Chitosan/starch blending medicine-carrying fibre, preparation method and use thereof

A technology of chitosan and starch, which is applied in the fields of fiber chemical characteristics, medical science, textiles and papermaking, etc., can solve the problems of unsatisfactory comprehensive performance of pure chitosan fiber, achieve excellent drug release performance, rich raw material sources, excellent The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

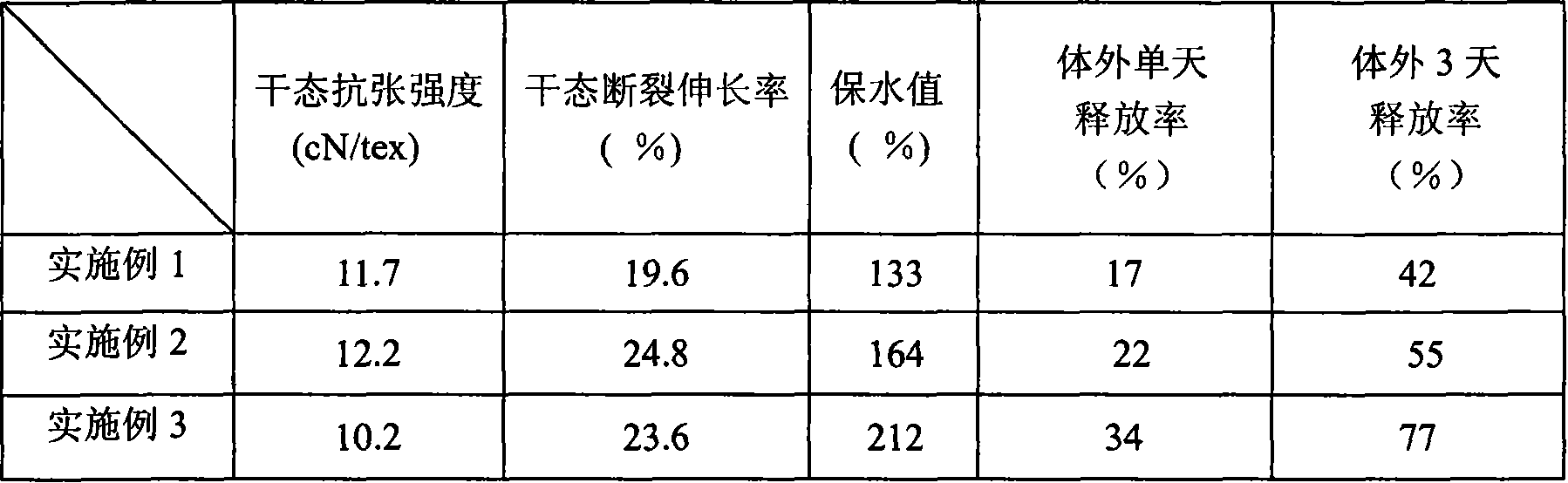

Embodiment 1

[0010] Embodiment 1: The degree of deacetylation of 45g is 87%, and the viscosity-average molecular weight is 8.0×10 5 Chitosan is dissolved in 900ml of 2% (mass ratio) acetic acid solution to obtain chitosan solution; 5g of starch is dissolved in 100ml of distilled water to obtain starch solution. The above two solutions are fully mixed with 4g salicylic acid, filtered, and after degassing under reduced pressure, the aqueous solution of sodium tripolyphosphate (mass ratio) and absolute ethanol are mixed in a ratio of 4:6 to 6 to form 5% to 10%. The mixed liquid mixed in the ratio of :4 is a coagulation liquid, and the chitosan / starch drug-loaded fiber is prepared by solution spinning at room temperature, and the obtained fiber elongation rate is 20%. Its mechanical properties, water retention value and release performance are listed in Table 1.

Embodiment 2

[0011] Embodiment 2: Get 35g chitosan and dissolve in the acetic acid solution of 700ml 2% (mass ratio) to obtain chitosan solution; Get 15g starch and dissolve in 300ml distilled water to obtain starch solution. The above two solutions are fully mixed with 4g salicylic acid, filtered, and after degassing under reduced pressure, the aqueous solution of sodium tripolyphosphate (mass ratio) and absolute ethanol are mixed in a ratio of 4:6 to 6 to form 5% to 10%. The mixed liquid mixed in the ratio of :4 is a coagulation liquid, and the chitosan / starch drug-loaded fiber is prepared by solution spinning at room temperature, and the obtained fiber elongation rate is 20%. Its mechanical properties, water retention value and release performance are listed in Table 1.

Embodiment 3

[0012] Embodiment 3: Get 25g chitosan and dissolve in the acetic acid solution of 500ml 2% (mass ratio) to obtain chitosan solution; Get 25g starch and dissolve in 500ml distilled water to obtain starch solution. The above two solutions are fully mixed with 4g salicylic acid, filtered, and after degassing under reduced pressure, the aqueous solution of sodium tripolyphosphate (mass ratio) and absolute ethanol are mixed in a ratio of 4:6 to 6 to form 5% to 10%. The mixed liquid mixed in the ratio of :4 is a coagulation liquid, and the chitosan / starch drug-loaded fiber is prepared by solution spinning at room temperature, and the obtained fiber elongation rate is 20%. Its mechanical properties, water retention value and release performance are listed in Table 1.

[0013] The solution spinning method used in the above examples is a prior art, which has been described in detail in the existing literature, so the solution spinning method will not be repeated in each embodiment.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com