Waste lubricant oil recovery utilization method

A waste lubricating oil, hydrogen-oil ratio technology, applied in the direction of lubricating compositions, etc., can solve the problem of not completely removing metal impurities in waste lubricating oil, not improving the yield of lubricating oil base oil, and not proposing the environment Friendly recovery technology and other issues, to achieve the effect of optimizing hydrofining effect, high catalyst utilization rate, improving processing capacity and device yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

[0027] Select a used waste gear oil. After long-term use, wear, corrosion and oxidation, etc., the main physical and chemical properties have changed greatly, which seriously affects the use of lubricating oil. The raw material properties of waste lubricating oil are shown in Table 1. :

[0028] Table 1 Basic properties of waste gear oil raw materials

[0029] nature

[0030] Neutralization value, mgKOH / g

[0031] It can be seen from the properties in the table that the viscosity, chroma, S, N, and CCR of this waste gear oil are relatively high, and the water content and oxidation stability are particularly high, which shows that the degree of oxidation of this gear oil is very deep; from mechanical impurities In terms of metals, Ca, Zn, Mg, Na, Fe, and Mn are quite high, and Mo, Cu, and Pb are also high, indicating that the wear and corrosion of mechanical parts during use is also very serious, and the additives added are also very high. It has been corro...

Embodiment 3~5

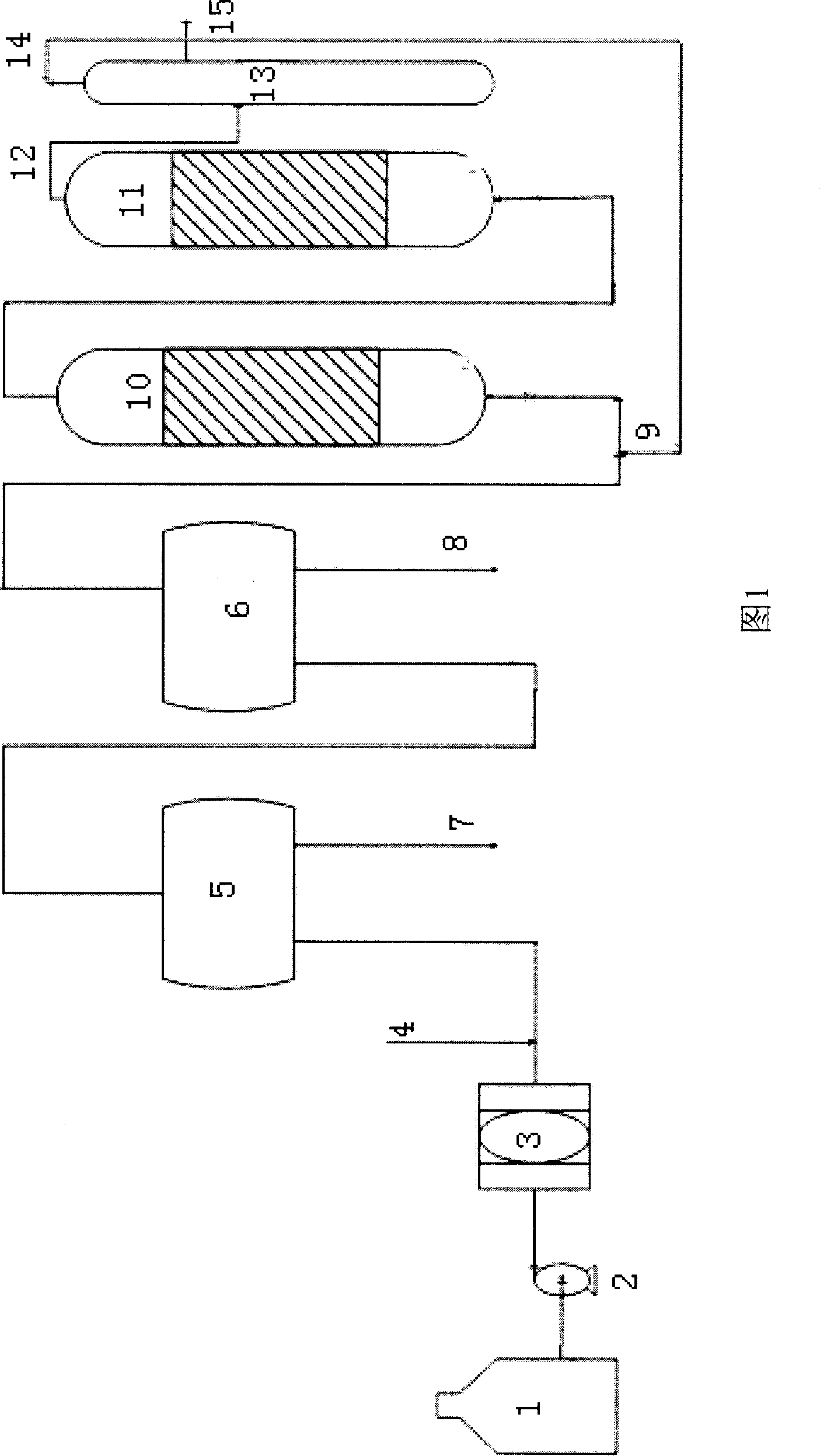

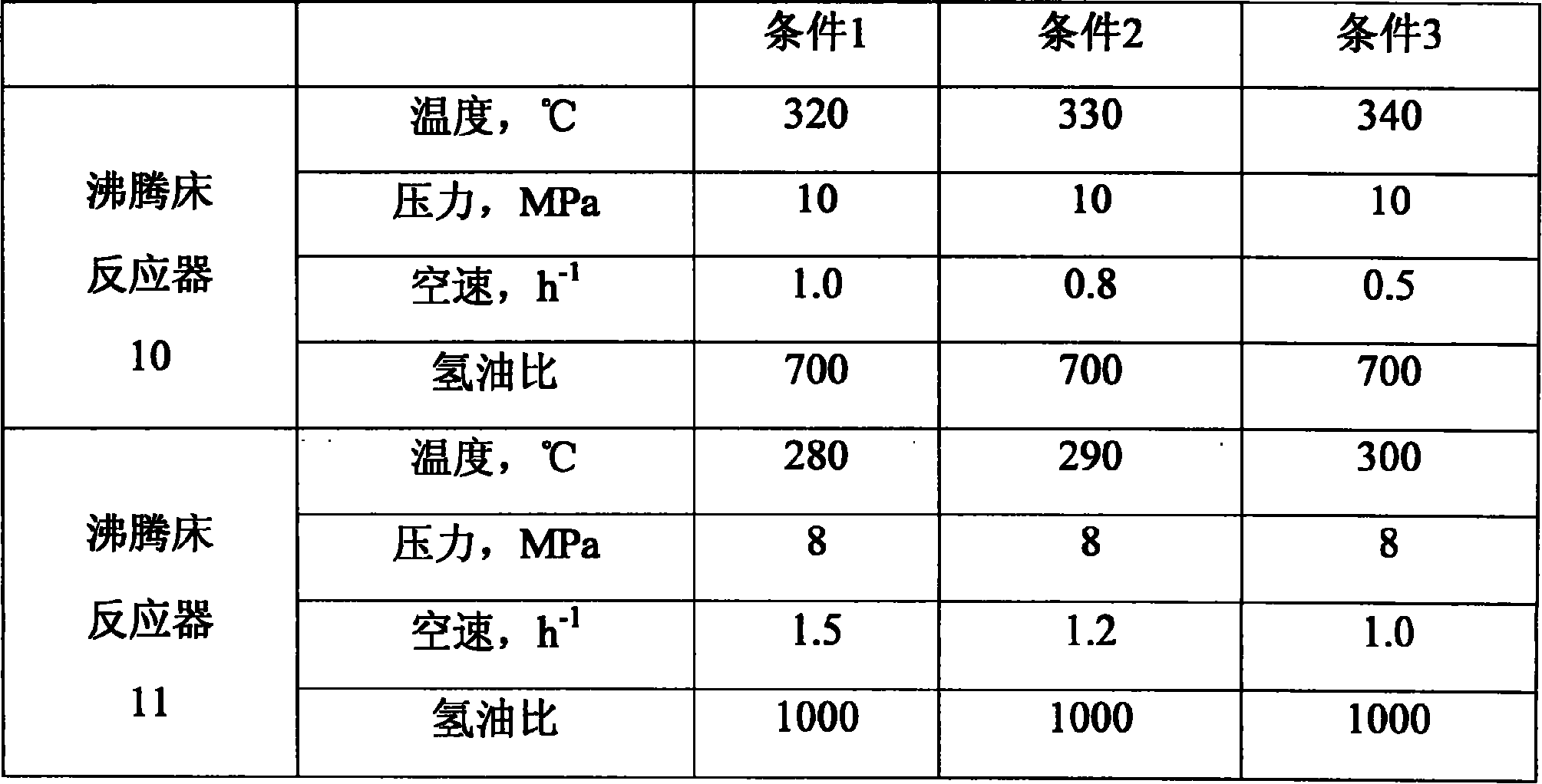

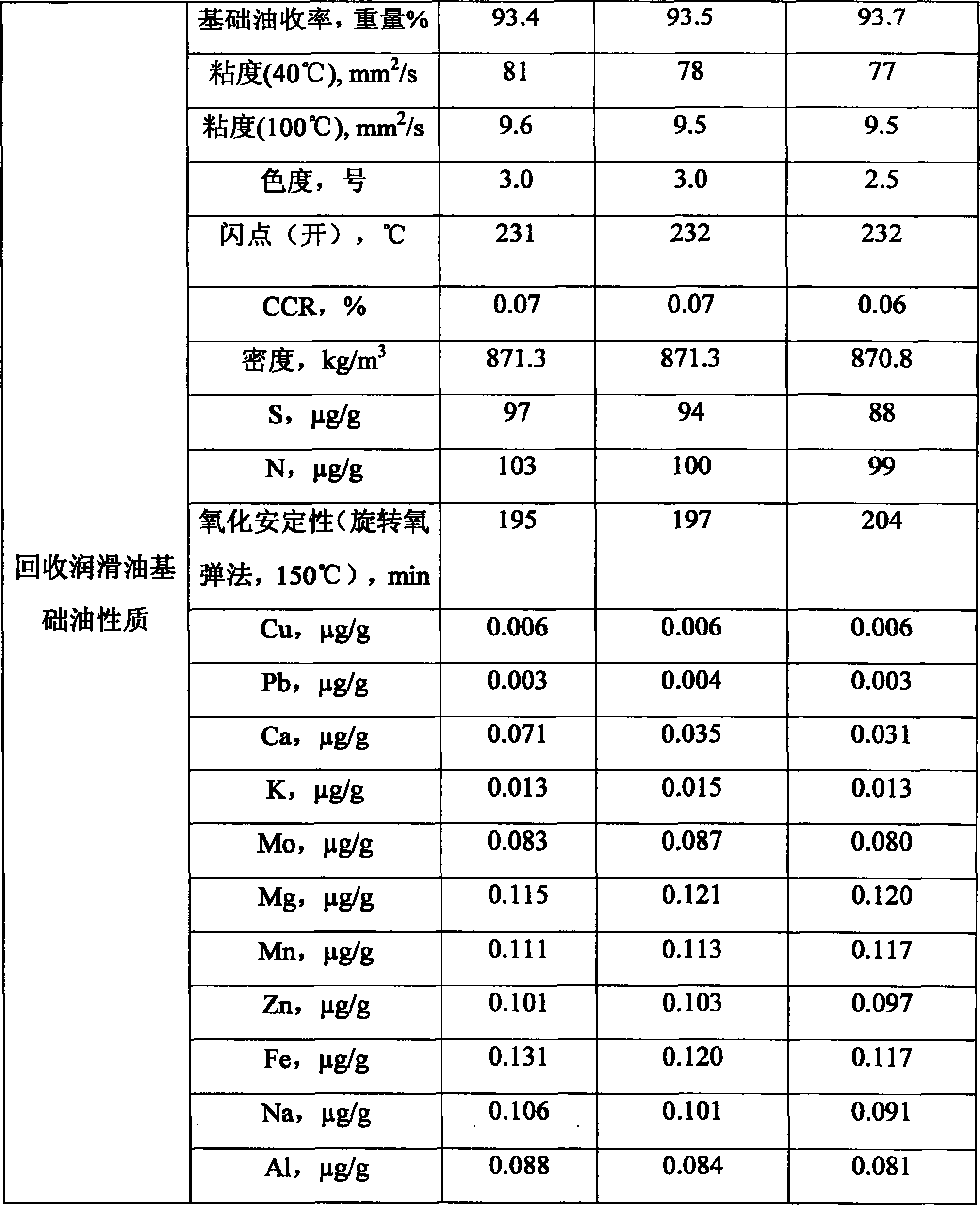

[0037] As shown in the figure, the oil product obtained after filtration, electric dehydration and desalination is mixed with H from pipeline 9 2 After mixing, enter the fluidized bed reactor 10 equipped with a demetallization catalyst for hydrodemetallization reaction, the reaction temperature is 320-350°C, the reaction pressure is 8-12MPa, and the volume space velocity is 0.5-1.0h -1 Then enter the fluidized bed reactor 11 equipped with hydrofinishing agent, carry out hydrofinishing reaction, reaction temperature 270~320 ℃, reaction pressure 6~8MPa, volumetric space velocity 1.0~1.5h -1 Then enter distillation tower 13 by pipeline 12 and carry out distillation, and hydrogen returns to 9 and enters reactor by pipeline 14, can recycle; Qualified lubricating oil base oil is distilled out by extraction outlet 15. The hydrodemetallization catalyst used in the ebullating bed reactor 10 contains MoO 3 (weight) 8%, containing NiO (weight) 2%, the catalyst is a microsphere with a di...

Embodiment 6~7

[0044] The waste gear oil whose basic properties are shown in Table 1 is processed on the combined process of the present invention.

[0045] The waste gear oil enters the filter 3 from the storage tank 1 through the pump 2 for filtration, the filtration temperature is 120°C, and an 800-mesh filter screen is selected; after filtration, polyoxyethylene alkylamine and polyoxyethylene fatty acid ester are added through the pipeline 4 The compounded demulsifier, added in an amount of 20 μg / g, is mixed evenly and enters two series-connected electric dehydration and demetallization tanks 5 and 6. The electric field strength in the tank is 1000V / cm, and the metal-containing sewage after dehydration is released from 7 and 8; Waste oil after electro-dehydration and demetallization and H from pipeline 9 2 After mixing, it enters the ebullated bed reactor 10 equipped with a demetallization catalyst to carry out hydrodemetallization reaction; then enters the ebullated bed reactor 11 equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com