Light emitting diode chip and method for manufacturing same

A light-emitting diode and chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as high working voltage, high contact resistance of metal electrode layers, and high requirements for uniform distribution, so as to reduce working voltage and improve current distribution Situation, effect of improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

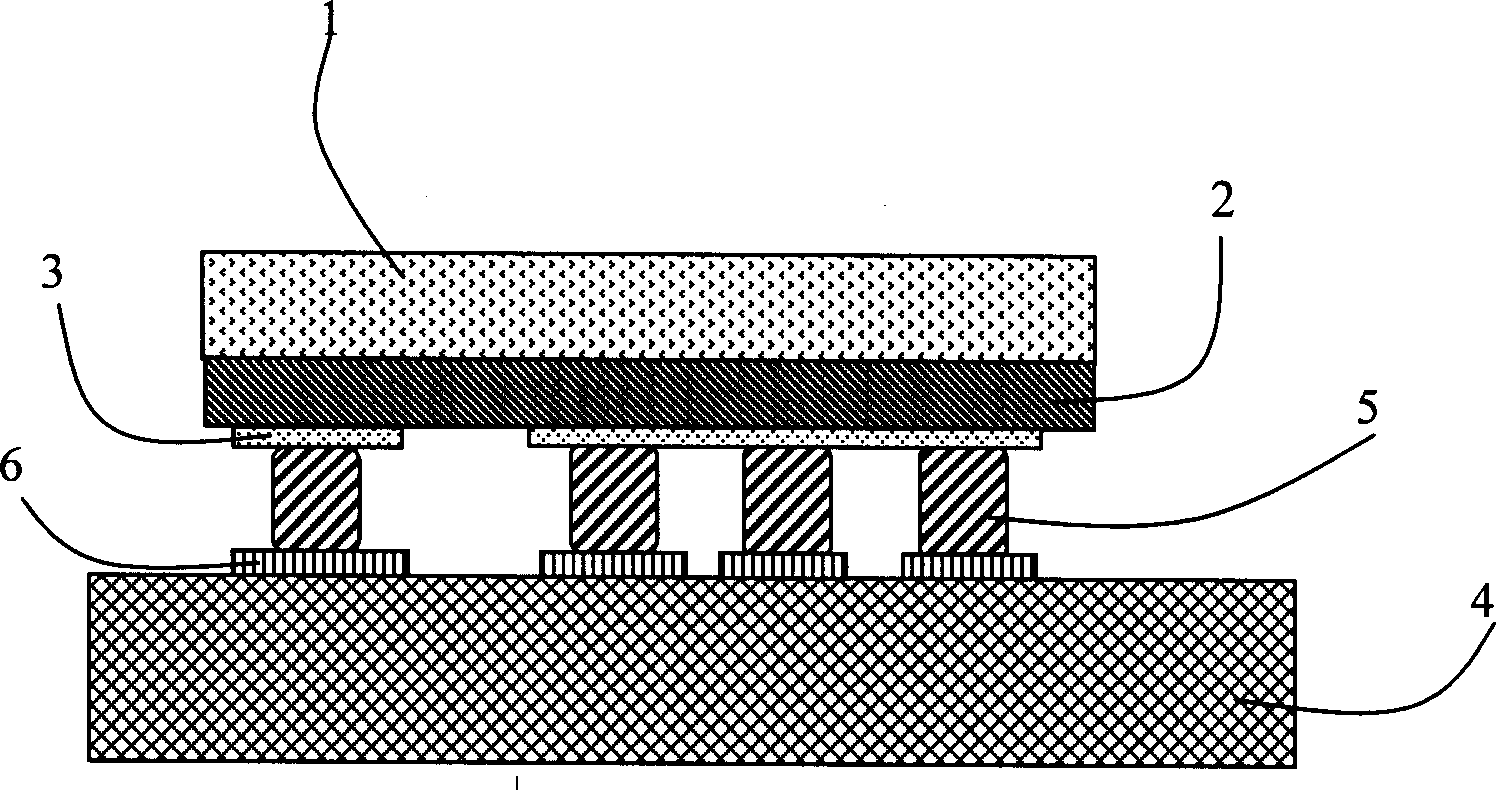

[0038] In this embodiment, a GaN-based epitaxial wafer grown on a transparent aluminum oxide single crystal (ie, a sapphire substrate Sapphire) is used to prepare LED chips for flip-chip bonding. The process is as follows Figure 3a to 3c As shown, the LED chip and its manufacturing process in this embodiment are now specifically described as follows:

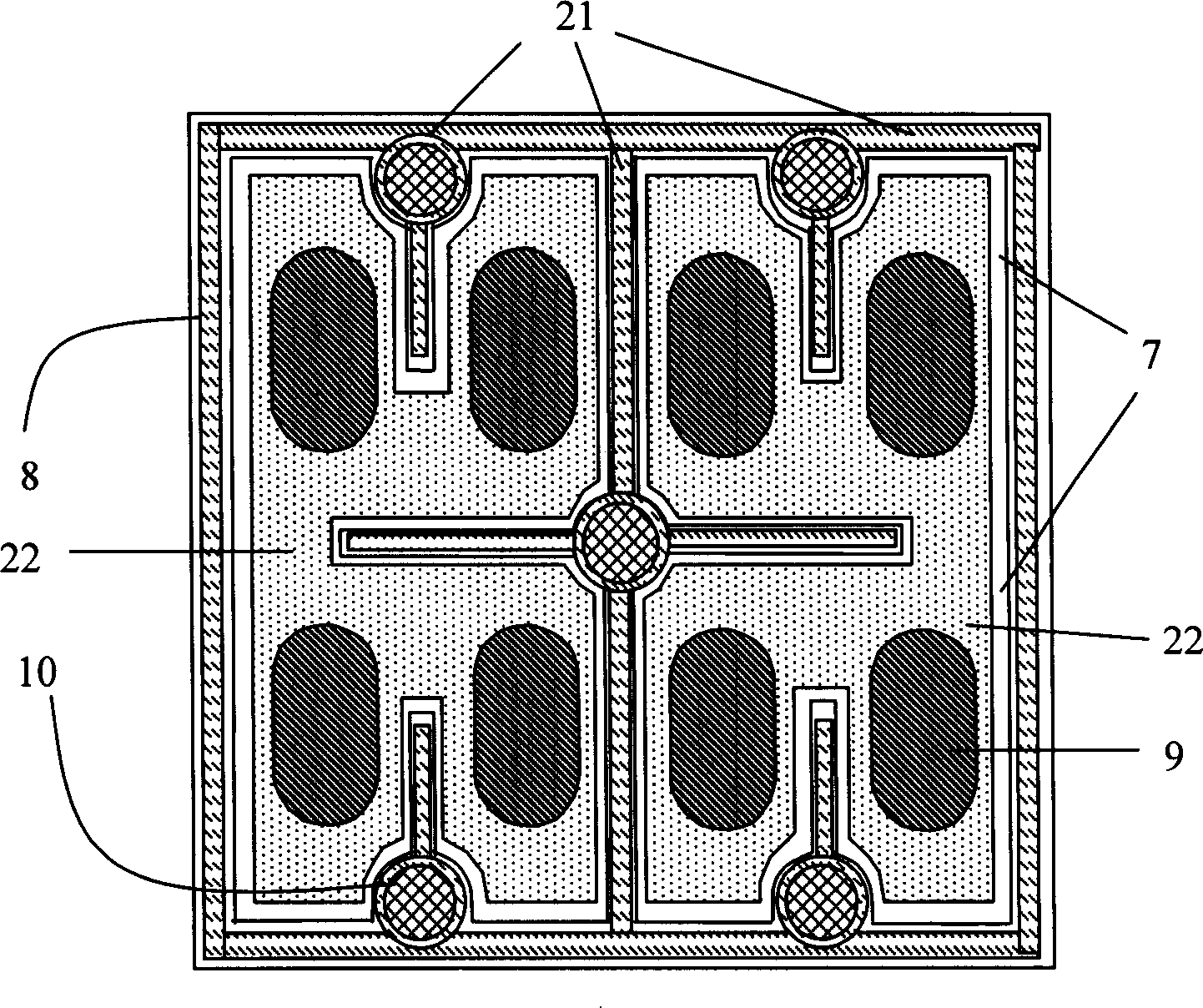

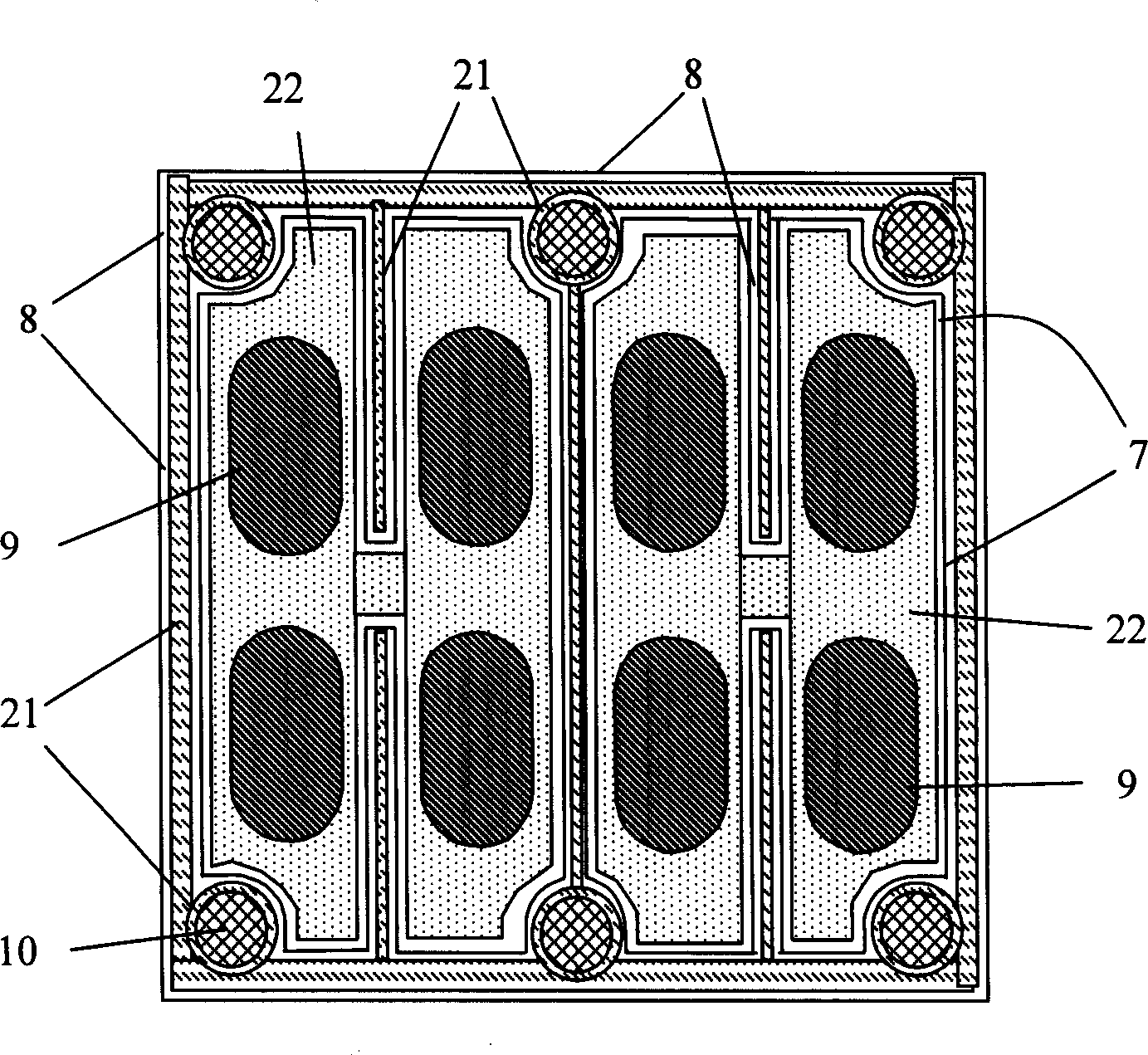

[0039] First, grow a GaN epitaxial wafer on a sapphire substrate 1. According to the design pattern and size of the P-type and N-type regions, an etching process is used to form the P-type region 7 and the N-type region 8 required by the design. Figure 3a Shown. Those skilled in the art can understand that the design graphics conforming to the concept of the present invention can have many variations, for example, Figure 2a to 2g Seven graphic designs conforming to the inventive concept are shown in. The photolithography mask in the etching process can be made according to relevant parameters and design patterns.

[0040] Next, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com