Method for preparing Yb3Al5O12 nano powder by urea precipitation method

A yb3al5o12, nano-powder technology, applied in the direction of alumina/aluminum hydroxide, etc., to achieve good steric hindrance and prevent particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

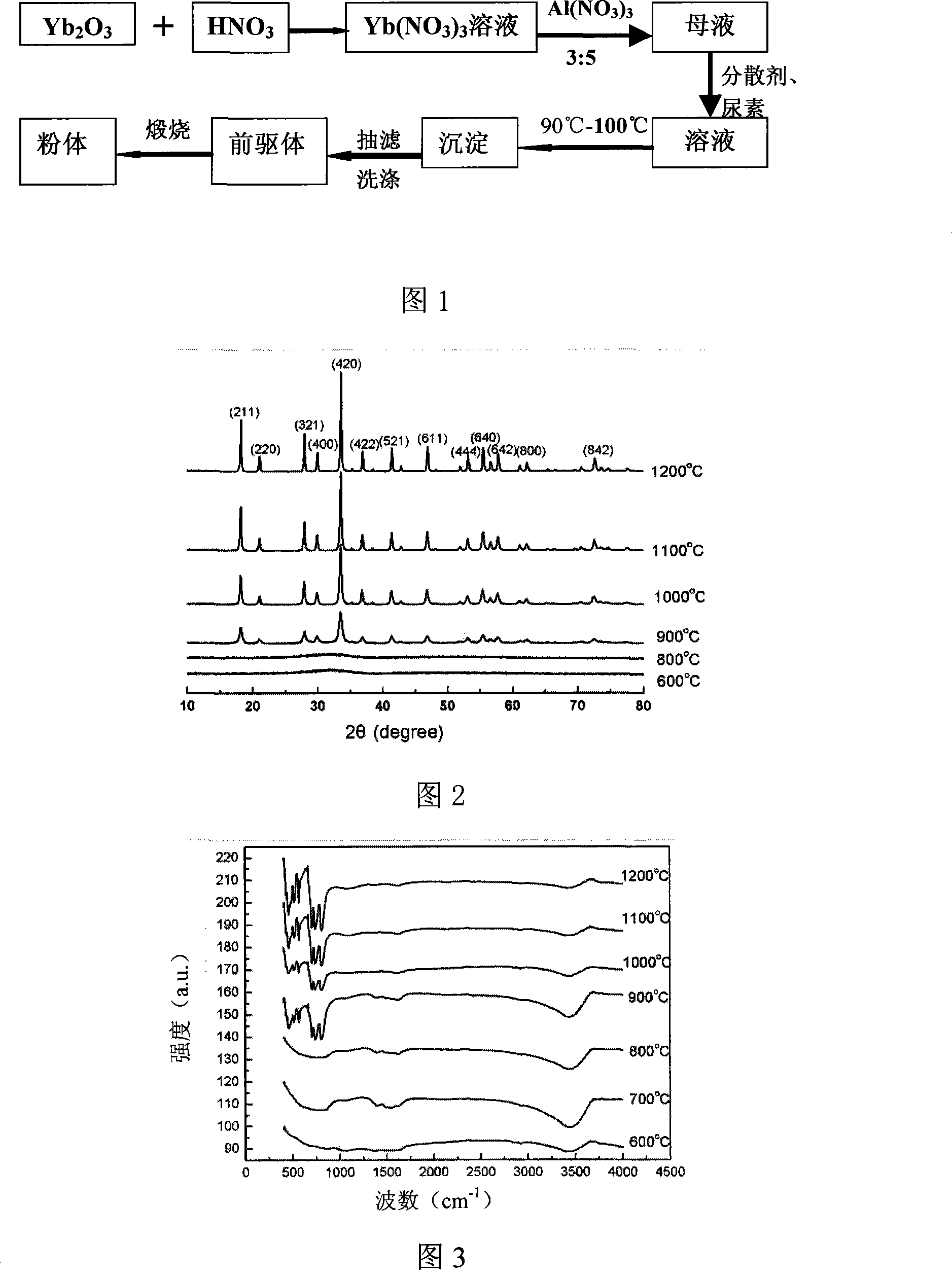

Method used

Image

Examples

Embodiment 1

[0027] High-purity commercial Yb with a purity of 99.99% 2 o 3 The powder was dissolved in nitric acid, and deionized water was added to make Yb(NO 3 ) 3 Solution 300ml. Purity is 99.9% Al (NO 3 ) 3 9H 2 O was prepared into 500ml of a 1 M solution, and the two solutions were mixed and fully stirred evenly to obtain the mother liquor. Add deionized water to the mother liquor to make the mother liquor reach 1000ml, and add 2 grams of HPC as a dispersant. Add 720 grams of urea and stir well. Heat the mother liquor to 95°C with an oil bath, increase the stirring speed, keep the temperature for 2 hours, and then drop to room temperature. Wash 5 times with deionized water in a suction filtration device, then wash 3 times with absolute ethanol, and dry the product obtained by suction filtration in a drying oven at 120° C. for 24 hours. The dried precursor is calcined in air at 900°C-1200°C for 2 hours.

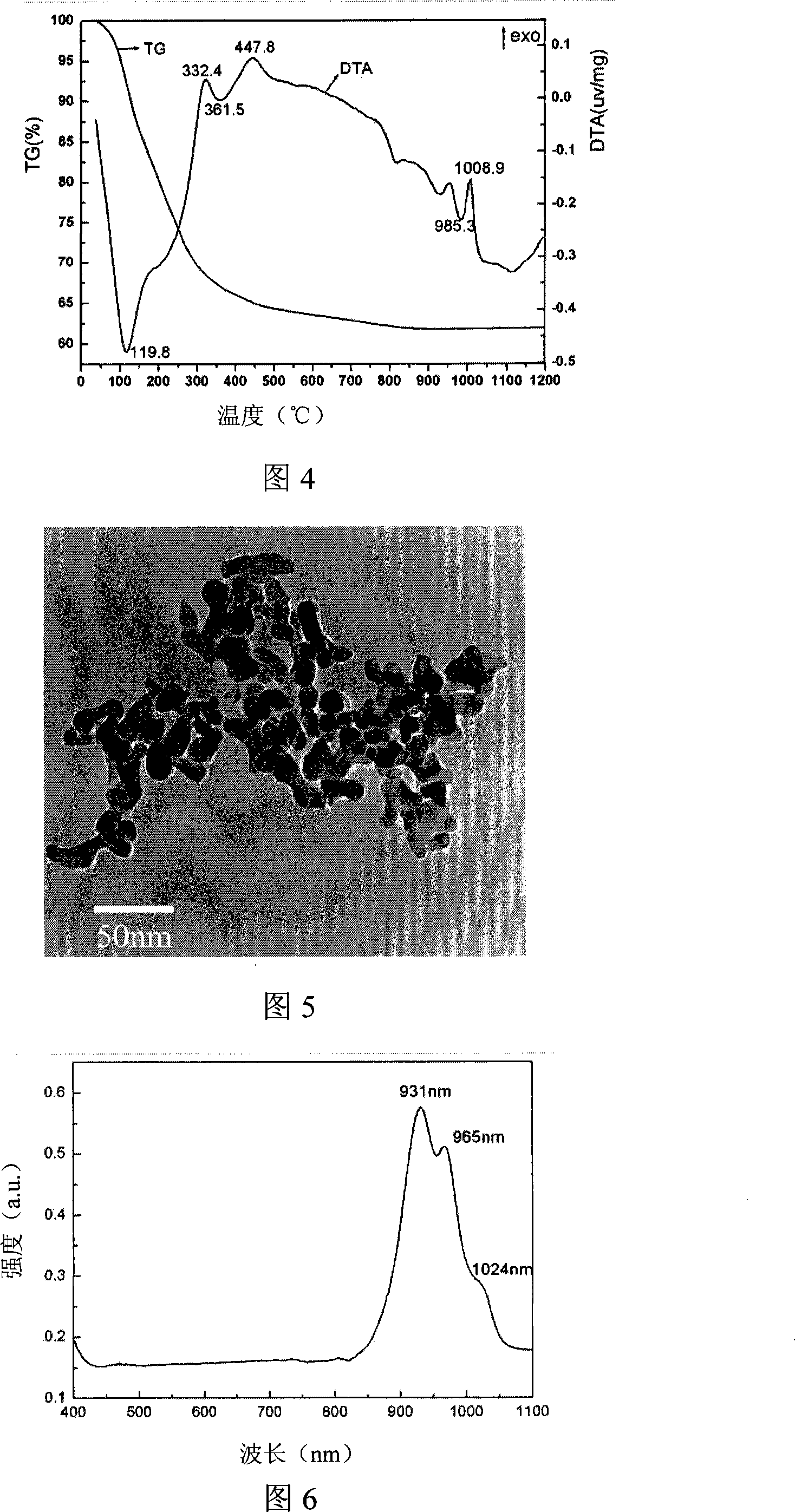

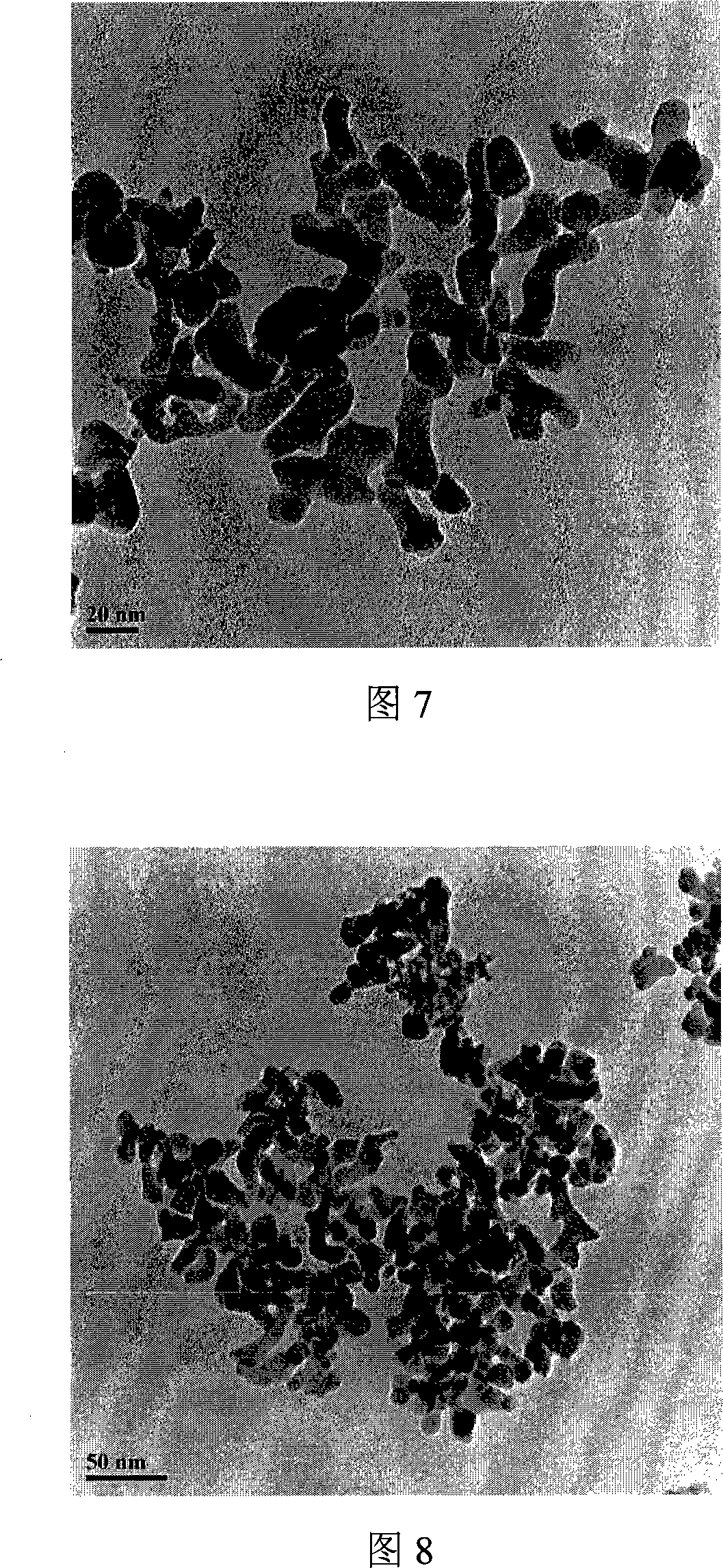

[0028] Figure 2 is the XRD pattern of the precursor after calcination a...

Embodiment 2

[0032] High-purity commercial Yb with a purity of 99.99% 2 o 3 The powder was dissolved in nitric acid, and deionized water was added to make Yb(NO 3 ) 3 Solution 300ml. Purity is 99.9% Al (NO 3 ) 3 9H 2 O was prepared into 250ml of a 2M solution, and the two solutions were mixed and fully stirred evenly to obtain a mother liquor. Add deionized water in mother liquor, make mother liquor reach 800ml, and add 1 gram (NH 4 ) 2 SO 4 as a dispersant. Add 720 grams of urea and stir well. The mother liquor was heated to 100°C with an oil bath, and the stirring speed was accelerated, kept at 100°C for 5 hours, and then lowered to room temperature. Wash 6 times in a suction filtration device with deionized water, then wash 3 times with absolute ethanol, and dry the product obtained by suction filtration in a drying oven at 120° C. for 20 hours. The dried precursor is calcined in air at 900°C-1200°C for 2 hours. After calcining at 900°C, a pure-phase YbAG powder is obtained,...

Embodiment 3

[0034] High-purity commercial Yb with a purity of 99.99% 2 o 3 The powder was dissolved in nitric acid, and deionized water was added to make Yb(NO 3 ) 3 Solution 600ml. Purity is 99.9% Al (NO 3 ) 3 9H 2 O was prepared into 500ml of 2M solution, and the two solutions were mixed and fully stirred evenly to obtain the mother liquor. Add deionized water to the mother liquor to make the mother liquor reach 1500ml, and add 5 grams of HPC as a dispersant. Add 1440 grams of urea and stir well. The mother liquor was heated to 100°C with an oil bath, and the stirring speed was accelerated, kept at 100°C for 5 hours, and then lowered to room temperature. Wash 5 times with deionized water in a suction filtration device, then wash 3 times with absolute ethanol, and dry the product obtained by suction filtration in a drying oven at 120° C. for 24 hours. The dried precursor is calcined in air at 900°C-1200°C for 2 hours. After calcining at 900°C, a pure-phase YbAG powder is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com