Method for extracting mersosin by ultrasonic field assisted with mixed solvent

A technology of mixed solvent and extraction method, which is applied in the field of comprehensive extraction of azadirachtin, can solve the problems of slow extraction speed, low operating temperature, complex equipment, etc., and achieve the goal of increasing extraction rate, increasing production capacity, and increasing concentration gradient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

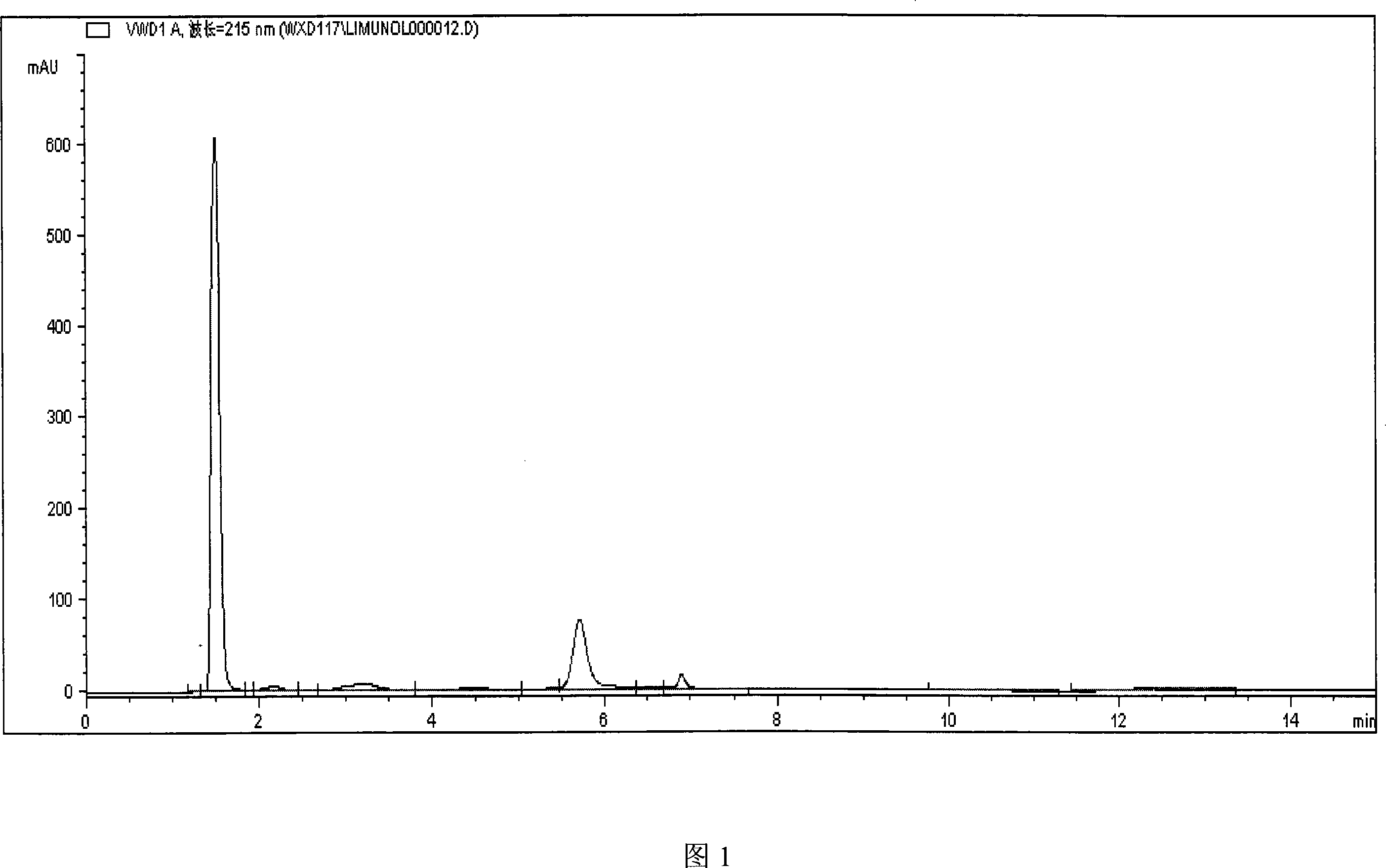

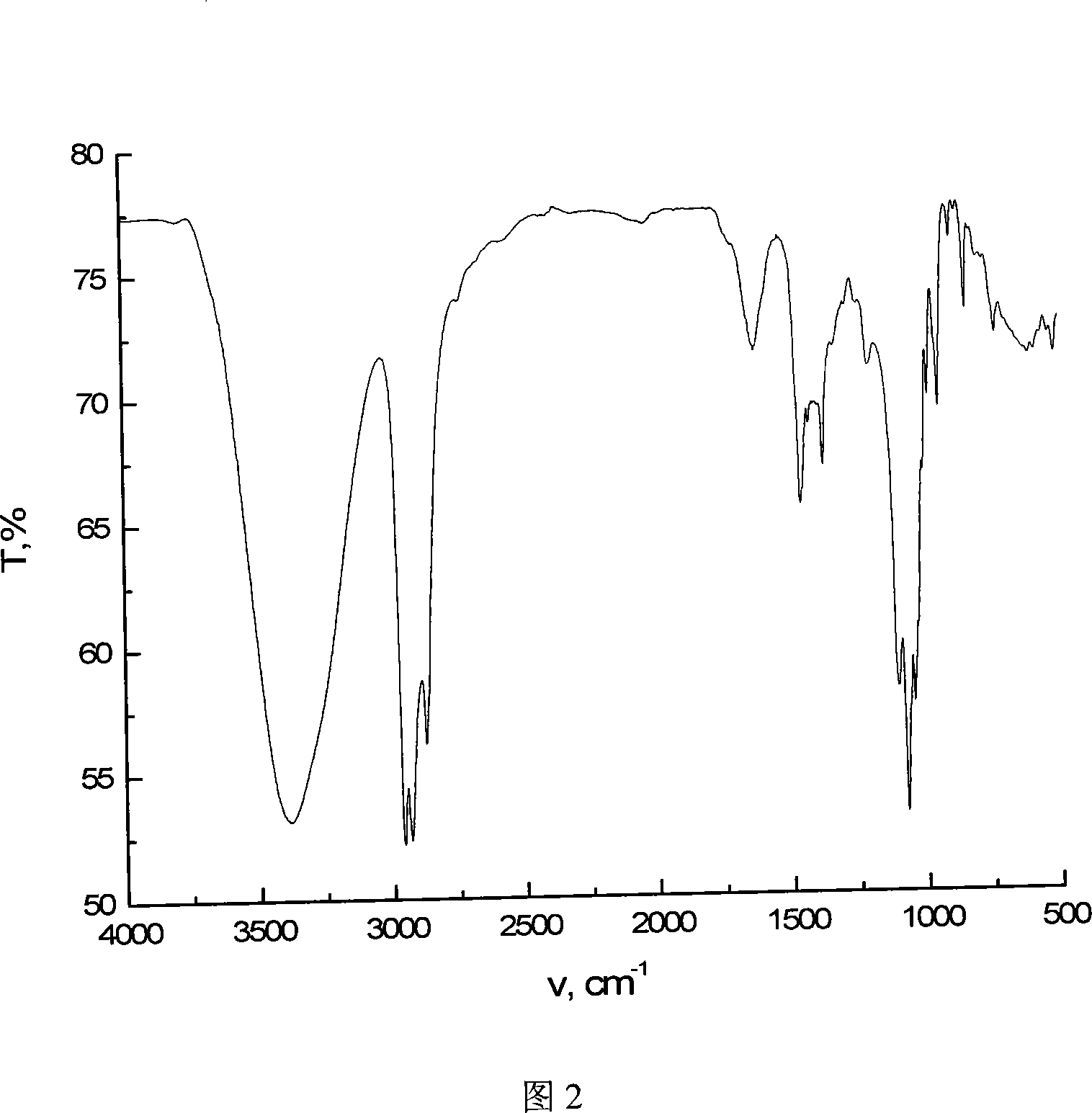

Image

Examples

Embodiment 1

[0022] Grind the dried neem bark to 60 mesh, put 10 grams in a 250mL flask, add 100mL of mixed solvent in a ratio of 1:10 and mix evenly, wherein the mixed solvent is prepared by mixing distilled water and ethanol analytical pure reagent , the volume concentration of ethanol in the mixed solvent is 70%, therefore, the polar parameter of the mixed solvent is 6.07, namely: ethanol 4.3×0.7+water 10.2×0.3, at ultrasonic frequency 40kHz, ultrasonic body power density 10W / L, leaching Extract at a temperature of 70°C for 40 minutes; after filtration, put the filter residue into a 250mL flask, add 100mL of the above mixed solvent again, and extract for 40 minutes at an ultrasonic frequency of 40kHz, an ultrasonic volume power density of 10W / L, and 70°C. After filtering, combine the filtrates, distill under reduced pressure, then add 50 mL of n-butanol to extract for 24 hours to obtain the extract, repeat 3 times, combine the extracts, evaporate and dry under reduced pressure to obtain ...

Embodiment 2

[0024] Grind the dried neem bark to 40 mesh, put 10 grams in a 250mL flask, add 150mL of mixed solvent in a ratio of 1:15 and mix evenly, wherein the mixed solvent is prepared by mixing distilled water and methanol analytical pure reagent , the volume concentration of methanol in the mixed solvent is 70%, therefore, the polar parameter of the mixed solvent is 7.68, namely: methanol 6.6×0.7+water 10.2×0.3, at ultrasonic frequency 45kHz, ultrasonic body power density 5W / L, leaching Extract at a temperature of 80°C for 30 minutes; after filtration, put the filter residue into a 250mL flask, add 150mL of the above mixed solvent, and extract again at an ultrasonic frequency of 45kHz, an ultrasonic volume power density of 5W / L, and 80°C for 30 minutes. After filtration, the filtrates were combined, distilled under reduced pressure, and then 50 mL of ethyl acetate was added to extract for 24 hours to obtain an extract. The extraction was repeated 3 times, and the extracts were combine...

Embodiment 3

[0026] Grind the dried neem seeds to 20 mesh, get 10 grams and place them in a 250mL flask, add 50mL of mixed solvent according to the ratio of 1:5 and mix evenly. The mixed solvent is analyzed by acetone and dichloromethane with a volume ratio of 1:1 Pure reagents are mixed and prepared. Therefore, the polarity parameter of the mixed solvent is 4.4, namely: acetone 5.4×0.5+dichloromethane 3.4×0.5, at an ultrasonic frequency of 100kHz, an ultrasonic volume power density of 20W / L, and an extraction temperature of 70°C , leaching for 40 minutes. After filtration, put the filter residue into a 250mL flask, add 50mL of the above-mentioned mixed solvent, and extract again at an ultrasonic frequency of 100kHz, an ultrasonic bulk power density of 20W / L, and 70°C for 40 minutes. After filtration, the filtrates were combined, distilled under reduced pressure, and then 50 mL of ethyl acetate was added to extract for 24 hours to obtain an extract, which was repeated 3 times. The extracts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com