Ethane oligomerization and polymeric chromium catalyst and preparation method thereof

A catalyst, the technology of ethoxycarbonylpyridine chromium halide, is applied in the field of N-N-O tridentate ligand chromium complex catalyst, which can solve the problem of no model compound, limited ethylene oligomerization and polymerization industrial development, active center and mechanism are not confirmed, etc. problem, to achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

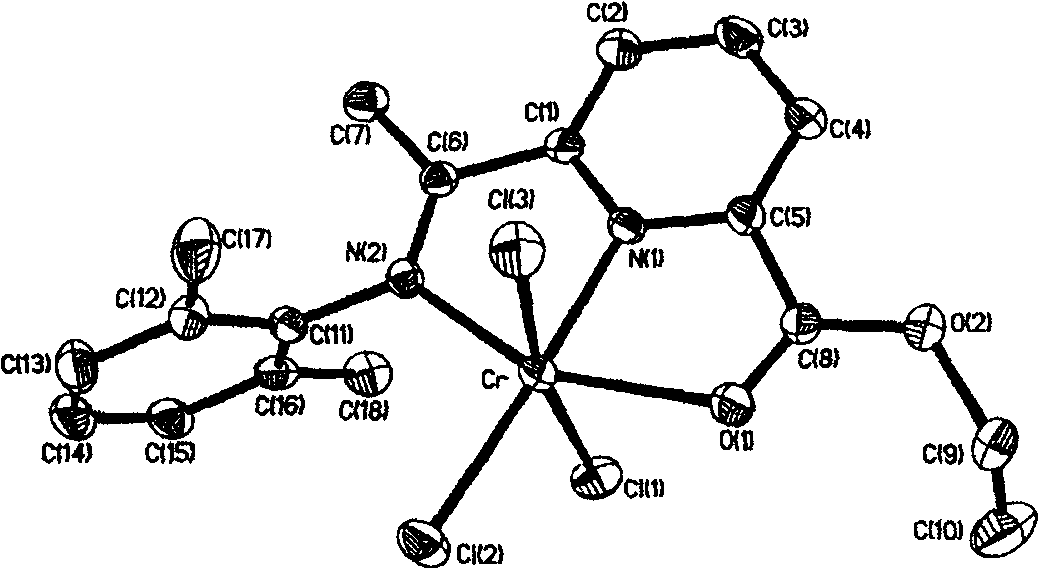

[0046] 1. The preparation of catalyst C1: Chromium tetrahydrofuran chloride (0.372g, 1mmol) and corresponding 6-ester group-2-iminopyridine L1 (0.296g, 1mmol) are added in the Schlenk bottle, and the logical N 2 After three replacements, add treated dichloromethane (10ml), stir at room temperature for 24 hours, add anhydrous diethyl ether after concentration, a green precipitate precipitates, after filtration, vacuum-dry to obtain the complex (0.390g, 0.86mmol), C1 yield: 86%. Elemental Analysis Theoretical Value C 18 h 20 Cl 3 CrN 2 o 2 : C, 47.54; H, 4.43; N, 6.16. Found: C, 47.44; H, 4.60; N, 6.33%. IR(KBr:cm -1 ): 1642; 1587; 1467; 1407; 1381; 1341; 1291; 1217; 1097; 992; 851; 768cm -1 .

[0047] 2. Ethylene polymerization: Dry the 250ml polymerization bottle equipped with a magnetic stirrer at 130°C for 6 hours continuously, vacuumize it while it is hot and use N 2 Air replacement 3 times. Catalyst C1 (2.3 mg, 5 μmol) was added, followed by evacuation and replac...

Embodiment 2

[0049] 1. The preparation of catalyst C1 is the same as in Example 1.

[0050] 2. Ethylene polymerization: Vacuumize a 250 ml stainless steel kettle equipped with a mechanical stirrer and a thermocouple, replace it with nitrogen for 3 times, and then replace it with ethylene for 2 times. After cooling to 25°C, add the toluene solution of catalyst C1 (2.3 mg, 5 μmol) and a certain amount of toluene in sequence, and finally add a certain amount of ethylaluminum dichloride (1mol / L, 5ml) to make Al / Cr=1000, The total volume of toluene was 100 mL. The ethylene pressure was immediately raised to 10 atm and stirred vigorously at 25°C for 30 minutes. After cooling, take out a little reaction solution, neutralize the MAO in it with dilute hydrochloric acid at 0°C, take a small amount of toluene layer, dry it with anhydrous sodium sulfate, and measure the content and distribution of oligomers by gas chromatography. As a result, no oligomers were formed. Pour the remaining reaction so...

Embodiment 3

[0052] 1. The preparation of catalyst C1 is the same as in Example 1.

[0053] 2. Ethylene polymerization: Dry the 250ml polymerization bottle equipped with a magnetic stirrer at 130°C for 6 hours continuously, vacuumize it while it is hot and use N 2 Air replacement 3 times. Catalyst C1 (2.3 mg, 5 μmol) was added, followed by evacuation and replacement with ethylene twice. A certain amount of toluene (29.6ml) was injected with a syringe, and a hexane solution of diethylaluminum chloride (0.375ml) was added. Make Al / Cr = 150, keep the ethylene pressure of 1 atm at 25°C, and stir vigorously for 30 minutes. Add 5% hydrochloric acid ethanol solution to the reaction solution for neutralization, and a white solid precipitates out. But the amount is so small that it cannot be filtered out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com