Electric bonding for battery or capacitor and composition containing the same used for electrode

A conductive adhesive and capacitor technology, which is applied in the direction of battery electrodes, conductive adhesives, adhesives, etc., can solve the problems of reducing the specific capacity of batteries or capacitors, reducing the relative mass ratio of active materials, etc., so as to reduce contact resistance and improve electric current Chemical properties, the effect of increasing the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

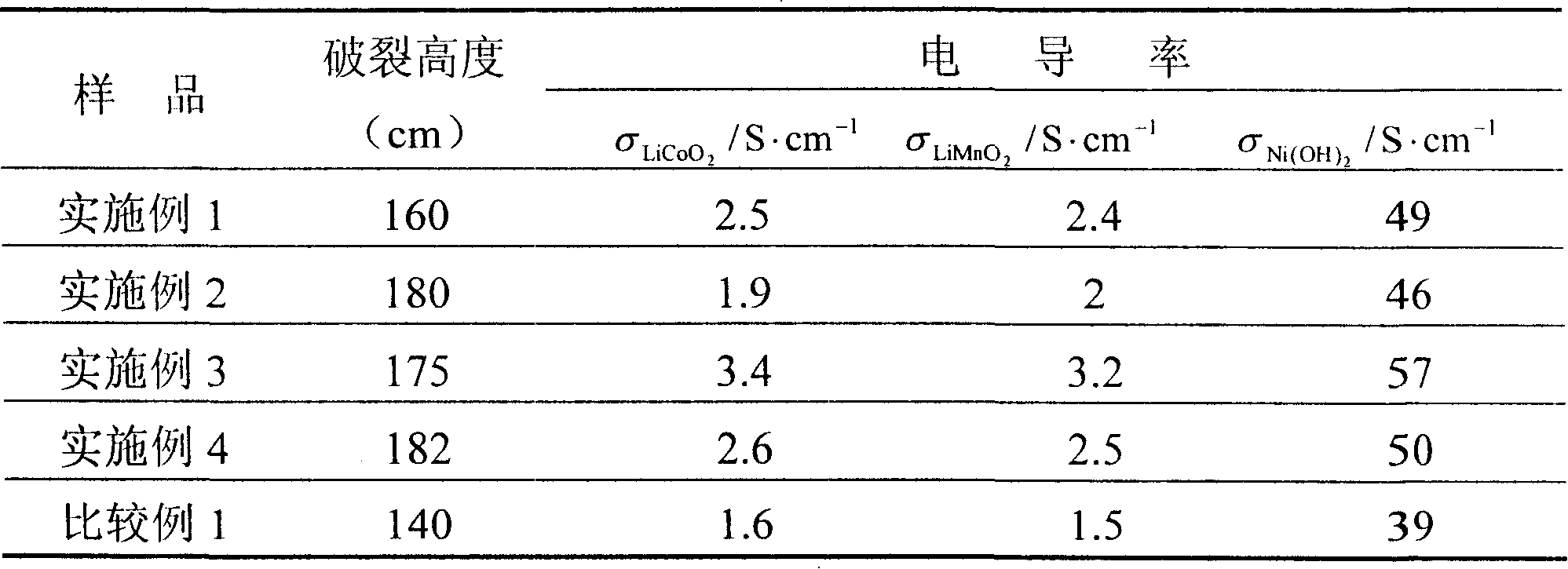

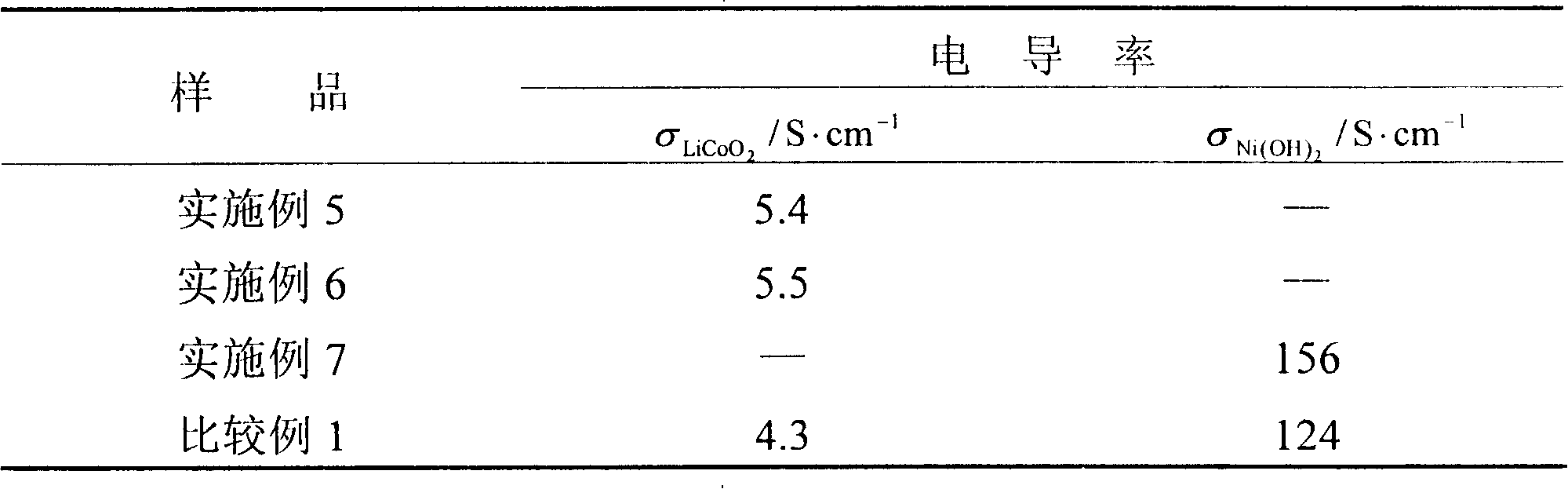

Examples

Embodiment 1

[0010] Put aniline monomer in 1mol / l hydrochloric acid aqueous solution, use ammonium persulfate as an initiator, react at 0-5°C by chemical oxidation method, filter and dry to obtain polyaniline doped with hydrochloric acid, and use ammonia water for reverse doping complex, forming intrinsic polyaniline. Use dodecylbenzenesulfonic acid (DBSA) to carry out functional protonation treatment, and after drying, dark green conductive polyaniline powder is obtained; polyethylene oxide (PEO) with a mass ratio of 1:1 to aniline is put into a container filled with 30ml N -In a three-neck flask of methylpyrrolidone (NMP), stir until PEO is completely dissolved; then add conductive polyaniline dissolved in NMP into the three-necked flask according to the proportion, mix and stir for 3 hours, and obtain polyaniline with a polyaniline content of 50%. - Polyethylene oxide conductive adhesive.

Embodiment 2

[0012] Add 1ml of N-methylpyrrolidone solution to the substances shown in the following mass percentages, and mix to form a conductive adhesive.

[0013] Polyaniline electronically conductive polymer 35

[0014] Polyethylene oxide ion-conducting polymer 60

[0015] Conductive agent 1

[0016] Auxiliary 4

Embodiment 3

[0018] Add 1ml of N-methylpyrrolidone solution to the substances shown in the following mass percentages, and mix to form a conductive adhesive.

[0019] Polyaniline electronically conductive polymer 50

[0020] Polyethylene oxide ion-conducting polymer 40

[0021] Conductive agent 5

[0022] Auxiliary 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com