Sol gel functionalized silicate catalyst and scavenger

A catalyst, silicate technology, applied in physical/chemical process catalysts, molecular sieve catalysts, catalyst activation/preparation, etc., can solve problems such as economic infeasibility, metal removal, product loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

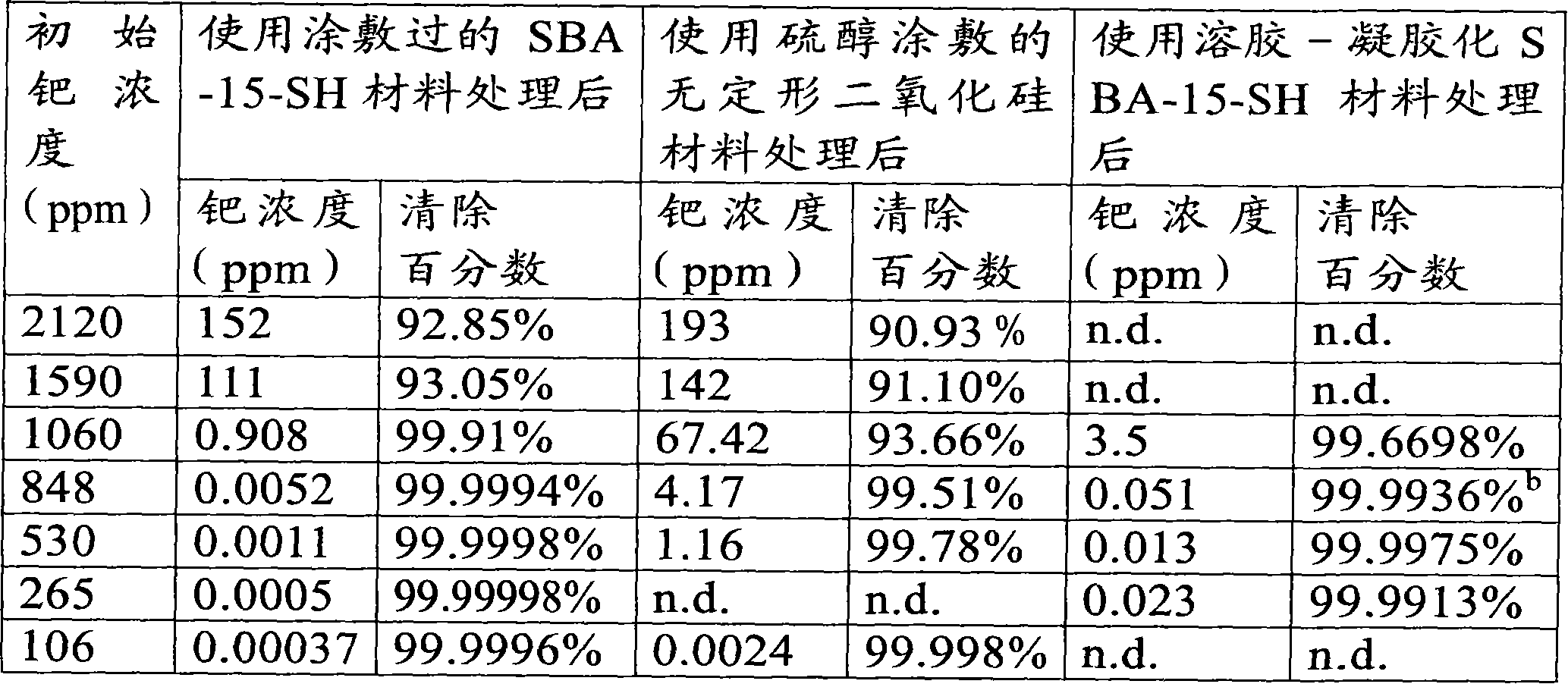

[0205] Example 1. Preparation of coated SBA-15-SH material

[0206] To a suspension of SBA-15 suspended in anhydrous toluene (30 mL) or silica (1 g) was added dropwise (CH 3 O)Si(CH 2 ) 3 SH (1 mL, 5.3 mmol) and pyrimidine (1 mL, 12.3 mmol) (see Zhao et al., 1998 a and b). The reaction mixture was refluxed at 115°C for 24 hours. After cooling, the suspension was filtered and the solid residue was washed with methanol, ether, acetone and hexane to remove unreacted thiol. The washed solid was vacuum dried at room temperature to obtain a white powder. The Brauner Emmer Teller (BET) surface area (specific surface area) of SBA-15-SH is 410 m2 / g, and the sulfur content obtained through elemental analysis is 2.2 mmol / g, SiO 2 The BET surface area (specific surface area) of -SH is 297 m2 / g, and the sulfur content obtained by elemental analysis is 1.3 mmol / g.

Embodiment 2

[0207] Embodiment 2. Preparation of sol-gel SBA-15-SH material

[0208] Synthesis of SBA-15 material functionalized with 3-mercaptopropyltrimethoxysilane (MPTMS) versus pure silica form SBA-15 (see articles a and b published in 1998 by Zhao et al. ) is similar, only changes in the amount of mercaptopropyltrimethoxysilane (MPTMS), as can be seen in the article published in 2002 by Melero et al. Using a one-step method, tetraethyl orthosilicate (TEOS) was co-condensed with different proportions of mercaptopropyltrimethoxysilane (MPTMS) to synthesize samples, wherein the mercaptopropyltrimethoxysilane (MPTMS) was prepared in three Block copolymer polyethylene oxide 123 (P123, with EO 20 PO 70 EO 20 (Aldrich) premixed in the presence of the general chemical formula in which EO stands for ethylene oxide and PO stands for propylene oxide). Use 4 grams of P123, 120 milliliters of 2M hydrochloric acid, 30 milliliters of distilled water, with different ratios of orthoethyl silica...

Embodiment 3

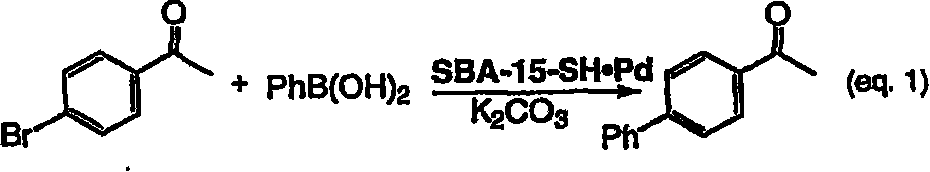

[0209] The preparation of embodiment 3.SBA-15-SH Pd material

[0210] Under an inert gas atmosphere, place 50 mL of 0.05 M Pd(OAc) in a Schlenk flask 2 Soluble in anhydrous tetrahydrofuran (THF) solution. Add 1 gram of SBA-15-SH or SiO to the solution 2 -SH, the mixture was stirred at room temperature for 1 hour. Then the solid catalyst was obtained by filtration, washed with tetrahydrofuran, and then vacuum-dried at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com