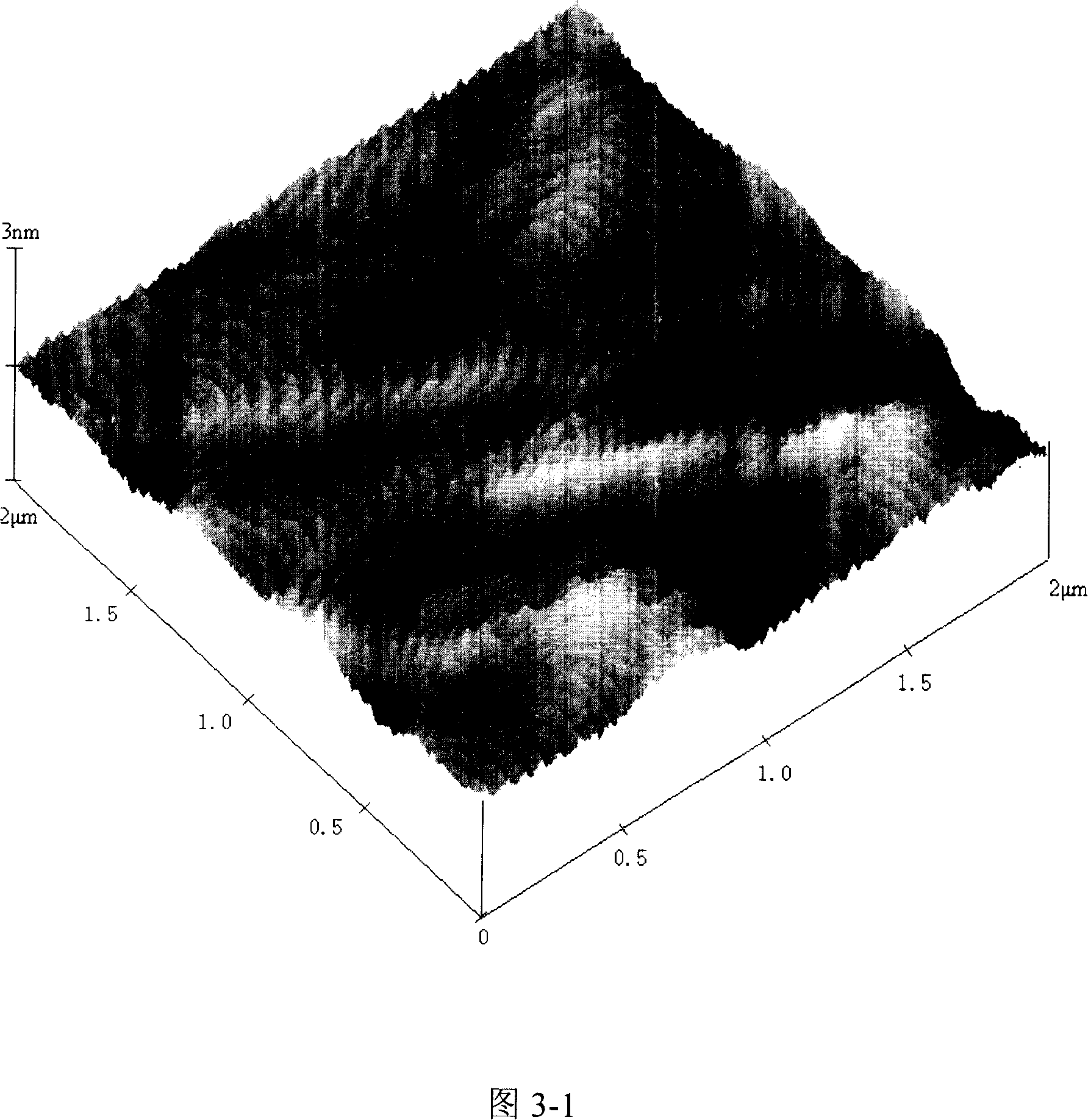

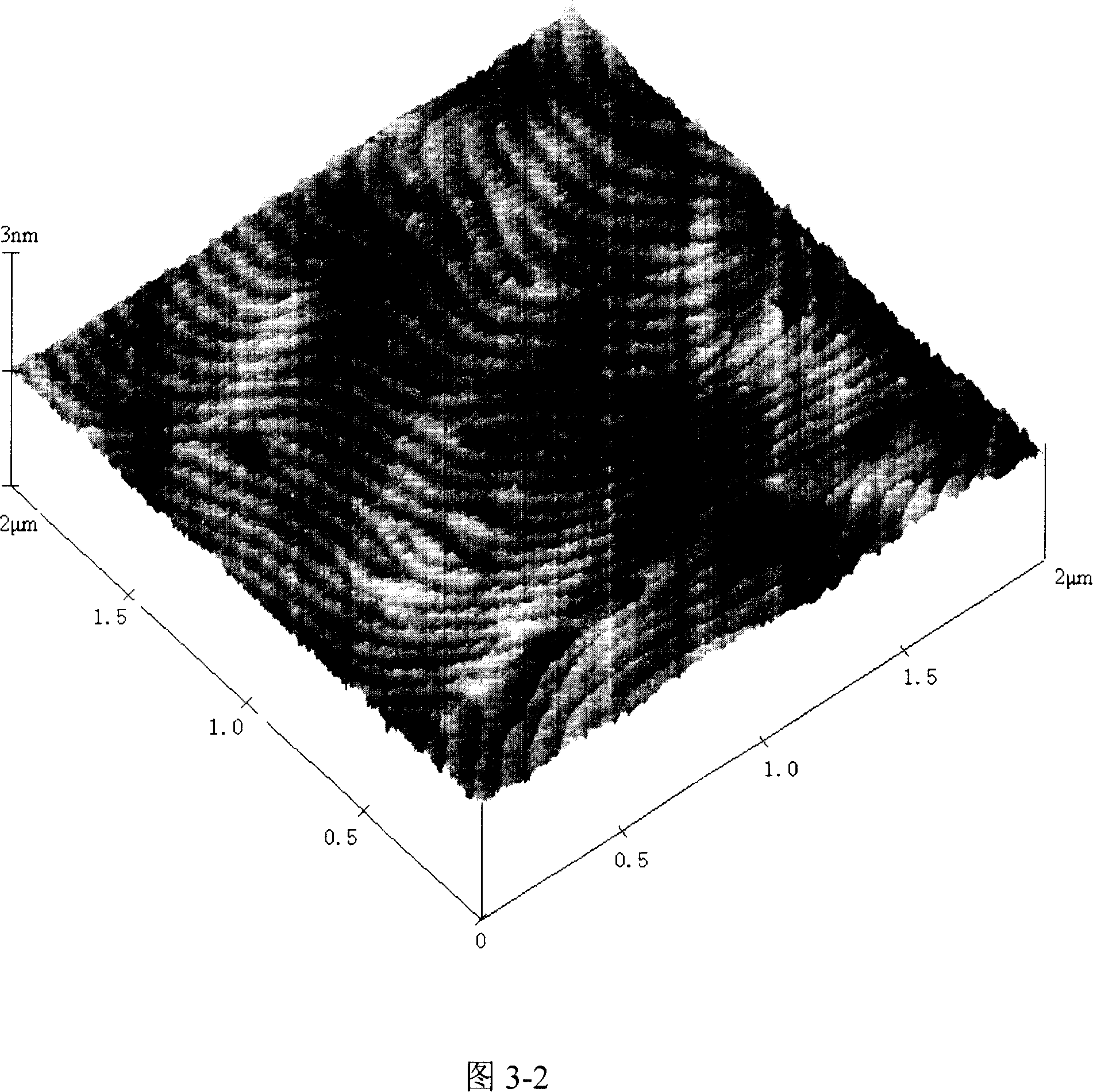

[0057] Then close the shutter of the Al source furnace, lower the substrate temperature to 500°C, open the shutter of the Ga source furnace, and grow the epitaxial layer GaSb on the AlSb buffer layer. The surfa...

Embodiment 2、3

[0059] The epitaxial layer growth temperatures at lower temperatures were 460° C. and 480° C., and the rest were the same as in Example 1. The surface roughness measured by the atomic force microscope and the FWHM value measured by the DCXRD rocking curve are listed in Table 1.

[0060] Example

[0061] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com