Method for manufacturing high-strength aluminium-magnesium-slicon alloy wire

A manufacturing method, Al-Mg-Si technology, applied in temperature control, metal rolling, etc., can solve problems such as the unoptimized strength residual rate and unstable manufacturing process, and achieve good crystallization state, excellent performance, and improved electrical conductivity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

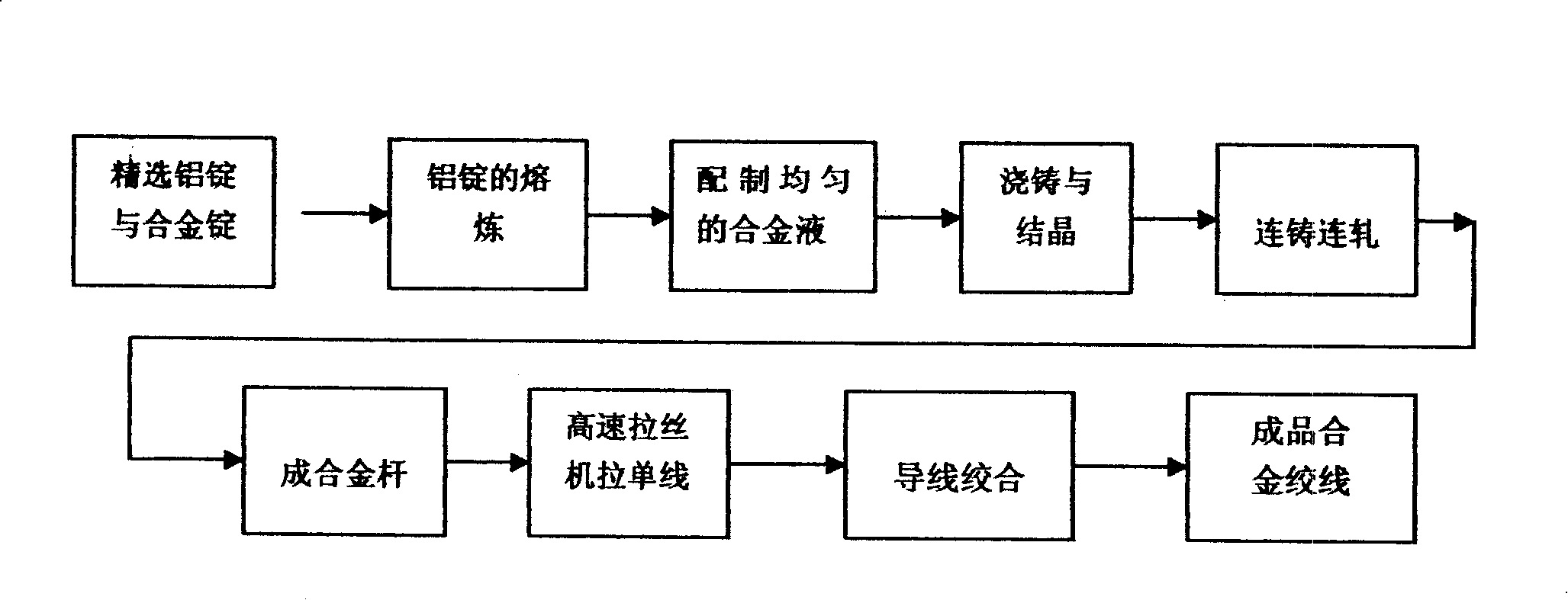

[0019] Such as figure 1 Shown is the manufacturing process flow chart of the present invention, and all equipments used in the present invention are outsourced.

[0020] A method of manufacturing high-strength aluminum-magnesium-silicon alloy wire is: select an aluminum ingot with an impurity content of (titanium Ti+vanadium V+chromium Cr+manganese Mn) ≤ 0.015%, and other impurities ≤ 0.03%; put it into a shaft furnace for melting; add Make it range up to 0.62% magnesium, 0.90% silicon, 0.4% iron and 98.08% aluminum as additive elements for alloying treatment; aluminum liquid is alloyed in a tiltable holding furnace, and the temperature of the furnace is controlled At 900°C, the temperature of the molten aluminum is controlled at 740°C and treated evenly by stirring, refining and refining grains with solid or gas-solid mixed refining agent sodium salt, hexahalogenethane and sodium salt nitrogen, and solid covering agent cryolite powder Cover the surface of the aluminum liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com