Extraction method for ferulic acid esterase

A technology of ferulic acid esterase and enzyme liquid, applied in the direction of hydrolytic enzymes, etc., can solve the problem that the digestion utilization rate does not exceed 50%, and achieve the effect of high practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The processing of embodiment 1 beef cattle rumen liquid

[0023] In the early morning when the cattle were fasting, 1200mL of rumen fluid was extracted from the rumen through the rumen cannula of the cattle, filtered through four layers of medical gauze, and the filtrate was centrifuged at 20,000×g at 4°C for 30 minutes to remove bacterial precipitates, and 1000mL of the supernatant was collected for supernatant. Filtration and other next procedures.

[0024] Take the supernatant and first pass it through the ultrafiltration membrane ultrafiltration with a molecular weight cut-off of 100KDa, collect the part 100KDa, and prepare To obtain a higher-purity enzyme solution, use ice to control the temperature of the enzyme solution at 5°C, and the enzyme recovery rate can be as high as 55%.

[0025] Then, 100 mL of the concentrate sample obtained by ultrafiltration with a molecular weight between 10-100 KDa was heated at 60°C for 30 minutes, and centrifuged at 10,000×g at 4...

Embodiment 2

[0026] The processing of embodiment 2 concentrate samples

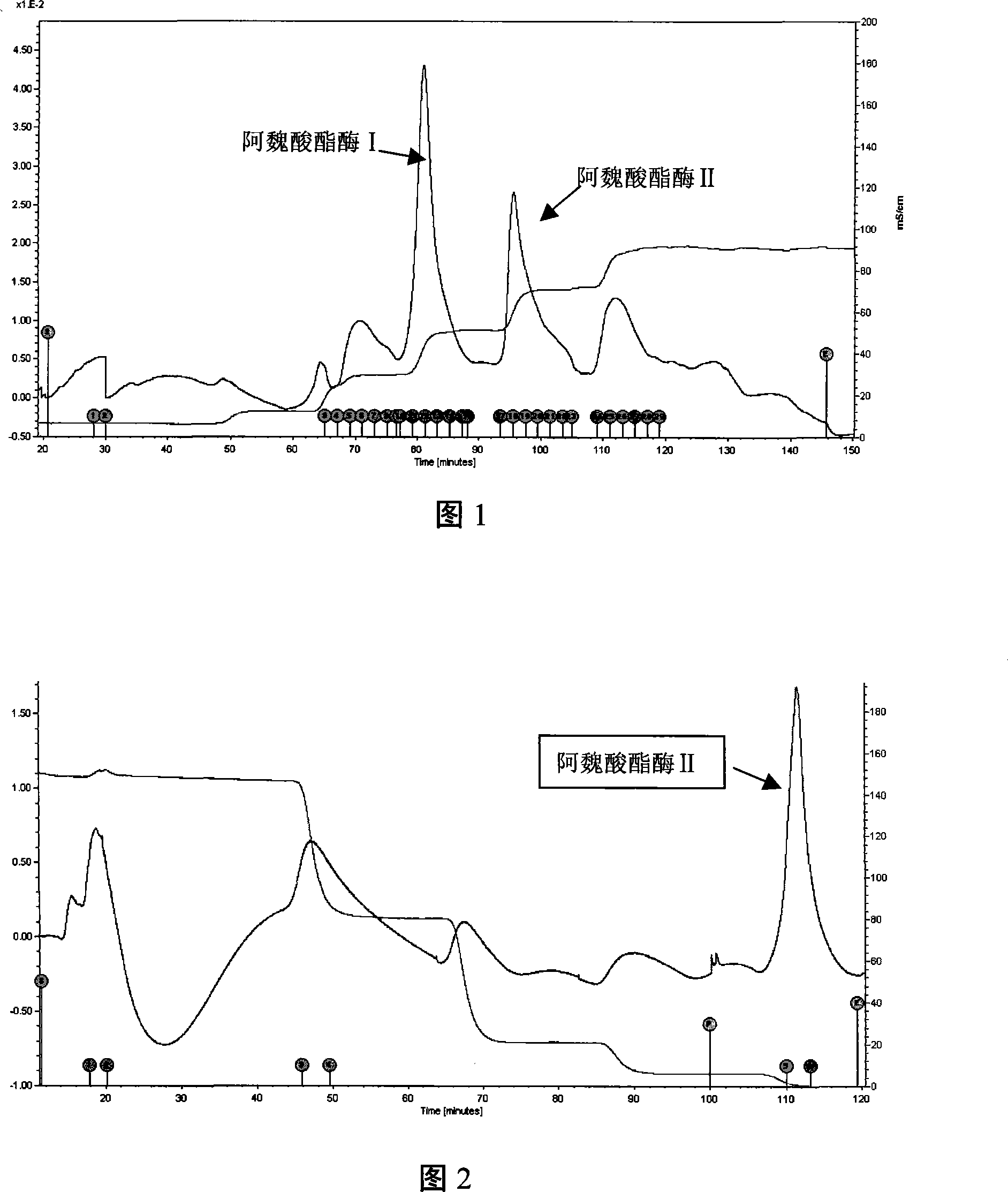

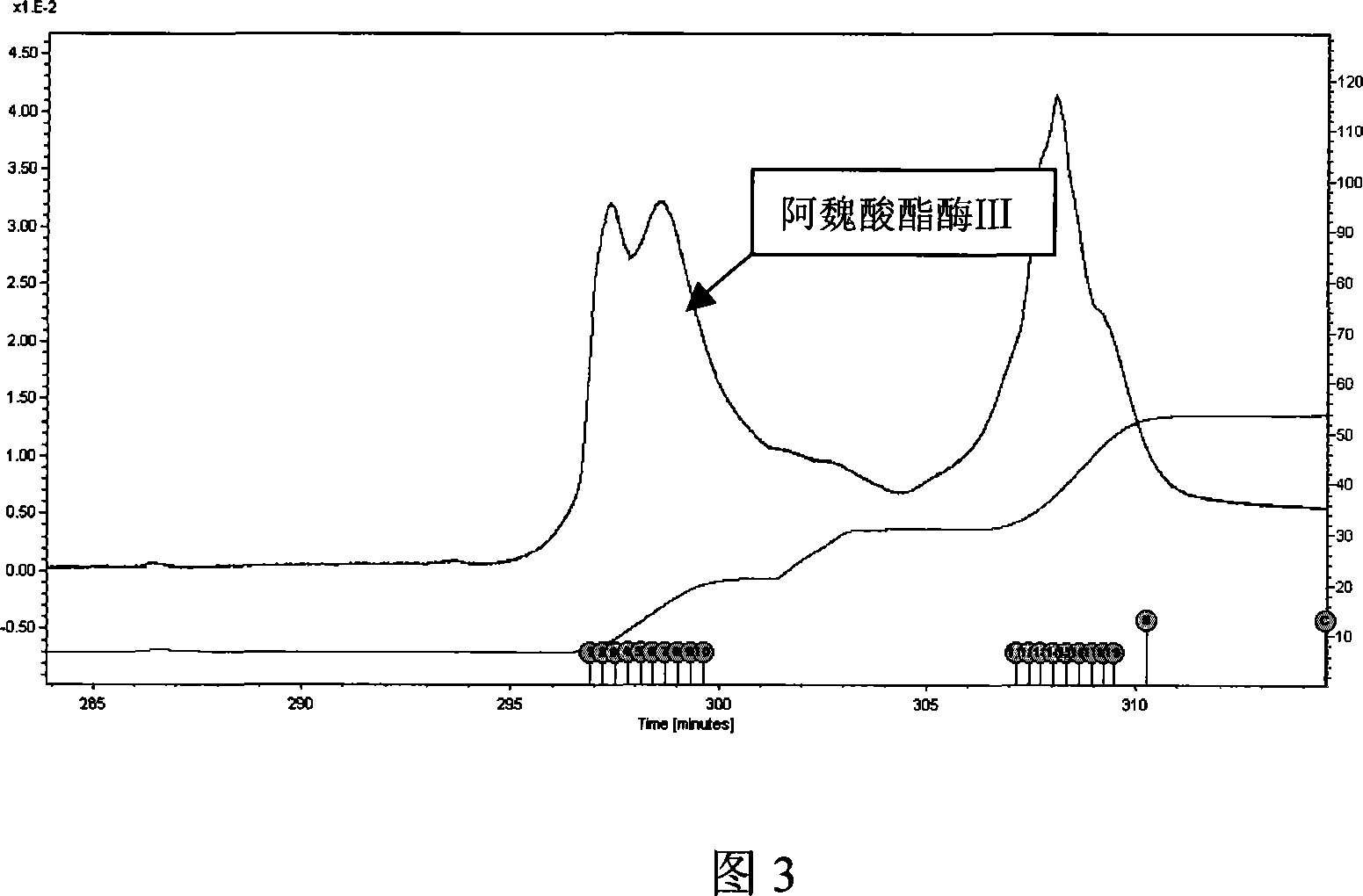

[0027] Dialyze 100mL of the concentrated solution with a molecular weight > 100KDa and the concentrated solution with a molecular weight between 10-100KDa to remove denatured proteins, concentrate, add an equal volume of 200mM sodium phosphate buffer (pH7) and 2 times the volume of deionized water, and mix well. Take 0.8mL samples with molecular weight > 100KDa and separate them with strong anion exchange chromatography column Q Sepharose Fast Flow column at a speed of 2mL / min, using 50mM sodium phosphate buffer (pH7) as solution A, 50mM sodium phosphate buffer containing 1M NaCl Solution (pH7) is B solution. Unbound substances were eluted with 30mL A solution, and bound proteins were eluted with a five-step gradient: 30mL 10% B solution, 30mL 25% B solution, 30mL 50% B solution, 30mL 75% B solution, 100mL B solution to elute bound proteins, Collect the fraction with ferulic acid esterase activity, dialyze, concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com