Method for preparing graft polymer containing carbon nano-tube

A technology of grafted polymers and carbon nanotubes, which is applied in fiber modification, spinning, and plastic fields, can solve problems such as difficult bonding, large surface energy, and influence on uniform dispersion, so as to improve dissolution and dispersion performance and increase interface The effect of binding force and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

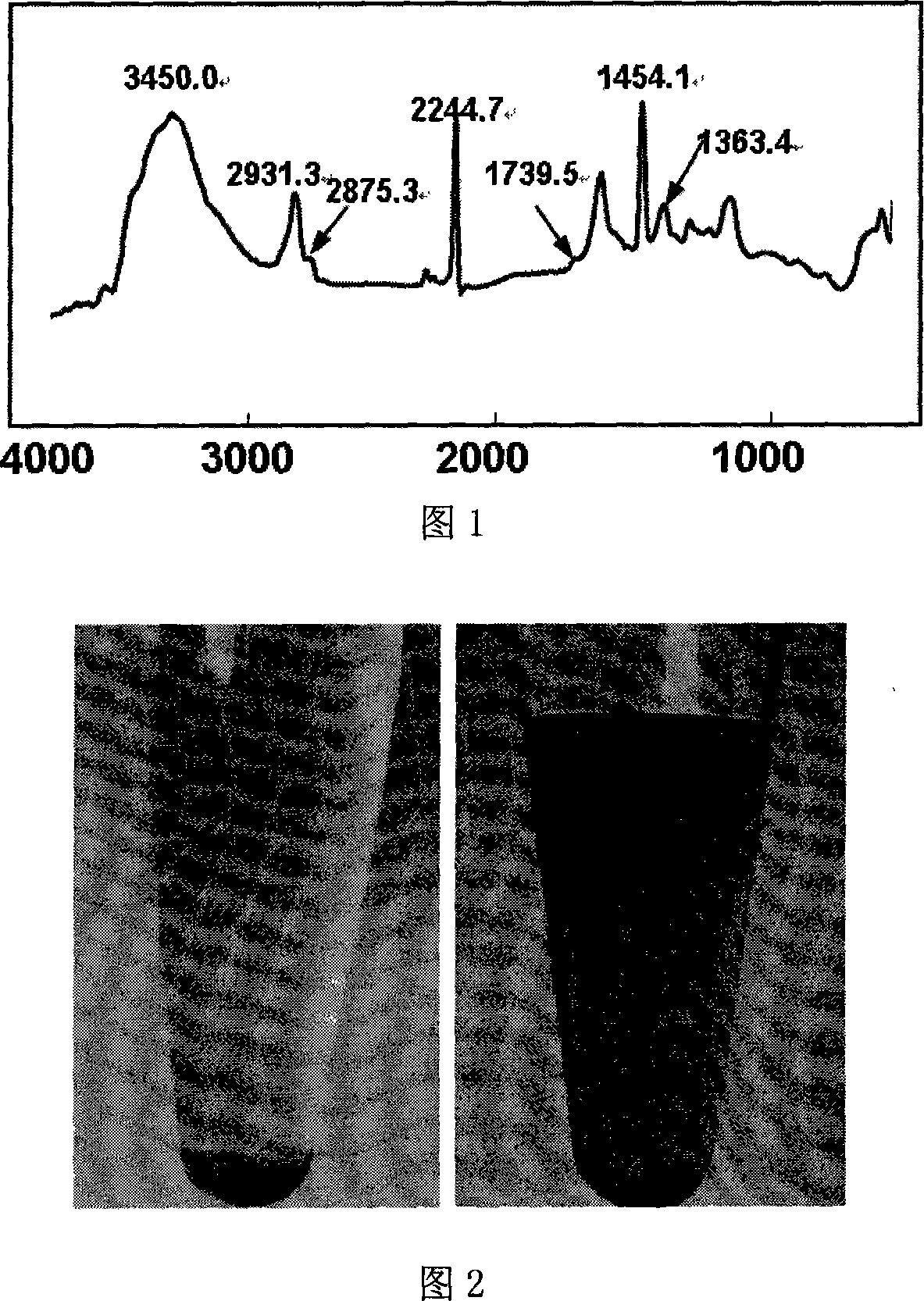

[0032] Example 1: Using multi-walled carbon nanotubes as starting materials, after acidification, acyl chloride and alcoholization, hydroxyl groups are introduced on the surface of carbon nanotubes, and then a redox initiation system is formed with cerium ions to initiate the polymerization of acrylonitrile to obtain carbon-containing Nanotube-grafted polymers.

[0033] Step 1: Add 3.0g of multi-walled carbon nanotubes (MWNTs), 40mL of nitric acid, and 120mL of sulfuric acid into a 1000mL flask with a condenser, which needs to be equipped with a strong stirring device; immerse the flask in an ultrasonic bath (59KHz) for 10min It is well dispersed; then, heating in an oil bath, reflux reaction for 110min, and at the same time, the heating temperature is gradually increased from 90°C to 120°C, and the thick brown gas generated during this period is collected by a plastic conduit through a condenser and treated with a sodium hydroxide solution; After the reaction is completed and...

Embodiment 2

[0038] Step 1: Add 3.0g of multi-walled carbon nanotubes (MWNTs), 60mL of hydrogen peroxide, and 120mL of sulfuric acid into a 1000mL flask with a condenser, which must be equipped with a strong stirring device; immerse the flask in an ultrasonic bath (40KHz) 48h to make it well dispersed; then, heat in an oil bath and reflux for 48h, while the heating temperature gradually rises from 90°C to 150°C. Treatment: After the reaction is completed, after cooling to room temperature, the reaction mixture is first diluted, separated by a centrifuge, and then vacuum filtered through a 0.22 μm polyvinylidene fluoride membrane, washed with deionized water several times until the pH value is close to 7; vacuum at 25°C Drying at lower temperature for 48h to obtain acidified carbon nanotubes;

[0039] Step 2: Add 0.28g of acidified MWNTs-COOH and 15mL of excess phosphorus trichloride to the ampoule with a stirring and condensing reflux device, and immerse the flask in an ultrasonic bath (40...

Embodiment 3

[0043] Step 1: Add 3.0g of multi-walled carbon nanotubes (MWNTs) and 180mL of concentrated nitric acid into a 1000mL flask with a condenser, which must be equipped with a strong stirring device; immerse the flask in an ultrasonic bath (100KHz) for 24 hours to make it well Disperse; then, heat in an oil bath and reflux for 24 hours, while the heating temperature gradually rises from 25°C to 100°C. During this period, the thick brown gas generated is collected by a plastic conduit through a condenser and treated with sodium hydroxide solution; the reaction is over , after cooling to room temperature, the reaction mixture was first diluted, separated with a centrifuge, then vacuum filtered through a 0.22 μm polyvinylidene fluoride membrane, washed with deionized water several times until the pH value was close to 7; dried in an oven at 100°C 0.5h, obtain acidified carbon nanotubes;

[0044] Step 2: Add 0.28g of acidified MWNTs-COOH and 15mL of excess phosphorus tribromide to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com