Chromium doped titanium dioxide ferromagnetic film room temperature preparation method

A ferromagnetic thin film, room temperature technology, applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc. The effect of increasing the moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

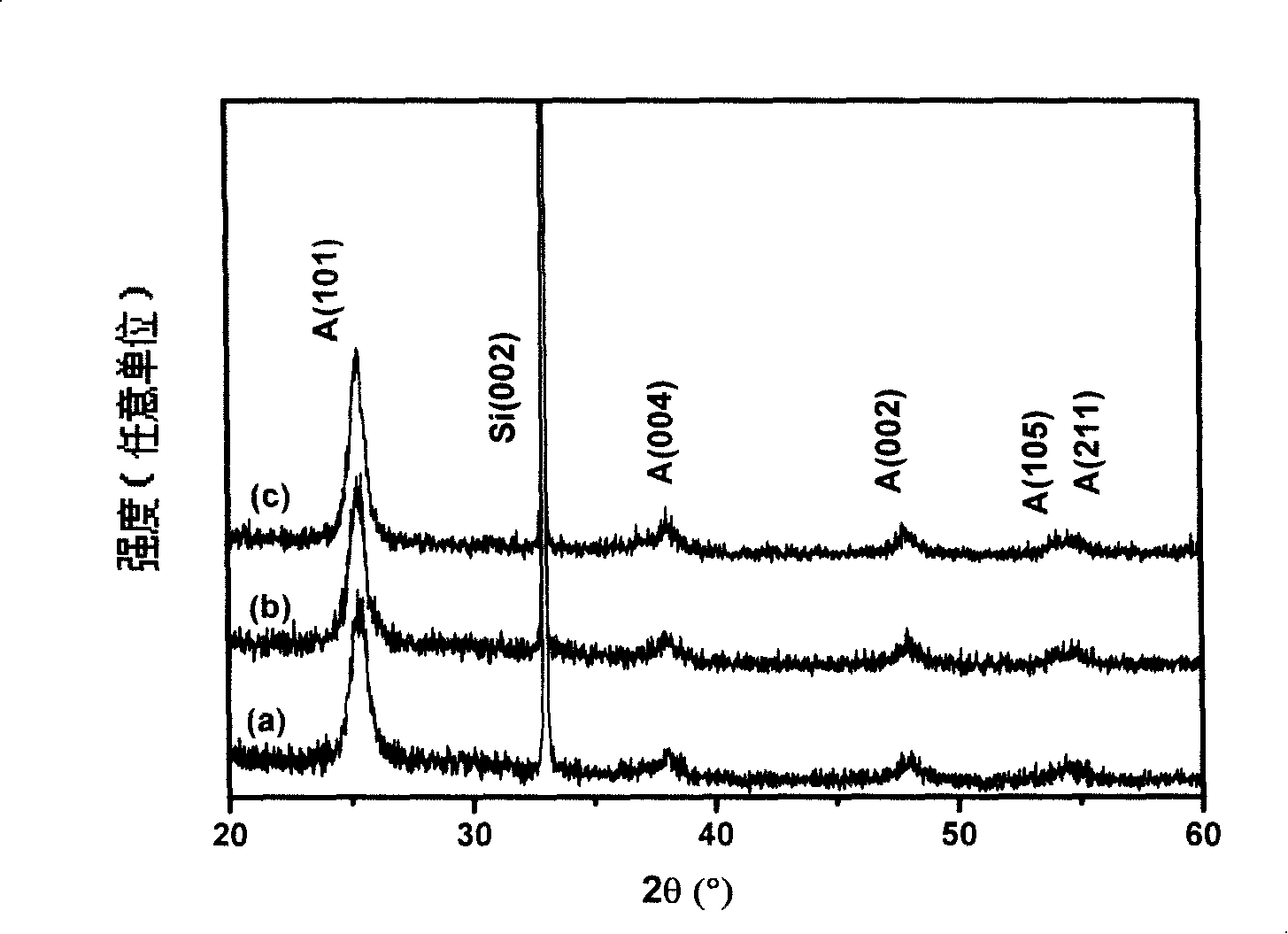

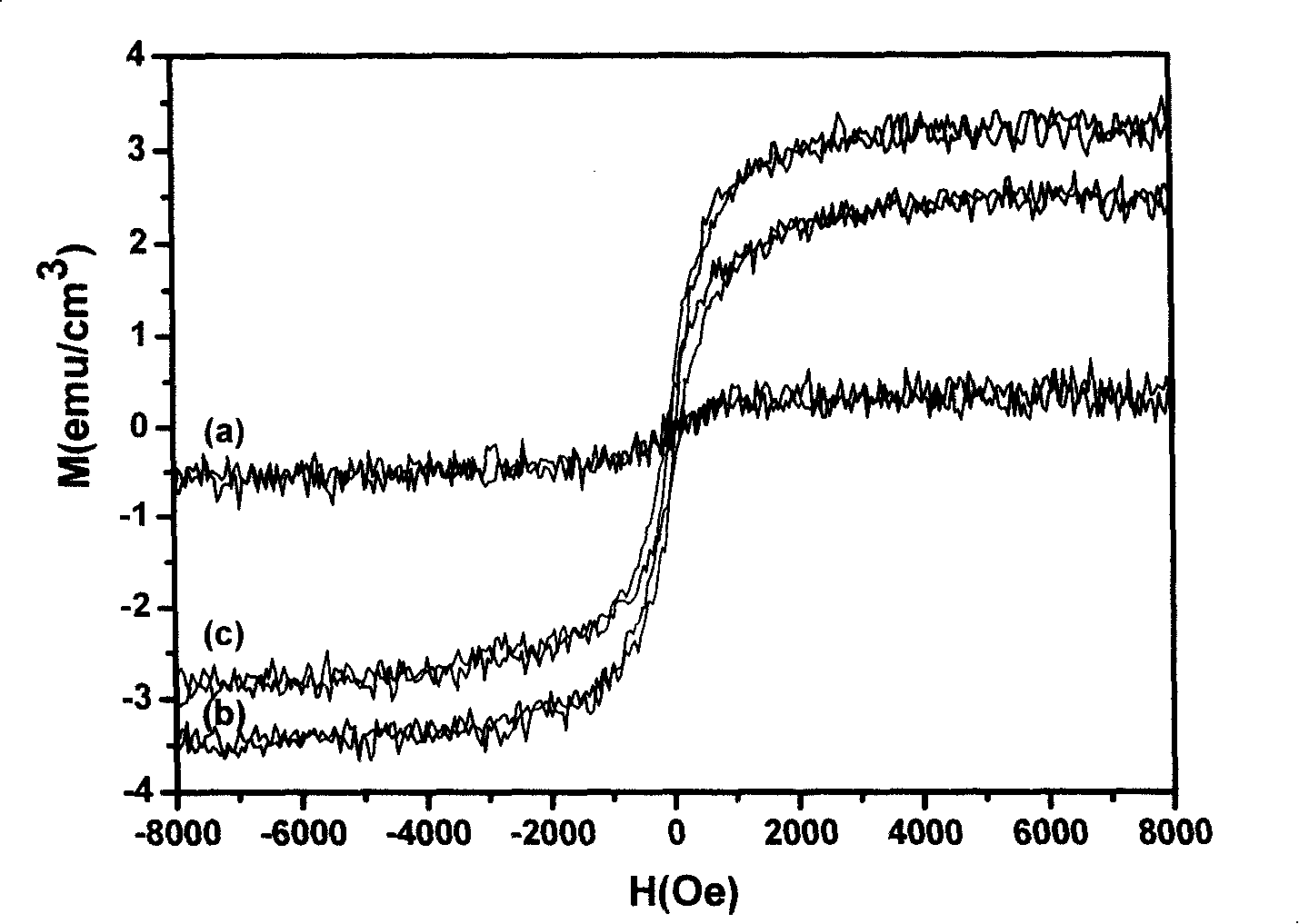

[0019] Embodiment 1 Sol-gel method prepares Cr x Ti 1-x o 2 (x=0.05) film

[0020] Preparation of Cr on Si(001) Single Crystal Substrate by Sol-Gel Method 0.05 Ti 0.95 o 2 film. Utilize tetra-n-butyl titanate and chromium chloride as precursors (Cr:Ti molar ratio is 5:95), dissolve them in absolute ethanol (concentration of solution is 0.1mol / L), add acetylacetone as complex Mixture, nitric acid as a catalyst, drop an appropriate amount of deionized water, use a magnetic stirrer to stir the solution at room temperature for 3 hours to fully mix the solution, and place it in the air for two days to obtain stable Cr-doped TiO2 Sol. Cr-doped TiO 2 The sol was evenly coated on the Si(001) single crystal substrate. The spin coating process of the sol was first carried out at 500rpm for 10 seconds, and then at 3000rpm for 40 seconds to obtain a uniform thickness of Cr 0.05 Ti 0.95 o 2 Sol-gel films. After the film is dried at 100°C for 10 minutes, the next film spin coatin...

Embodiment 2

[0022] Embodiment 2 sol-gel method prepares Cr x Ti 1-x o 2 (x=0.03) film

[0023] Preparation of Cr on Si(001) Single Crystal Substrate by Sol-Gel Method 0.03 Ti 0.97 o 2 film. Using tetra-n-butyl titanate and chromium acetate as precursors (Cr:Ti molar ratio is 3:97), they are co-dissolved in ethylene glycol (concentration of solution is 0.1mol / L), and glacial acetic acid is added as complex Mixture, nitric acid as a catalyst, drop an appropriate amount of deionized water, use a magnetic stirrer to stir the solution at room temperature for 3 hours to fully mix the solution, and heat and age at 60°C for 12 hours to obtain stable Cr-doped TiO 2 Sol. Cr-doped TiO 2 The sol was coated on the Si(001) substrate by first spin-coating at 500 rpm for 10 s, then at 3000 rpm for 40 s to obtain a uniform thickness of Cr 0.03 Ti 0.97 o 2 Sol-gel films. After the film is dried at 80°C for 15 minutes, the next film spin coating is performed, and then the spin coating is repeate...

Embodiment 3

[0025] Embodiment 3 sol-gel method prepares Cr x Ti 1-x o 2 (x=0.1) film

[0026] Preparation of Cr on Si(001) Single Crystal Substrate by Sol-Gel Method 0.1 Ti 0.9 o 2 film. Utilize tetra-n-butyl titanate and chromium chloride as precursors (Cr:Ti molar ratio is 10:90), dissolve them in ethylene glycol (concentration of solution is 0.1mol / L), add acetylacetone as complex Mixture, hydrochloric acid as a catalyst, drop an appropriate amount of deionized water, use a magnetic stirrer to stir the solution at room temperature for 3 hours to fully mix the solution, heat and age at 60°C for 12 hours, and obtain stable Cr-doped TiO 2 Sol. Cr-doped TiO 2 The sol was coated on the Si(001) substrate by first spin-coating at 500 rpm for 10 s, then at 3000 rpm for 40 s to obtain a uniform thickness of Cr 0.1 Ti 0.9 o 2 Sol-gel films. After the film is dried at 120°C for 10 minutes, the next film spin coating is performed, and then the spin coating is repeated to obtain a film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com