Method for preparing amorphous biological activity superfine powder

A bioactive, ultra-fine powder technology, applied in the field of biomedical materials, can solve problems such as difficult preparation of nano-scale powders, and achieve the effects of convenient preparation, avoiding agglomeration, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

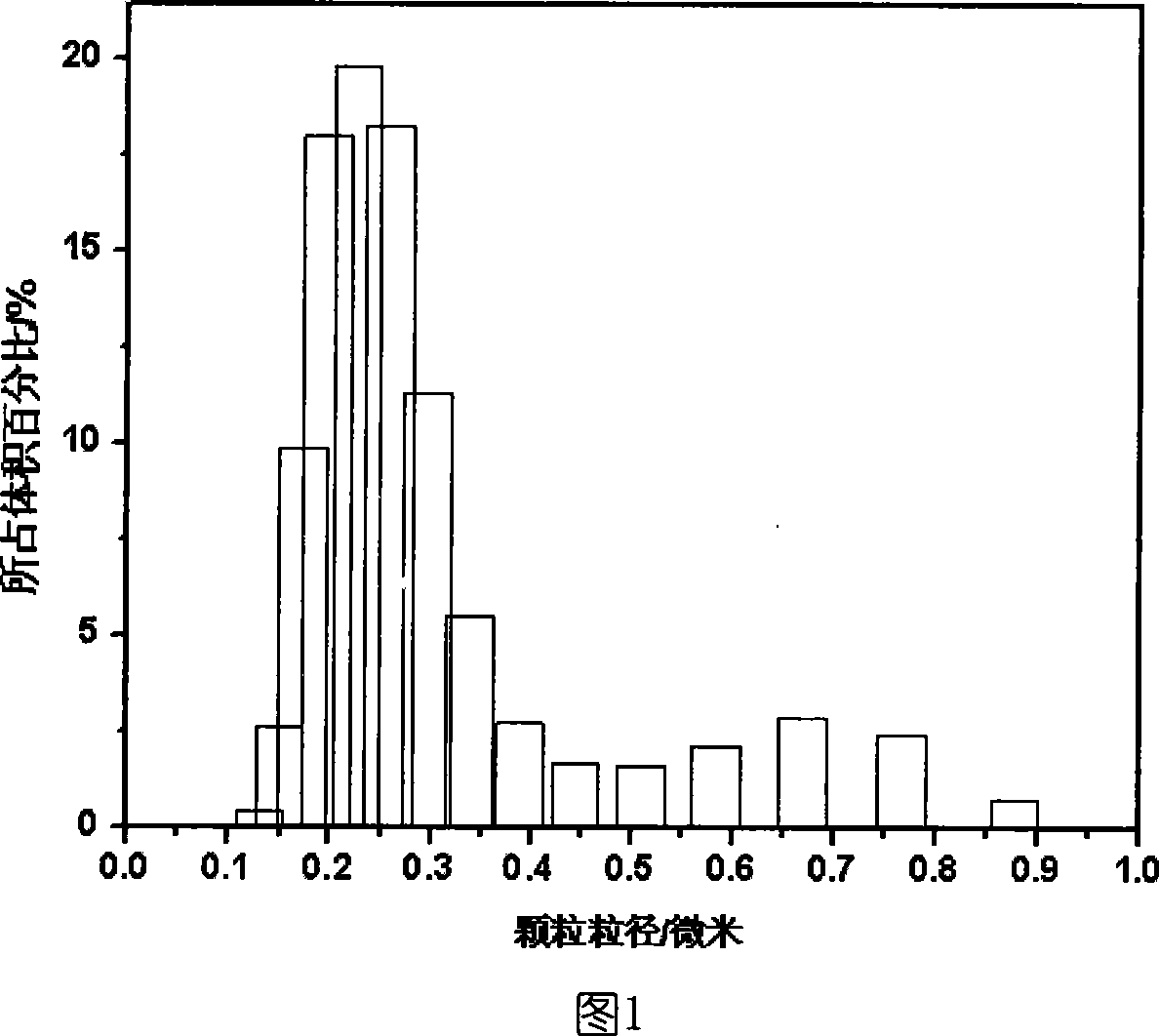

Image

Examples

Embodiment 1

[0020] To prepare amorphous bioactive ultrafine powder, follow the steps below:

[0021] (1) Ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate are added successively in the deionized aqueous solution containing the catalyst, and after fully stirring evenly, a transparent, uniform and stable sol is obtained, and the pH value of the solution is adjusted to 1 with hydrochloric acid; , the molar ratio of ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate is 60:4:36, and the molar ratio of deionized water to ethyl orthosilicate is 8:1;

[0022] (2) aging the sol obtained in step (1) statically at room temperature for 4 days to form a wet gel;

[0023] (3) placing the wet gel obtained in step (2) in a drying oven at 80°C for 2 days to obtain a dry gel;

[0024] (4) Place the xerogel obtained in step (3) in an electric furnace, and heat-treat at 600°C to obtain a granular sol-gel bioactive material;

[0025] (5) Mixing the granular sol...

Embodiment 2

[0028] To prepare amorphous bioactive ultrafine powder, follow the steps below:

[0029] (1) Ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate are added successively in the deionized aqueous solution containing catalyst, and after fully stirring evenly, a transparent, uniform and stable sol is obtained, and the pH value of the solution is adjusted to 3 with nitric acid; , the molar ratio of ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate is 80:4:16, and the molar ratio of deionized water to ethyl orthosilicate is 12:1;

[0030] (2) aging the sol obtained in step (1) statically at room temperature for 7 days to form a wet gel;

[0031] (3) placing the wet gel obtained in step (2) in a drying oven at 140° C. for 3 days to obtain a dry gel;

[0032] (4) placing the xerogel obtained in step (3) in an electric furnace, and heat-treating at 700°C to obtain granular sol-gel bioactive materials;

[0033] (5) The granular sol-gel bioa...

Embodiment 3

[0036] To prepare amorphous bioactive ultrafine powder, follow the steps below:

[0037] (1) Add ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate in sequence to the deionized aqueous solution containing the catalyst, stir well to obtain a transparent, uniform and stable sol, and adjust the pH of the solution to 2 with hydrofluoric acid ; Wherein, the mol ratio of ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate is 70:4:20, and the mol ratio of deionized water and ethyl orthosilicate is 10:1;

[0038] (2) aging the sol obtained in step (1) statically at room temperature for 6 days to form a wet gel;

[0039] (3) placing the wet gel obtained in step (2) in a drying oven at 100°C for 2.5 days to obtain a dry gel;

[0040] (4) placing the xerogel obtained in step (3) in an electric furnace, and subjecting it to heat treatment at 650° C. to obtain granular sol-gel bioactive materials;

[0041] (5) The granular sol-gel bioactive ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com