Method for treating Cr6+ in waste water and method for preparing montmorillonite-base nano magnetite used thereof

A montmorillonite-based, nano-magnet technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as secondary pollution and inability to restore hexavalent chromium, and achieve The effect of easy recovery, strong adsorption, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

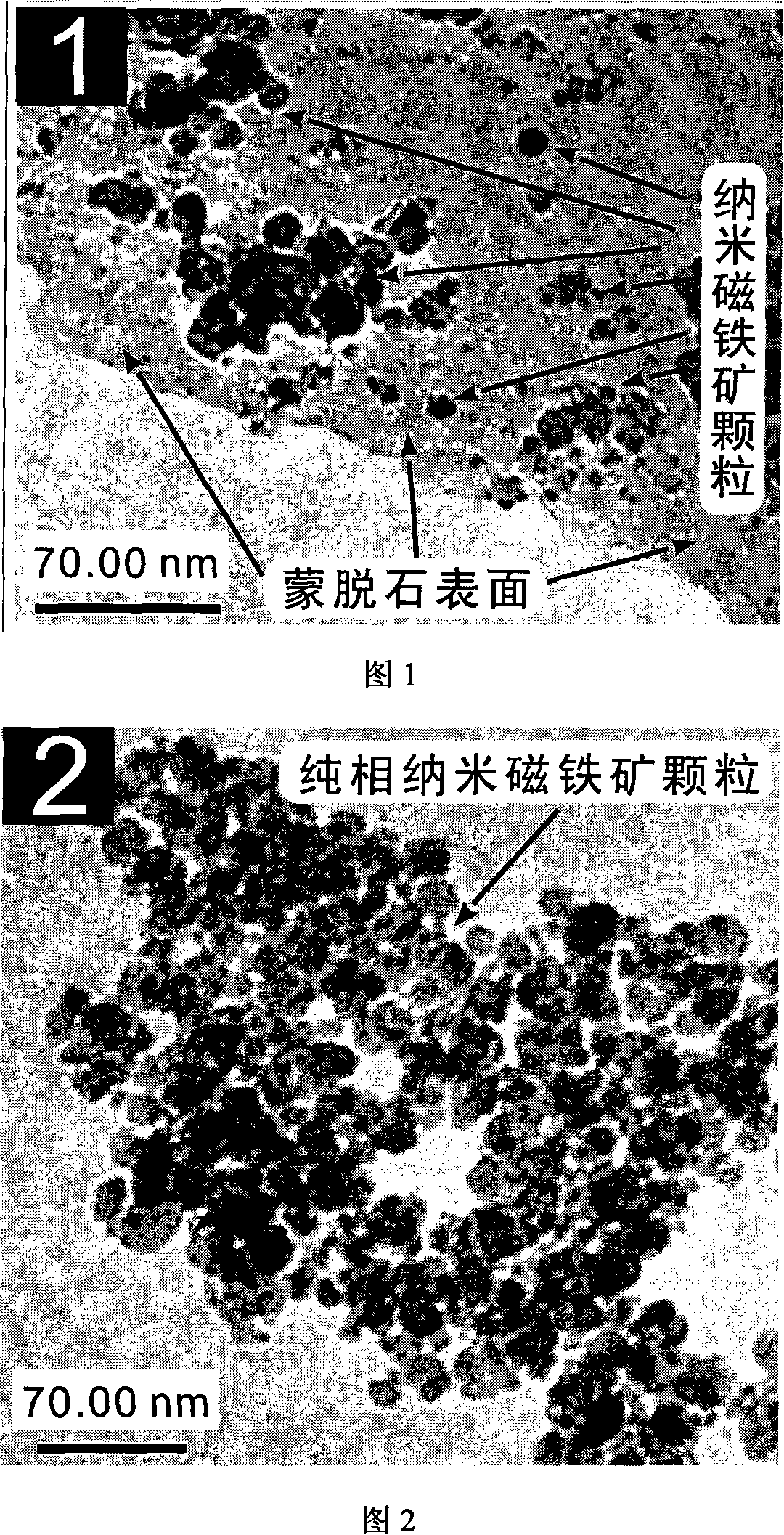

[0021] Example 1: Preparation of montmorillonite-based nano-magnetite adsorption material

[0022] 1) Weigh 170g FeCl 3 ·6H 2 O with 122gFeCl 2 4H 2 O, placed in a reactor filled with 5L of distilled water, stirred to dissolve.

[0023] 2) Heat the suspension to 60°C and keep it warm; under continuous stirring conditions, slowly add ammonia solution with a concentration of 10% (mass percentage) into the suspension, and stop dripping when the pH value of the suspension reaches 9. Add, continue to keep warm, stir for 2 hours.

[0024] 3) Centrifuging the suspension, and centrifuging and rinsing the magnetite wet precipitate with distilled water for 6 times, so that the pH value of the centrifuged supernatant is neutral. Then, 3 L of 0.01 mol / L hydrochloric acid was added to the obtained magnetite wet precipitate, fully stirred to disperse it evenly, and then the precipitate was centrifuged.

[0025] 4) Add 2 L of distilled water to the separated precipitate and stir thorou...

Embodiment 2

[0030] Potassium dichromate (K 2 Cr 2 o 7 ) for Cr 6+ source, formulated Cr 6+300ml of simulated wastewater with a concentration of 200mg / L and a pH value of 3.0. Weigh 36.6 g of the montmorillonite-based nano-magnetite adsorption material prepared in Example 1, add it to the prepared wastewater, stir for 5 minutes, and let stand for 15 minutes. Then use a common circular magnet with a diameter of 16cm to absorb the precipitate to achieve solid-liquid separation. After testing, the pH of the treated water is neutral, where Cr 6+ The concentration is lower than 0.01mg / L, which meets the discharge standard.

Embodiment 3

[0032] Potassium dichromate (K 2 Cr 2 o 7 ) for Cr 6+ source, formulated Cr 6+ 600ml of simulated wastewater with a concentration of 100mg / L and a pH value of 6.0. Weigh 68.2 g of the montmorillonite-based nano-magnetite adsorption material prepared in Example 1, add it into the prepared wastewater, stir for 5 minutes, and let stand for 15 minutes. Then use a common circular magnet with a diameter of 16cm to absorb the precipitate to achieve solid-liquid separation. After testing, the pH of the treated water is neutral, where Cr 6+ The concentration is lower than 0.01mg / L, which meets the discharge standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com