Metal modified polymethyl silicane, preparation method and application thereof

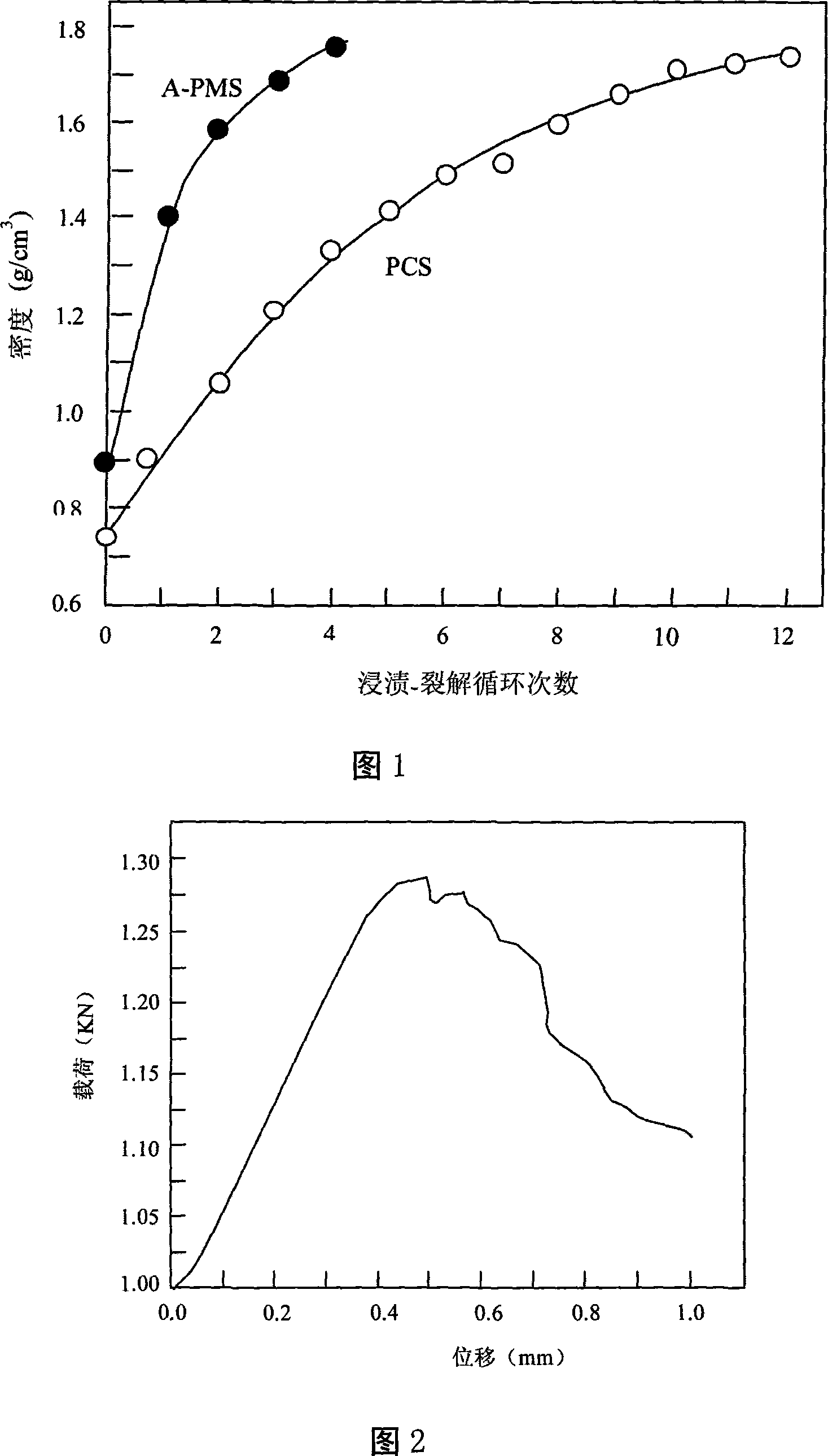

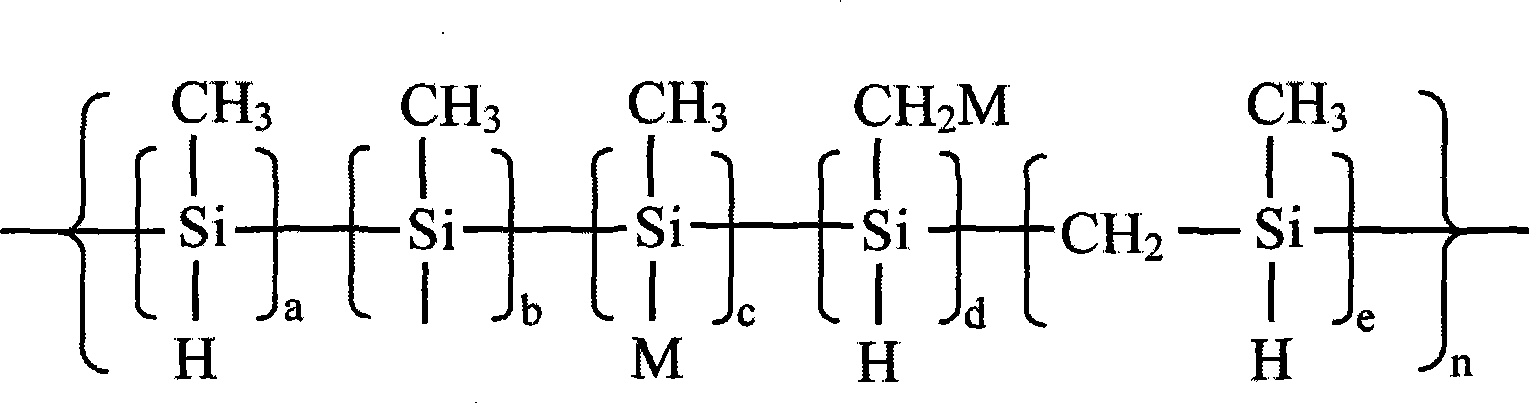

A technology of polymethylsilane and metal modification, which is applied in the field of preparation of precursor-metal-modified polymethylsilane, can solve the problems of long preparation time, low ceramic yield, high temperature oxidation resistance and other performance degradation, and achieves The effect of reducing manufacturing costs, reducing use costs, and reducing the number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In a 1000ml three-necked flask equipped with a stirrer, a condenser, and a nitrogen inlet pipe, add 100g of polymethylsilane and 0.5g of trifluoromethylmethylsiloxane, stir well under the protection of nitrogen, and then add the crushed and refined SbCl 3 5g, control the flow of nitrogen gas at 100-1000ml / min, stir rapidly for 1-2 hours, then reduce the rotation speed to about 300-400 rpm, and react at room temperature for 10-12 hours. The HCl produced by the reaction is introduced into the water through the air duct until The gas generated by the airway will no longer turn the pH test paper red, and the reaction can be stopped; the small molecular substances are removed by vacuum filtration, and the obtained liquid substance is antimony-modified polymethylsilane, which is liquid at room temperature and has a molecular weight of 500. , the viscosity is 0.26Pa·s.

[0027] The precursor is directly cracked at a high temperature of 1200°C under the protection of high-puri...

Embodiment 2

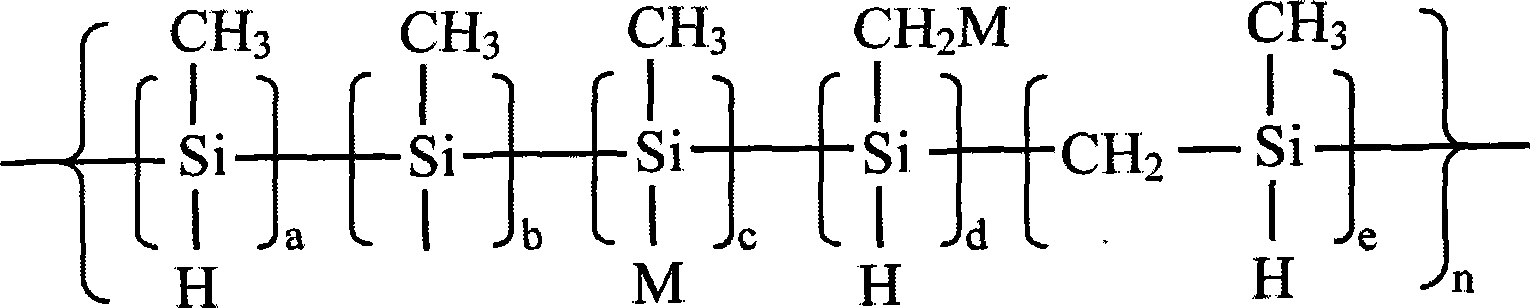

[0033] In a 1000ml three-neck flask equipped with a stirrer, condenser tube, and nitrogen inlet tube, add 100g of polymethylsilane and 0.8g of diphenylsiloxane, and stir well under the protection of nitrogen, then add CrCl 3 10g, control the flow of nitrogen gas at 300-2000ml / min, after stirring for 3 hours, reduce the speed to about 200-400 rpm, and fully react for about 12-15 hours at 100-150°C. In water, until the gas generated by the airway tube no longer makes the pH test paper turn red, the reaction can be stopped, and the small molecular substances are removed by vacuum filtration, and the obtained liquid substance is chromium-modified polymethylsilane, which is liquid at room temperature. The molecular weight is 800, and the viscosity is 0.36Pa.s. The precursor was directly cracked at a high temperature of 1200°C under the protection of high-purity nitrogen, and its Si / C was 1.09. This material is used as a precursor impregnating agent, and the silicon carbide fiber b...

Embodiment 3

[0039] In a 1000ml three-necked flask equipped with a stirrer, a condenser, and a nitrogen inlet tube, add 100g of polymethylsilane and 0.5g of trifluoroalkylalkylsiloxane, and stir well under the protection of nitrogen, and then add FeCl 34.8g, control the larger nitrogen flow rate of 100-1000ml / min, stir rapidly for 1-2 hours, then reduce the speed to about 300-400 rpm, fully react for about 10-12 hours, the HCl produced by the reaction passes through the airway, and introduces In water, until the gas generated by the airway tube no longer makes the pH test paper turn red, the reaction can be stopped, and the small molecular substances are removed by vacuum filtration, and the obtained liquid substance is iron-modified polymethylsilane, which is liquid at room temperature. The molecular weight is 1000, the viscosity is 0.32Pa.s, the precursor is directly cracked at a high temperature of 1200°C under the protection of high-purity nitrogen, and its Si / C is 1.18. This material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com