Method for manufacturing silicon crystal plate for solar battery

A technology of solar cells and silicon wafers, applied in chemical instruments and methods, circuits, crystal growth, etc., can solve the problems of low material utilization rate, inversion, silicon wafers that cannot be used to prepare solar cells, etc., to improve the utilization rate , high material utilization, and the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

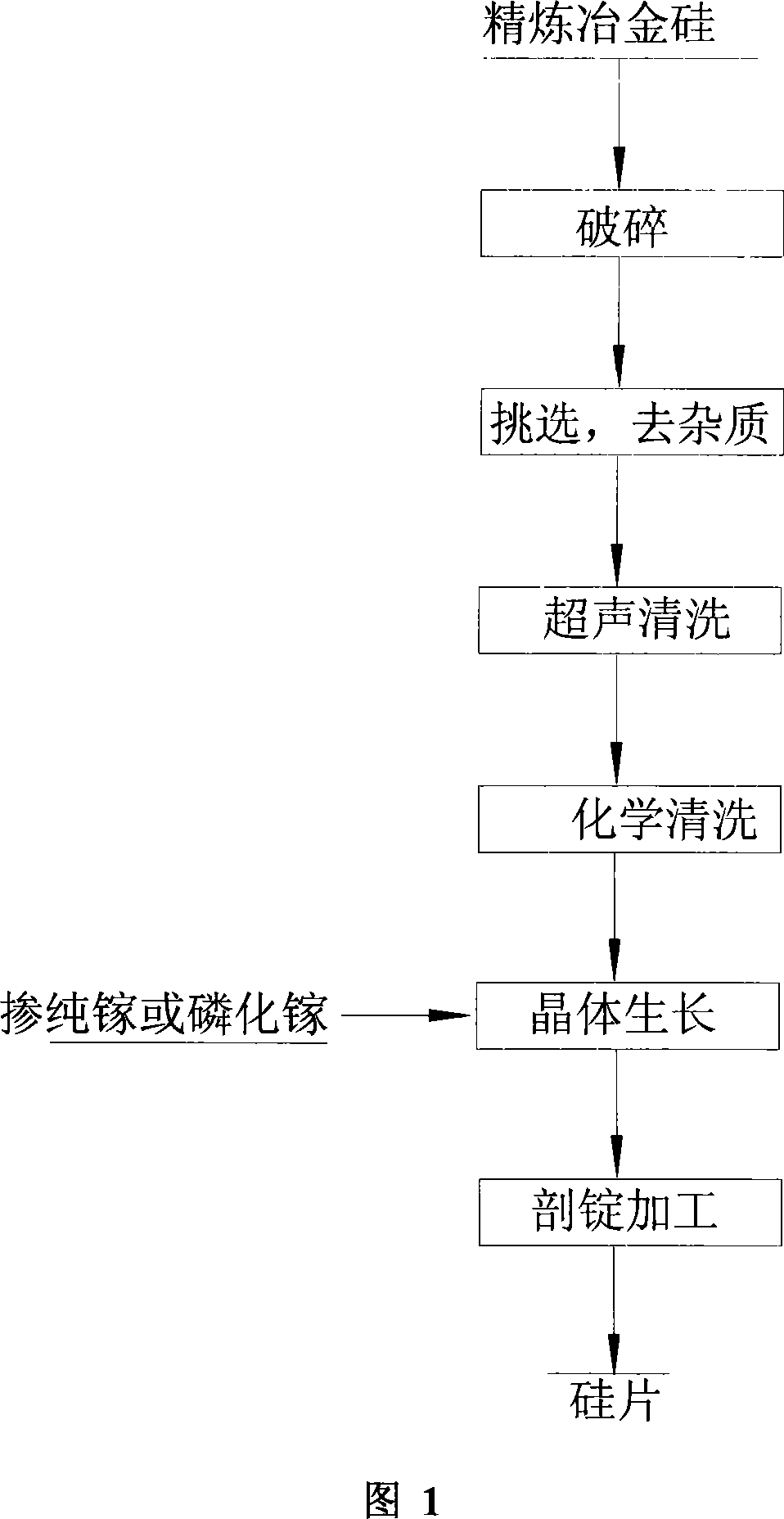

[0017] Embodiment 1: Referring to accompanying drawing 1, a kind of preparation method of the silicon wafer that is used for solar cell, after refined metallurgical silicon is crushed to appropriate size (if the interlayer of incoming material contains more impurity, the diameter of the broken silicon block No more than 4cm), after preliminary selection to remove impurities, put it into an ultrasonic cleaner for cleaning, take it out and put it into a mixed acid solution of nitric acid and hydrofluoric acid for cleaning to remove surface impurities, and then put it into a high-purity quartz crucible , add gallium with an atomic concentration of 12.0ppma, put the quartz crucible into the graphite crucible in the single crystal furnace, then evacuate the single crystal furnace, and then fill it with argon as a protective gas, heat the furnace body, and the heating temperature exceeds The melting point of the silicon material melts the raw material in the crucible and keeps it war...

Embodiment 2

[0024] Example 2: A method for preparing silicon wafers for solar cells. After crushing refined metallurgical silicon to an appropriate size, after preliminary selection to remove impurities, put it into an ultrasonic cleaner for cleaning, and then put nitric acid and hydrogen into it after taking it out. Fluoric acid mixed acid solution to remove surface impurities; then put into a high-purity quartz crucible, and add gallium with an atomic concentration of 12.2ppma, place the quartz crucible on a heat exchange table (polycrystalline growth furnace), and Vacuumize to reduce the pressure to 0.05-0.1mbar, feed argon as a protective gas, and maintain the pressure in the furnace at about 400-600mbar; slowly heat to about 1200-1300°C, and the process takes 4 to 5 hours; gradually increase the heating power , so that the temperature in the quartz crucible reaches about 1500 ° C, the silicon raw material begins to melt, and the heat preservation is completed until the chemical materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com