Method for producing compound fertilizer by using humates simultaneously desulfurizing and denitrating

A desulfurization, denitrification, and humate technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of difficult industrial application, high desorption temperature, and difficult regeneration, and achieves good energy-saving effect. The effect of less pollution and easy cleaning and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

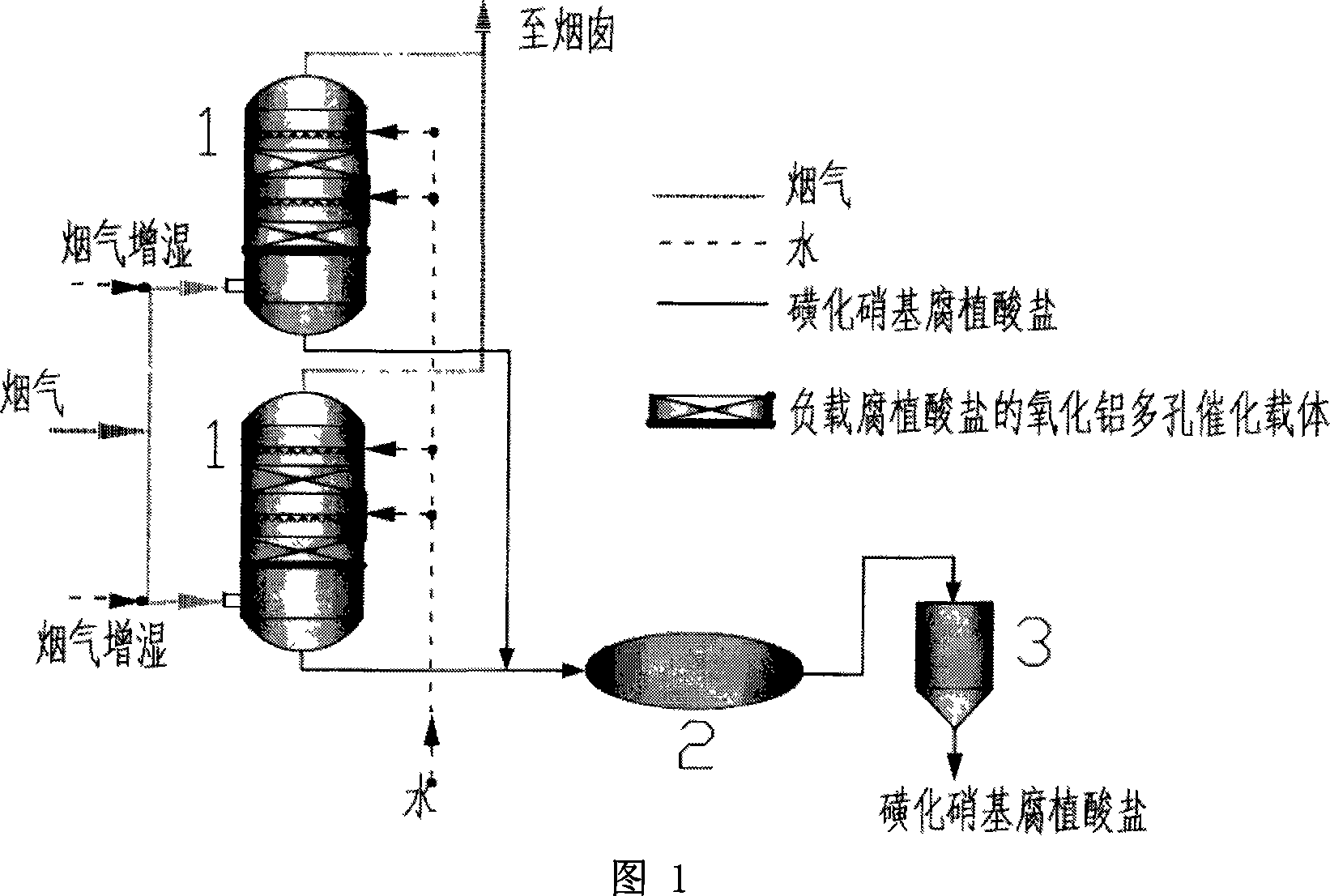

Embodiment 1

[0050] Use aluminum oxide fibers, the diameter of which is about 0.01 μm, extruded into a honeycomb shape, and then sintered into a porous carrier at 500 ° C. The porosity of the sintered porous carrier is 35%, and the specific gravity is 800kg / m 3 , the sintered porous catalyst support was coated with Cu(NO 3 ) 2 Sodium humic acid solution (mass percentage content is 20%), then dried at 60°C for 24 hours, baked at 400°C for 8 hours, then impregnated the porous catalytic carrier with sodium humate solution (mass percentage content is 1%), and loaded with smoke In the gas desulfurization and denitrification tower 1, an adsorption / absorption reaction layer is formed, and water mist is sprayed into the flue gas inlet section of the desulfurization and denitration tower 1 to humidify the flue gas, and the waste heat of the flue gas is used to vaporize the water mist, and the temperature of the reaction layer is controlled at At 80°C, under the action of hot and humid steam, the p...

Embodiment 2

[0052] Use aluminum oxide fibers with a diameter of 5 μm, extrude into a cuboid shape, and sinter at 900°C to form a porous carrier. The sintered porous carrier has a porosity of 60% and a specific gravity of 550kg / m 3 , the sintered porous support in Ni(COOCH 3 ) 2 (mass percentage content is 8%) impregnated in the solution, then dried at 110 DEG C for 12 hours, roasted at 600 DEG C for 6 hours, then impregnated the porous catalytic carrier with potassium humate solution (mass percentage content was 20%), loaded into smoke In the gas desulfurization and denitrification tower 1, an adsorption / absorption reaction layer is formed, and water mist is sprayed into the flue gas inlet section of the desulfurization and denitration tower 1 to humidify the flue gas, and the waste heat of the flue gas is used to vaporize the water mist, and the temperature of the reaction layer is controlled at At 180°C, under the action of hot and humid steam, the porous catalytic carrier loaded with ...

Embodiment 3

[0054] Use aluminum oxide fibers, the diameter of which is about 30 μm, extruded into a honeycomb shape, and then sintered into a porous carrier at 1500 ° C. The porosity of the sintered porous carrier is 85%, and the specific gravity is 300kg / m 3 , impregnate the porous catalytic carrier after sintering in cobalt nitrate solution (mass percentage content is 0.1%), then dry at 200 DEG C for 8 hours, roast at 900 DEG C for 4 hours, then impregnate the porous catalytic carrier with potassium humate solution (mass After the percentage content is 50%), it is loaded into the flue gas desulfurization and denitrification tower 1 to form an adsorption / absorption reaction layer. Humidify the flue gas entering the desulfurization and denitrification tower 1 to obtain a hot and humid steam environment, use the waste heat of the flue gas to vaporize the water mist, control the temperature of the desulfurization and denitrification reaction layer at 300 ° C, and the reaction layer is loaded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com