Nano antimicrobial powder body with shell powder as carrier and method for preparing the same

A technology of nano-antibacterial powder and shell powder, which is applied in the field of nano-materials, can solve the problems of affecting material performance and processing performance, high price of nano-silver antibacterial products, and poor antibacterial durability of materials, so as to achieve good compatibility and great environmental protection significance , High antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

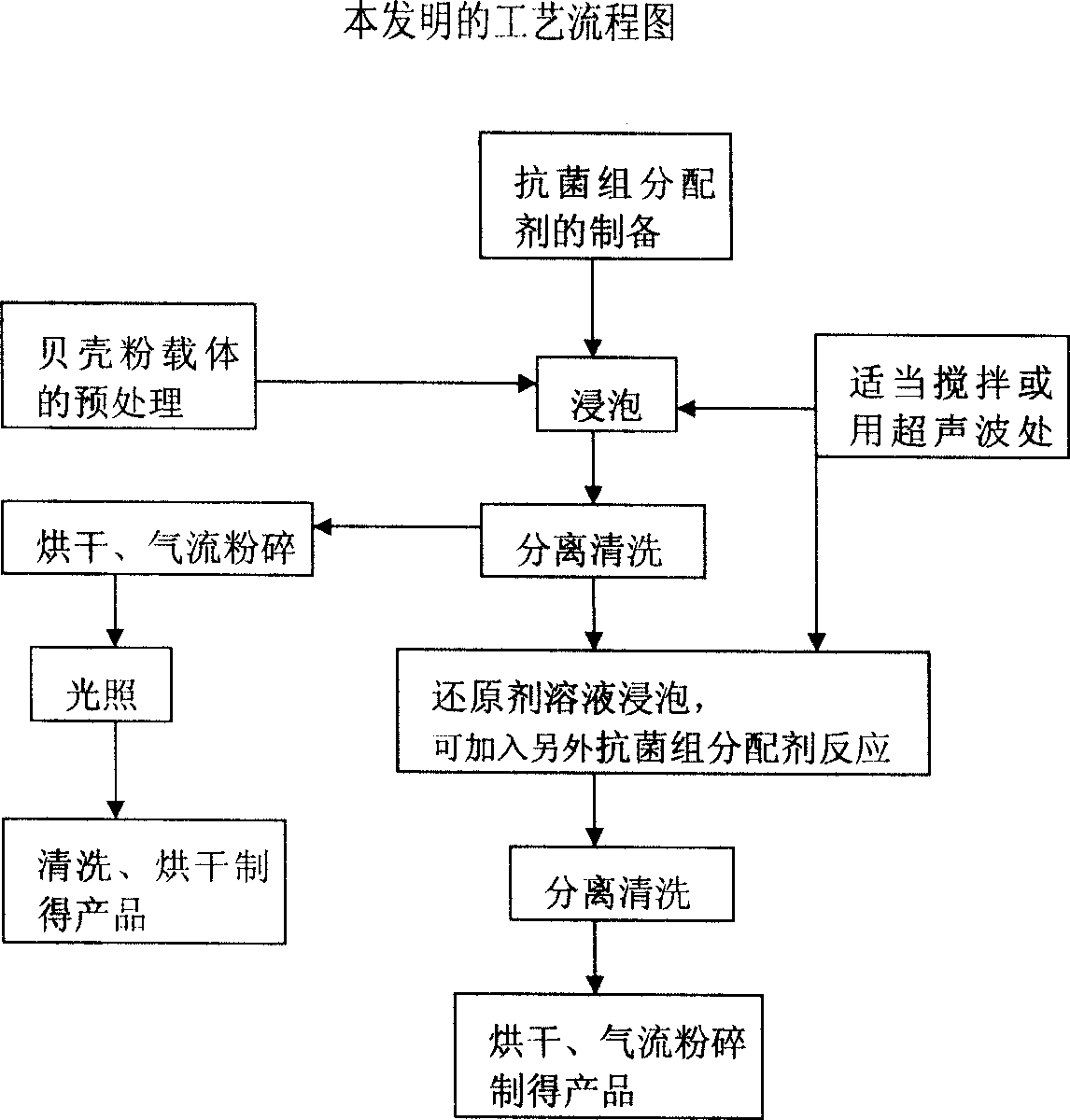

Method used

Image

Examples

Embodiment 1

[0021] (1), weigh 0.102gAgNO 3 , dissolved in 100ml deionized water to obtain a concentration of 0.006mol L -1 AgNO 3 solution; (2), take by weighing 2.0g dry oyster shell powder, put into AgNO 3 Soak in the solution, stir properly or use ultrasonic treatment with a frequency of 40kHz to soak the oyster shell powder thoroughly; (3), centrifuge to separate AgNO 3 solution and oyster shell powder, decanting the upper AgNO 3 After the solution, immediately add an appropriate amount of deionized water, shake well and then centrifuge immediately. The cleaning process should be fast in this way, so as to avoid the AgNO adsorbed in the oyster shell powder 3 Eluted out; (4), dry the sample obtained from the above separation at about 80-100°C (spray drying can be used in batches); (5), crush the dried sample with an appropriate air flow; (6), dry the sample Place it thinly in the container, irradiate the sample with sunlight for 30-60min, during the illumination process, properly t...

Embodiment 2

[0023] (1) Weigh 0.102g AgNO 3 , dissolved in 100ml deionized water to obtain a concentration of 0.006 mol L -1 AgNO 3 solution; (2), take by weighing 2.0g dry oyster shell powder, put into AgNO 3 Soak in the solution, stir properly or use ultrasonic treatment with a frequency of 40kHz to thoroughly soak the oyster shell powder; (3), separate AgNO 3 solution and oyster shell powder, decanting the upper AgNO 3 After the solution, immediately add an appropriate amount of deionized water, shake well and then centrifuge immediately, and then wash it again with deionized water according to this method. The cleaning process should be fast to avoid the AgNO adsorbed in the oyster shell powder. 3 Wash it out; (4), add appropriate amount of formaldehyde to soak the sample, and the soaking time is about 1 hour, and the formaldehyde makes the AgNO adsorbed in the oyster shell powder 3 Ag in + Reduction to form nano-silver particles; (5), centrifugation is used again, and the sample ...

Embodiment 3

[0025] Mix the oyster shell powder carrier into 1L of 20% suspension, add 1.4mol·L -1 Silver nitrate aqueous solution 80ml, stirred at 60°C or treated with ultrasonic waves with a frequency of 40kHz for 1-3 hours, then added 1mol L -1 The reducing agent oxalic acid solution is 30-100mL, reacted at 60-80°C for 2-3 hours, the product is washed, dried and jet-pulverized to prepare the nano antibacterial powder of the present invention, and then sealed and stored. The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com