Method for producing petal shaped nano-magnesia by using rhomb spar

A nano-magnesium oxide and petal-shaped technology, applied in the direction of magnesium oxide, etc., can solve the problems of low product purity and extraction rate, low comprehensive resource utilization rate, and unsatisfactory parameter control, and achieve low production cost and high added value , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

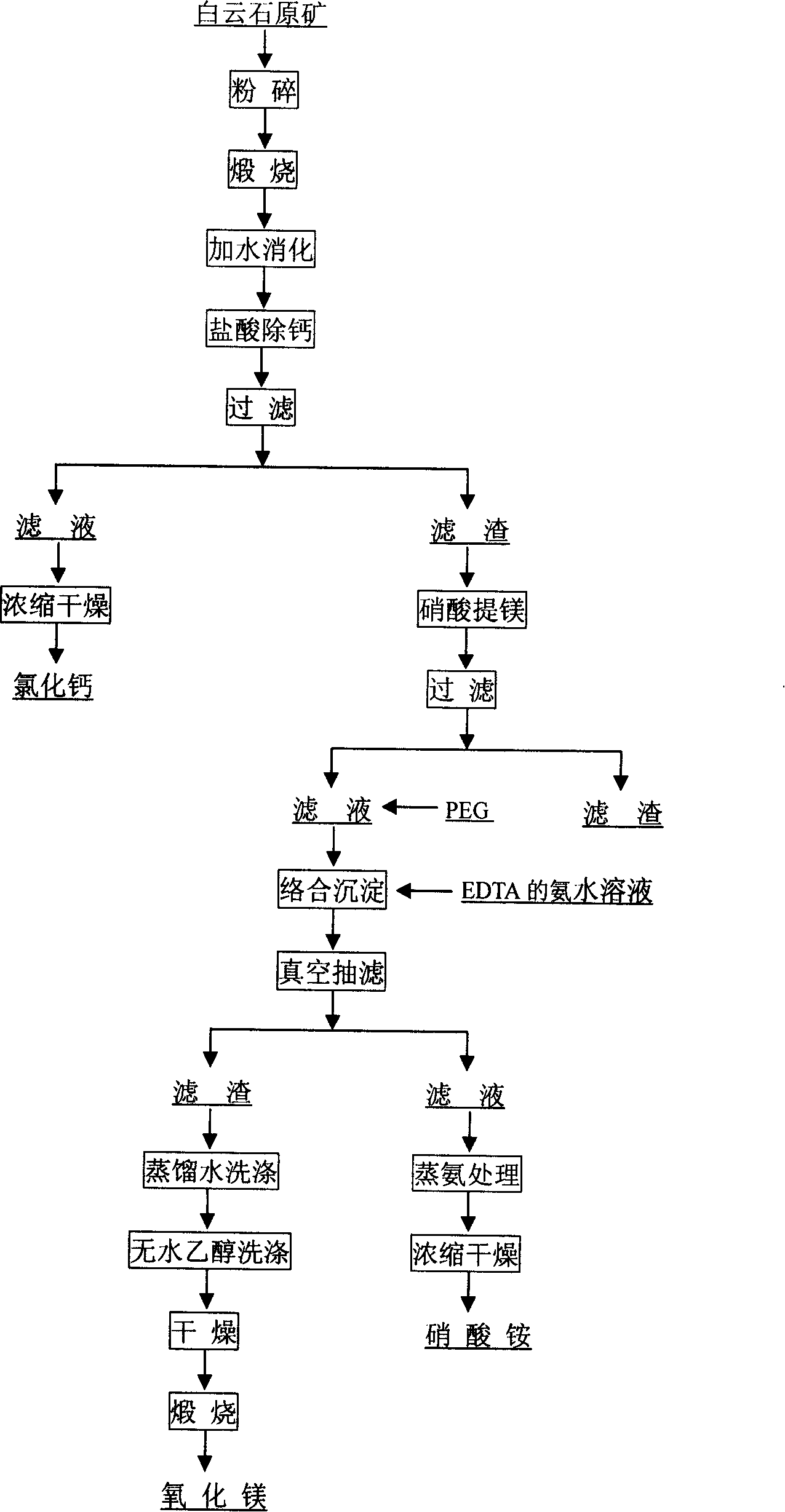

Method used

Image

Examples

Embodiment 1

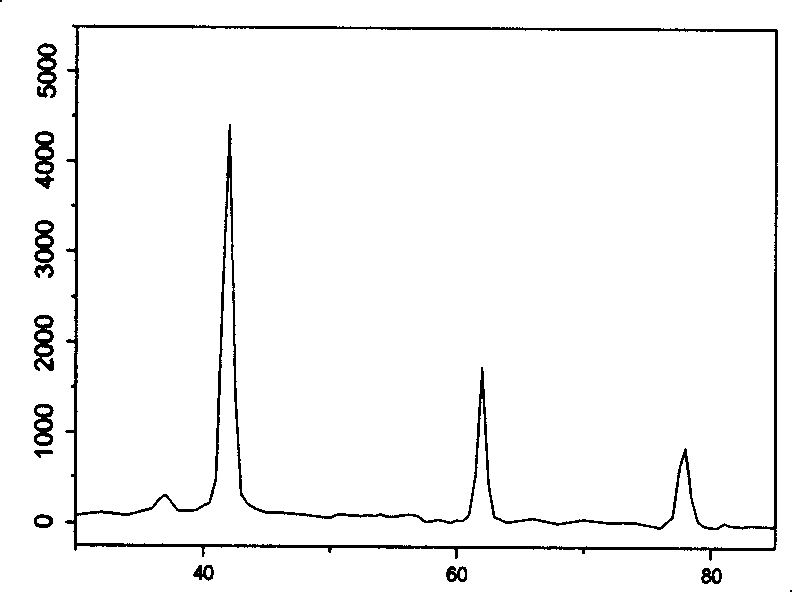

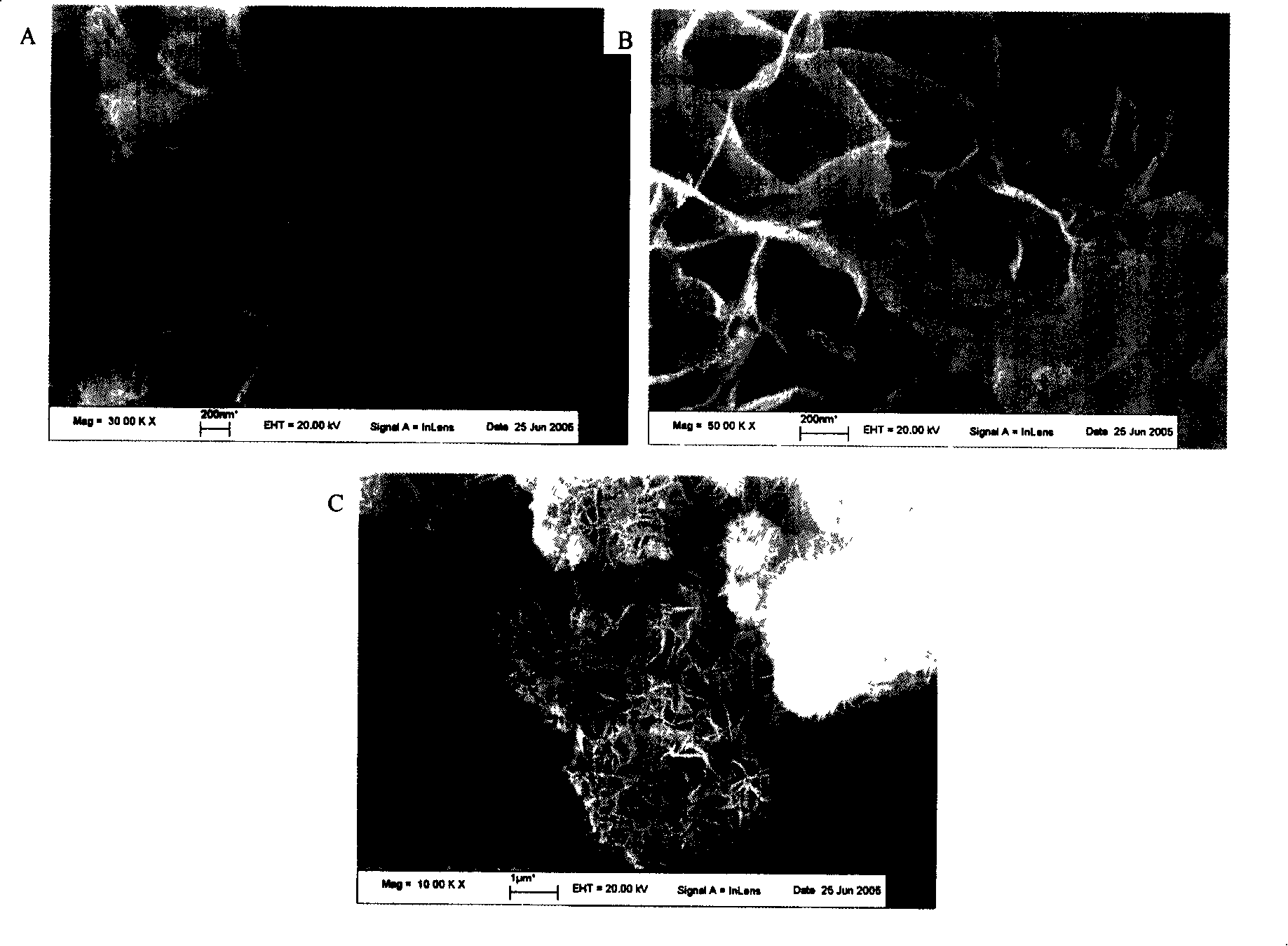

[0023] Embodiment 1: configure 25% (w / w) hydrochloric acid solution, 25% (w / w) nitric acid solution, 35% (w / w) ammonia solution, with molar ratio 0.1: 1 (nEDTA: nNH 3 ) Add EDTA powder into this ammonia solution to form complex precipitation agent A. Crush 200g of dolomite into 100 mesh and calcinate at 1100°C for 2h to form dolomite lime, add 300mL of tap water to make a mixture B with a solid-to-liquid ratio of 1:1, then mechanically stir and digest at 50°C for 1h to obtain clinker B. Drop in a hydrochloric acid solution with a molar ratio of 2.1:1 (nHCl:nCaO) at a certain rate until the pH changes from 14 to 6-7, filter and wash several times, and the filtrate is concentrated and dried to obtain a 98.86% purity CaCl 2 White powder. The filter cake was dispersed in 300mL tap water, and was added dropwise under mechanical stirring with a molar ratio of 2.1:1 (nHNO 3 : nMgO) nitric acid solution, stop when the system turns into a reddish-gray turbid liquid with a pH of abou...

Embodiment 2

[0024] Example 2: Dolomite ore was calcined at 850° C. for 3 hours, and the remaining conditions were the same as in Example 1 to obtain high-purity nano-MgO.

Embodiment 3

[0025] Example 3: 400 mL of tap water was digested with mechanical stirring at 80° C. for 20 minutes, and the remaining conditions were the same as in Example 1 to obtain high-purity nano-MgO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com