Method for producing gellan gum finished product from gellan gum fermentation liquor

A technology of gellan gum and fermentation broth, applied in fermentation and other directions, can solve problems such as turbidity, inability to filter and clarify, and microfiltration membrane is easily damaged, and achieves the effect of reducing the amount of alcohol, low production cost, and good clarifying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

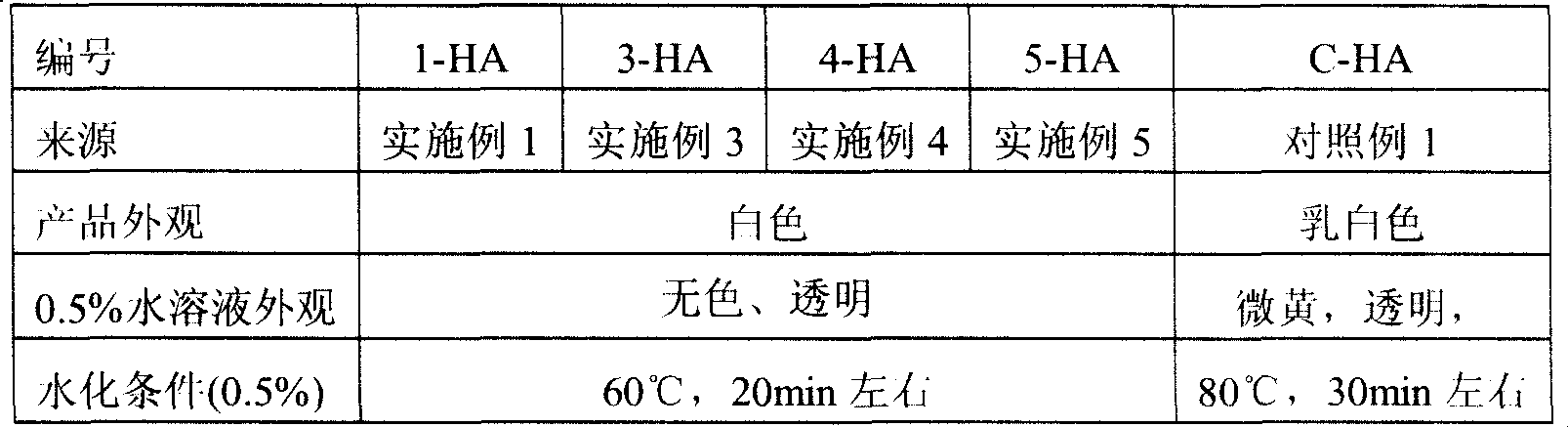

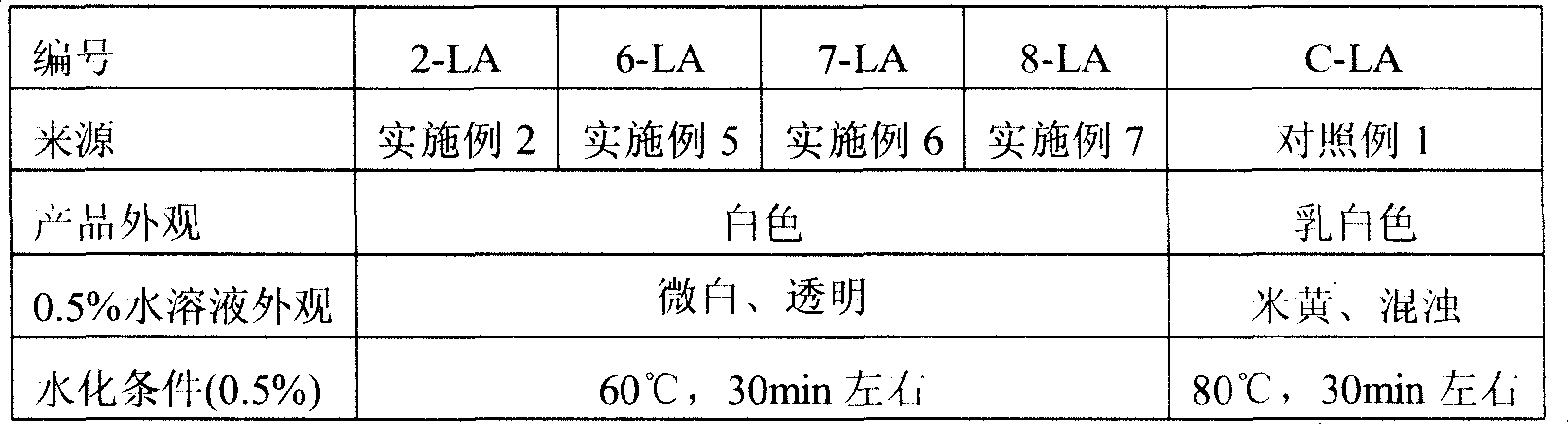

Examples

Embodiment 1

[0077] A. Concentration process

[0078] 1. Add about 250L of 20% magnesium sulfate solution to the flocculation tank with 10m3 fermentation broth at normal temperature, and add 500L of 40% sodium hydroxide solution while stirring to obtain the flocculation fermentation broth.

[0079] 2. Use a pump to send the flocculation fermentation liquid to a plate and frame filter press for filtration and dehydration, and top wash with clean water, and unload to obtain 2000kg of gellan gum flocs.

[0080] 3. Feed the gellan gum floc into the desalination washing tank, add about 1m3 of 90% (v / v) isopropanol solution, stir and disperse, the concentration of isopropanol in the dispersion is about 50% (v / v), Use hydrochloric acid to adjust the pH to about 5.0, and after about 60 minutes, use a three-legged centrifuge to filter and remove the liquid to obtain about 1200 kg of crude gellan gum.

[0081] B. Redissolution process

[0082] 4. Add about 5m3 of water to the sol tank, heat up to ...

Embodiment 2

[0090] A. Concentration process

[0091] 1. Add about 15 m3 of 98% (v / v) isopropanol into a flocculation tank equipped with 10 m3 fermented liquid, stir evenly, and obtain the flocculated fermented liquid.

[0092] 2. Use a pump to send the flocculation fermentation liquid to the plate and frame filter press to filter and deliquify.

[0093] 3. Unload after top washing with a small amount of isopropanol to obtain 700kg of wet crude gellan gum.

[0094] B. Redissolution process

[0095] 4. Add about 3.5m3 of water to the sol tank, heat up to 80°C, add all the above-mentioned crude gellan gum, stir to dissolve, and obtain gellan gum turbid liquid.

[0096] 4a. Alkali treatment: Add lye to the gellan gum turbid solution while it is hot to make the pH of the gel solution 9.5-10.5, keep it for about 10 minutes, and then use acid solution to lower the pH to 6.0-8.0.

[0097] C. Clarification process

[0098] 5. While hot, use a vacuum drum machine pre-coated with diatomaceous ea...

Embodiment 3

[0104] With reference to the method of Example 1, the difference lies in steps 1-3:

[0105] 1. Add about 10m3 of 95% (v / v) ethanol to the flocculation tank equipped with 10m3 fermented liquid, stir evenly to obtain the flocculated fermented liquid.

[0106] 2. Use a pump to send the flocculation fermentation liquid to a plate and frame filter press to filter and deliquify, and unload to obtain 1200kg of wet crude gellan gum.

[0107] 3. Feed the crude product of gellan gum into a washing tank, add about 500 L of 90% (v / v) ethanol solution, stir and disperse, then filter and remove the liquid with a three-legged centrifuge to obtain about 700 kg of crude product of gellan gum. The product is a high acyl gellan gum product, recorded as 3-HA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com