A vanadium adulterated TiOx nano lanthanon magnetic semiconductor and its making method

A dilute magnetic semiconductor and titanium oxide technology, which is applied in the manufacture of titanium dioxide, titanium oxide/hydroxide, inductors/transformers/magnets, etc., can solve the problem of vanadium-doped titanium oxide nano-dilute magnetic semiconductor without powder, etc., to achieve Ease of popularization, cheap equipment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

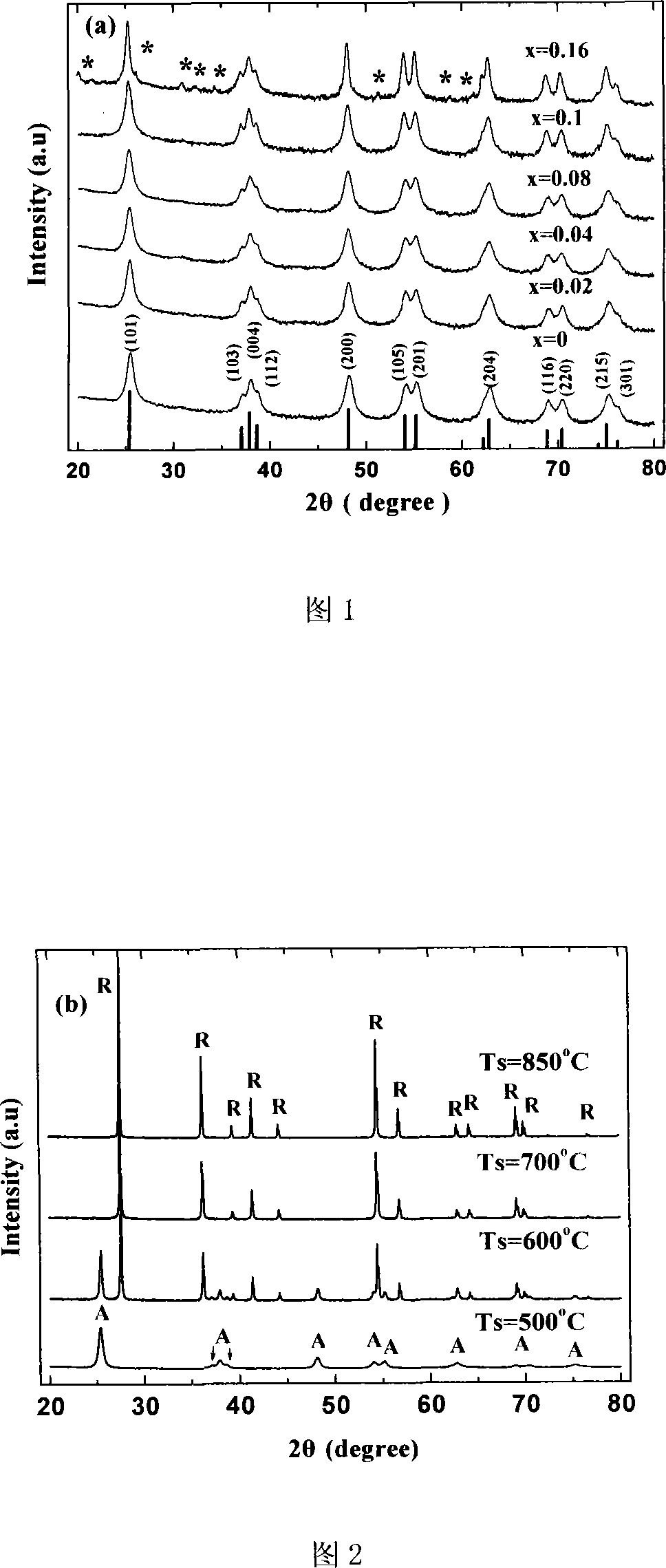

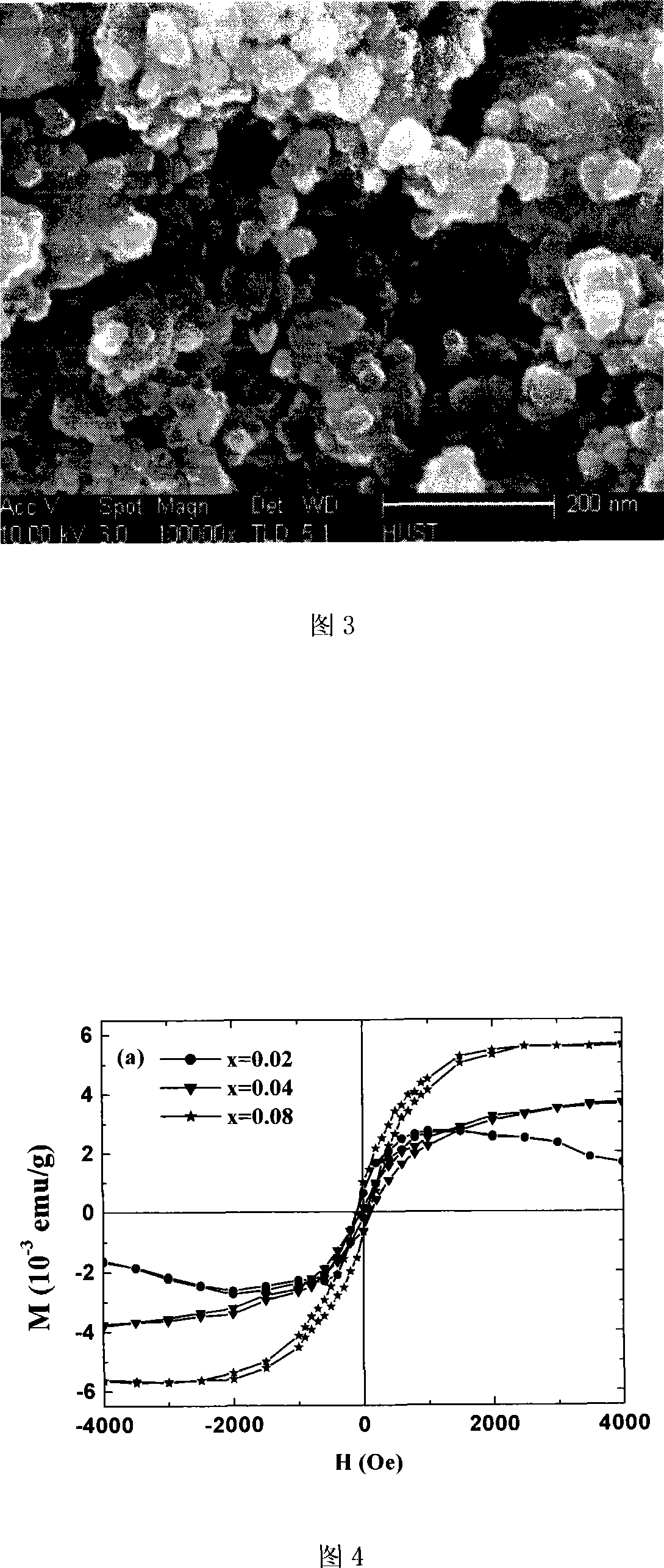

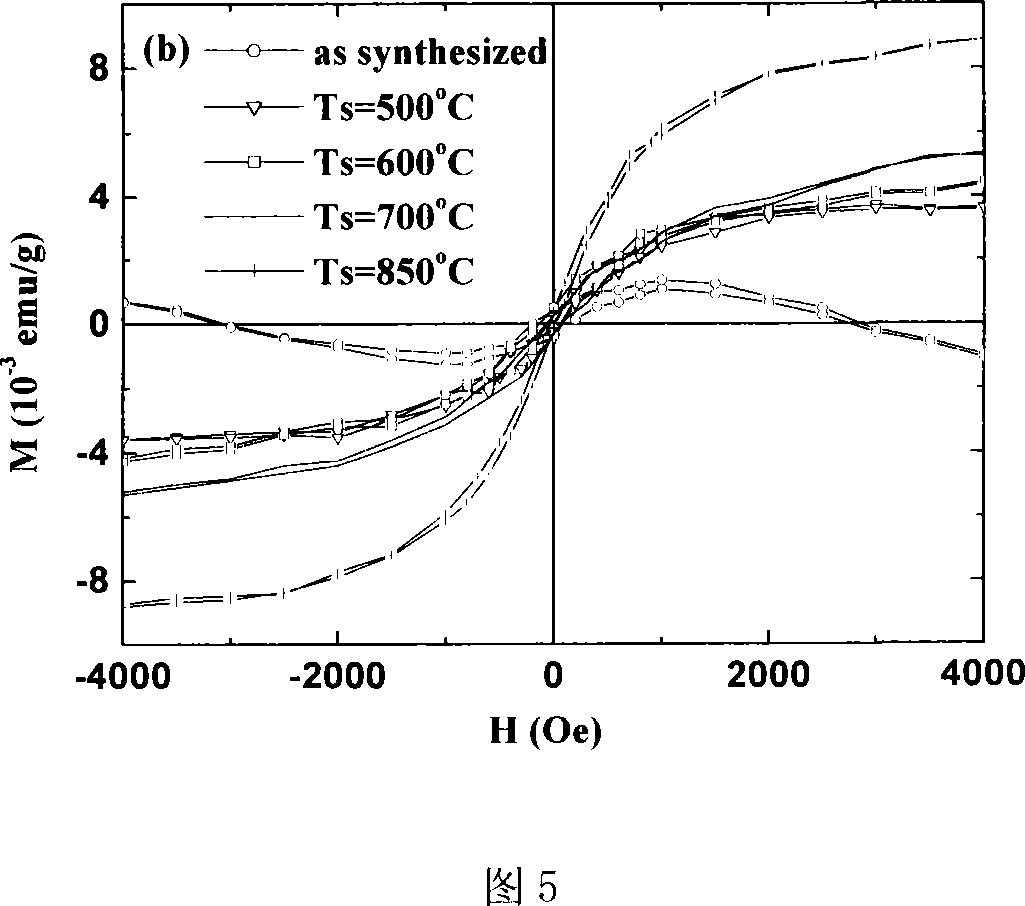

[0020] Utilize the method of the present invention, prepare the Ti of 500 ℃ annealing treatment 1-x V x o 2 (x=0.08) Nanopowder. First, weigh 0.01 mol of ammonium metavanadate and put it into a 100mL beaker, add 30mL of glacial acetic acid, dissolve it under ultrasonic dispersion, wash the beaker continuously with absolute ethanol, transfer the solution into a 100mL volumetric flask, add absolute ethanol to adjust When the concentration reaches 0.05mol / L, prepare a precursor solution of vanadium ions; in addition, dissolve tetrabutyl titanate in absolute ethanol, transfer the solution into a 100mL volumetric flask, and prepare a precursor solution of 0.5M titanium ions. In the second step, use a 10mL graduated pipette to take 40mL of the solution containing titanium ions and place it in a 100mL beaker, then use a 2mL graduated pipette to take 3.5mL of the solution containing vanadium ions, and quickly drop it into the above solution while stirring continuously. The molar ra...

Embodiment 2

[0022] Utilize the method of the present invention, prepare the Ti of 500 ℃ annealing treatment 1-x V x o 2 (x=0.04) Nanopowder. First, weigh 0.01 mol of ammonium metavanadate and put it into a 100mL beaker, add 30mL of glacial acetic acid, dissolve it under ultrasonic dispersion, wash the beaker continuously with absolute ethanol, transfer the solution into a 100mL volumetric flask, add absolute ethanol to adjust When the concentration reaches 0.05mol / L, prepare a precursor solution of vanadium ions; in addition, dissolve tetrabutyl titanate in absolute ethanol, transfer the solution into a 100mL volumetric flask, and prepare a precursor solution of 0.5M titanium ions. In the second step, use a 10mL graduated pipette to take 40mL of the precursor solution containing titanium ions and place it in a 100mL beaker, then use a 2mL graduated pipette to take 1.7mL of the precursor solution of vanadium ions, and quickly drop it into the above solution while stirring continuously ,...

Embodiment 3

[0024] Utilize the method of the present invention, prepare the Ti of 600 ℃ annealing treatment 1-x V x o 2 (x=0.04) of nanopowder. First, weigh 0.01 mol of ammonium metavanadate and put it into a 100mL beaker, add 30mL of glacial acetic acid, dissolve it under ultrasonic dispersion, wash the beaker continuously with absolute ethanol, transfer the solution into a 100mL volumetric flask, add absolute ethanol to adjust When the concentration reaches 0.75mol / L, prepare a precursor solution of vanadium ions; in addition, dissolve tetrabutyl titanate in absolute ethanol, transfer the solution into a 100mL volumetric flask, and prepare a precursor solution of 0.5M titanium ions. In the second step, use a 10mL graduated pipette to take 40mL of the precursor solution of titanium ions and place it in a 100mL beaker, then use a 2mL graduated pipette to take 1.7mL of the precursor solution of vanadium ions, and quickly drop it into the above solution while stirring continuously. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com