Method for producing large area polysilicon

A polysilicon, large-area technology, applied in polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve the problems of large-area uniformity and poor repeatability, high cost of laser equipment, small irradiation area, etc., to achieve crystallization Short conversion time, ensuring uniformity and repeatability, and good radiation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

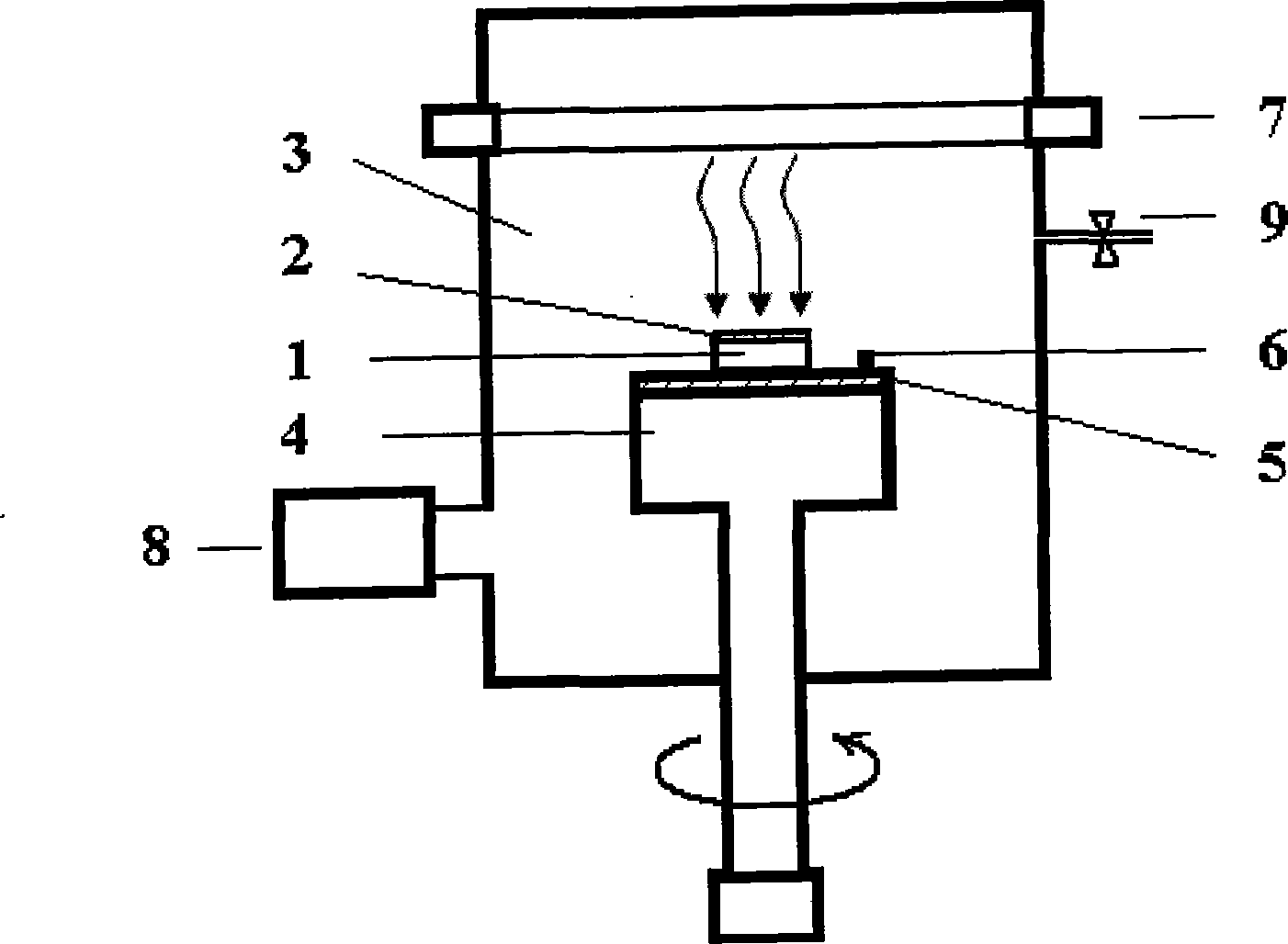

[0015] Embodiment 1: referring to accompanying drawing, at first on common glass substrate 1, use plasma-enhanced chemical vapor deposition (PECVD) to deposit a 4 inch diameter area, the amorphous silicon film 2 that thickness is 50nm; The glass substrate 1 of the crystalline silicon thin film 2 is shifted on the rotatable stage 4 in the vacuum chamber 3 (this method can obtain higher uniformity of the large-area film). A xenon excimer ultraviolet lamp 7 is installed directly above the stage in the vacuum chamber 3, providing up to 100mW / cm 2 The light intensity, the distance between the stage 1 and the excimer ultraviolet lamp 7 is 8cm, and there is a plane temperature control heating element 5 and a thermocouple temperature measuring device 6 on the stage. Turn on the vacuum pump system 8 connected to the vacuum chamber 3 to evacuate, repeatedly flush the inner wall of the vacuum chamber with an inert gas such as argon or nitrogen or neon through the inlet valve 9, maintain ...

Embodiment 2

[0016] Embodiment 2: As in Embodiment 1, wherein the light source for irradiation is a krypton excimer lamp.

Embodiment 3

[0017] Embodiment 3: as embodiment 1, wherein the irradiation light source is an argon excimer lamp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com